5 32 welding rod 7018 supplier

The Importance of Selecting the Right Supplier for 5% 2032 Welding Rod 7018

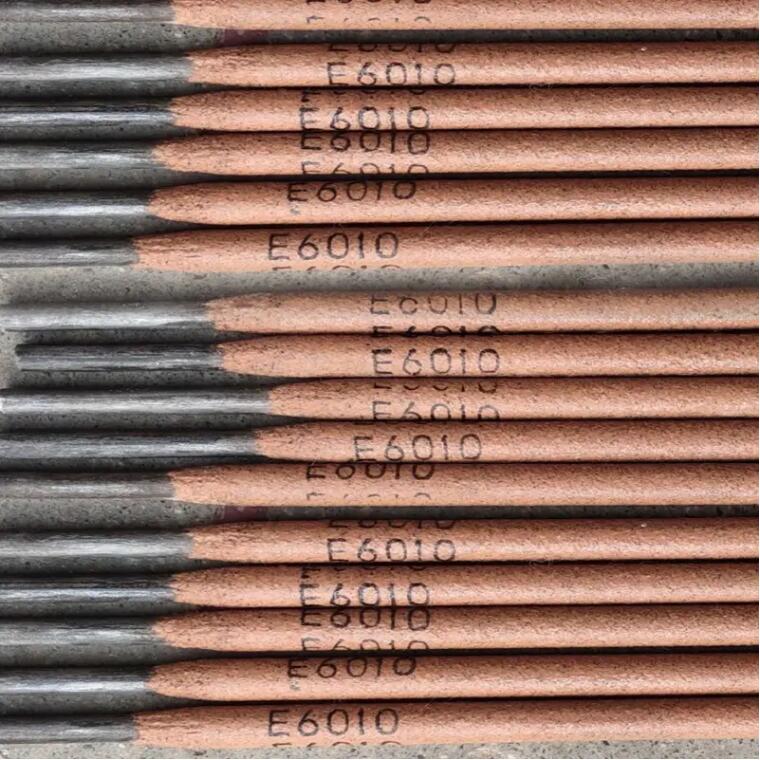

Welding is a crucial industrial process that requires precision, skill, and the right materials. One of the most essential components in welding is the welding rod, and for specific applications, the 5% 2032 welding rod 7018 has proven to be a reliable choice. However, the effectiveness of this welding rod largely depends on selecting the right supplier. In this article, we will explore the characteristics of the 5% 2032 welding rod 7018 and the importance of choosing a reputable supplier.

Understanding the 5% 2032 Welding Rod 7018

The 5% 2032 welding rod 7018 is a low-hydrogen electrode designed for use in welding high-strength steels. It is known for its excellent arc stability, ease of use, and ability to produce high-quality welds. The 7018 designation refers to the tensile strength of the weld – 70,000 psi – and the “1” indicates that it is suitable for all positions of welding. The added 5% signifies the composition of the electrode, which includes 5% iron powder, enhancing the overall performance by increasing deposition rates.

This rod is often favored in the construction, shipbuilding, and heavy machinery industries for fabricating structural components, tanks, and pipelines. Its properties, such as low hydrogen content, minimize the risk of cracking, making it an ideal choice for critical applications involving carbon and low-alloy steels.

The Role of Suppliers

Finding a reliable supplier for welding rods, particularly for specialized products like the 5% 2032 welding rod 7018, is vital. The supplier's expertise and understanding of the product can significantly influence the quality of the welding process and the final output.

5 32 welding rod 7018 supplier

1. Quality Assurance A reputable supplier performs rigorous quality checks on their products to ensure compliance with industry standards. When selecting a supplier, it is essential to inquire about their quality assurance processes. This includes certifications and testing procedures that verify the performance characteristics of the welding rods.

2. Product Availability The supply chain for welding materials can be affected by global market fluctuations. A good supplier will have a stable inventory and the ability to provide timely deliveries, thus minimizing downtime in production. It's vital to establish a long-term relationship with a supplier who understands your needs and can quickly respond to them.

3. Technical Support Not all welding applications are the same, and specific projects may require particular advice on the best practices for using a 5% 2032 welding rod 7018. A knowledgeable supplier can offer consulting services and technical support, helping you choose the right products for your specific tasks, thus optimizing both the process and the results.

4. Competitive Pricing While cost should not be the sole factor, it is undoubtedly an important consideration. A reliable supplier will offer competitive pricing without compromising on quality. They should be transparent about pricing structures and able to provide bulk purchasing options, which can lead to cost savings for your business.

5. Reputation and Reviews Before settling on a supplier, researching their reputation in the industry is essential. Customer reviews and testimonials can provide insights into their reliability, customer service, and overall satisfaction. A supplier with a strong track record is more likely to meet your expectations.

Conclusion

The choice of a supplier for 5% 2032 welding rod 7018 plays a crucial role in the success of welding operations. Quality, availability, technical support, competitive pricing, and reputation are all critical factors to consider when making your decision. By partnering with a trustworthy supplier, you can ensure that your welding projects achieve the desired standards of quality, safety, and efficiency. Ultimately, investing time in selecting the right supplier will lead to long-term benefits and success in your welding endeavors.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025