Feb . 11, 2025 09:40

Back to list

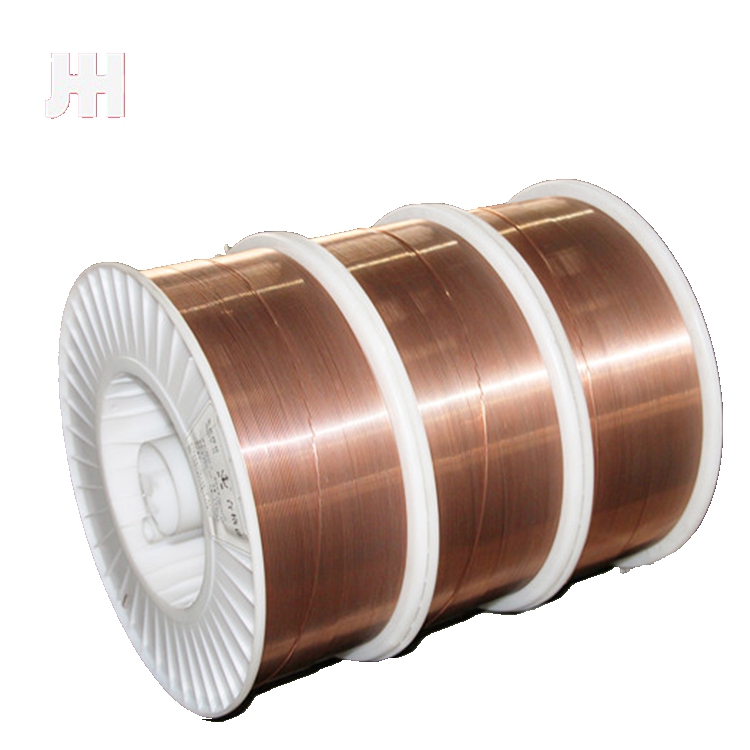

flux core welding wire 035

Understanding flux core welding wire and its applications can be immensely beneficial for both amateur and professional welders. Flux core wires, like the 0.035 inch variant, are indispensable in modern welding due to their versatility and efficiency. With a unique set of characteristics that make them suitable for various welding projects, this type of wire can help maximize productivity and ensure strong, reliable welds.

Trust in flux core welding wire is further reinforced by its cost-effectiveness. While the initial expense might be higher compared to solid wires, the absence of a need for additional shielding gas, and the efficiency of the welding process itself, lead to reduced operational costs over time. This makes it an attractive choice for both hobbyists and large-scale operations looking to optimize their budgets without sacrificing quality. The unique characteristics of flux core welding wire 0.035 make it essential for versatile welding practices. For beginners, learning how to effectively use this wire can open up new project possibilities, while seasoned professionals can enhance their weld quality and efficiency. The wire's ability to conform to different welding scenarios adds a layer of adaptability that is highly valued in dynamic working environments. For those who prioritize the combination of convenience and reliability in welding, flux core welding wire 0.035 stands as a powerful tool. The application possibilities are vast, from small, detailed welding tasks to large structural projects. This versatility, coupled with its robustness and dependability, ensures that it remains an indispensable resource in any welder's toolkit. Ultimately, the key to unlocking the full potential of flux core welding lies in understanding its properties and matching them with specific project requirements. Whether it's for repair work, DIY projects, or extensive industrial tasks, flux core welding wire 0.035 delivers both performance and reliability, trusted by experts and upheld by years of successful application.

Trust in flux core welding wire is further reinforced by its cost-effectiveness. While the initial expense might be higher compared to solid wires, the absence of a need for additional shielding gas, and the efficiency of the welding process itself, lead to reduced operational costs over time. This makes it an attractive choice for both hobbyists and large-scale operations looking to optimize their budgets without sacrificing quality. The unique characteristics of flux core welding wire 0.035 make it essential for versatile welding practices. For beginners, learning how to effectively use this wire can open up new project possibilities, while seasoned professionals can enhance their weld quality and efficiency. The wire's ability to conform to different welding scenarios adds a layer of adaptability that is highly valued in dynamic working environments. For those who prioritize the combination of convenience and reliability in welding, flux core welding wire 0.035 stands as a powerful tool. The application possibilities are vast, from small, detailed welding tasks to large structural projects. This versatility, coupled with its robustness and dependability, ensures that it remains an indispensable resource in any welder's toolkit. Ultimately, the key to unlocking the full potential of flux core welding lies in understanding its properties and matching them with specific project requirements. Whether it's for repair work, DIY projects, or extensive industrial tasks, flux core welding wire 0.035 delivers both performance and reliability, trusted by experts and upheld by years of successful application.

Previous:

Next:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025