soldadura electrodo factory

The Role of Electrode Welding in Modern Industries

Welding is a pivotal process in the manufacturing and construction sectors, serving as a technique to fuse materials, primarily metals, together. One of the most widely used methods of welding is electrode welding, which has gained immense popularity across various industries due to its efficiency and adaptability. This article delves into the significance of electrode welding factories, exploring their processes, applications, and the future of this essential technology.

Understanding Electrode Welding

Electrode welding, often referred to as arc welding, utilizes an electric arc to melt and join the workpieces together. In this process, an electrode is used to generate the arc, and the electrode material often serves as a filler for the weld joint. The heat produced by the arc is intense, often exceeding temperatures of 6,500 degrees Fahrenheit, enabling the rapid melting of metal surfaces.

This method is favored for its versatility; it can be applied in various environments, from heavy industry to specialized fabrication projects. Factories specializing in electrode welding are responsible for producing the electrodes, setting the standards for quality and performance in the market.

The Production Process in Electrode Welding Factories

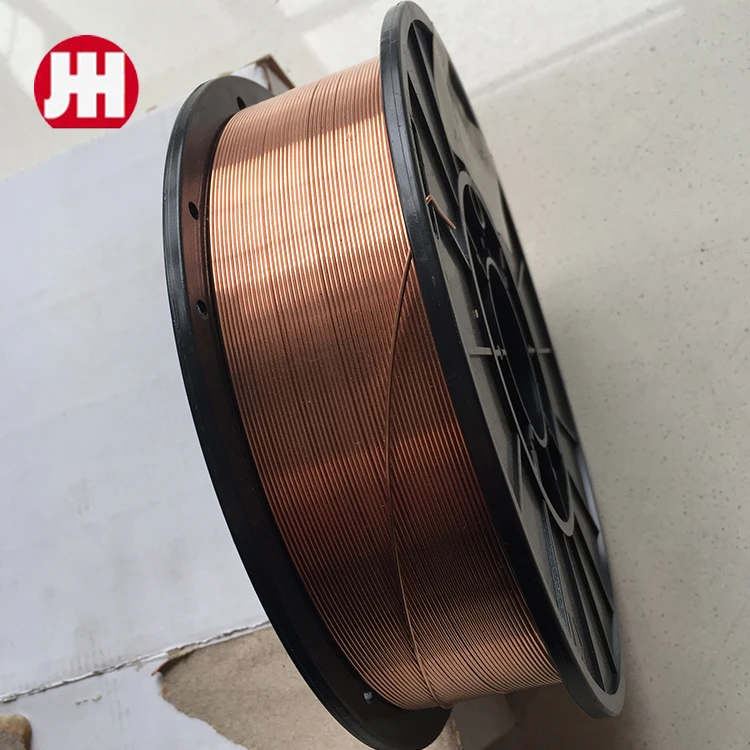

Electrode welding factories focus on creating high-quality welding electrodes that cater to diverse industrial requirements. The production process begins with sourcing raw materials, which typically include high-grade alloys and fillers. Rigorous quality control measures ensure that these materials meet specific industry standards.

Once the raw materials are obtained, the manufacturing process involves several stages

1. Coating Application The core wire is coated with materials that enhance its properties, such as improving stability and reducing spatter. Different coatings can provide unique characteristics, allowing for adjustments based on specific welding tasks.

2. Drawing The coated wire is then drawn down to the desired diameter, ensuring uniformity and consistency across the production line.

soldadura electrodo factory

3. Cutting and Packaging Once the electrodes are formed, they are cut to length and packaged carefully to prevent damage during transportation.

Quality assurance tests are conducted throughout the manufacturing process, including tensile strength tests and corrosion resistance assessments, guaranteeing that the final products can withstand harsh welding conditions and deliver reliable performance.

Applications of Electrode Welding

Electrode welding is prevalent in a diverse range of applications. The construction industry employs it extensively for building structures, bridges, and pipelines, where robust joints are crucial for safety and integrity. Similarly, the automotive sector relies on electrode welding for assembling vehicles, ensuring that parts are securely joined to withstand operational stresses.

Other industries, such as shipbuilding and aerospace, also leverage electrode welding due to its ability to deliver strong, high-quality welds. The technology has evolved, adapting to various materials beyond traditional steel, including aluminum and stainless steel, which broadens its applicability in modern manufacturing.

Innovations and the Future of Electrode Welding

As industries evolve, so does the technology surrounding electrode welding. Innovations such as automated welding systems and robotic arms are transforming traditional practices. These advancements not only increase efficiency but also enhance precision, reducing the manual effort involved in welding tasks.

Moreover, the integration of artificial intelligence (AI) and machine learning into electrode welding processes promises to optimize performance by providing real-time monitoring and adjustments during the welding process. Environmental concerns also drive innovation, leading to the development of eco-friendly electrodes that minimize emissions and energy consumption.

Conclusion

In conclusion, electrode welding factories play a crucial role in the industrial landscape, offering high-quality welding solutions that power various sectors. As technology continues to advance, the methods and materials used in electrode welding are likely to become even more sophisticated, further enhancing their importance in modern manufacturing. By embracing innovation and maintaining stringent quality standards, electrode welding factories will remain at the forefront of welding technology, meeting the complex demands of the industry for years to come.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025