Production Description

The Welding Wire ER70S-6 is 500MPa level carbon steel wire. It take CO2 or 80%Ar + 20%CO2 gas shielded arc welding. The welding

spatter is small, and it has beautiful appearance, high cladding efficiency and small weld metal porosity sensibility. The welding

technology of all positions is good.

Characteristics:

This GMAW wire is for Rm 500MPa level carbon steel with shield gas of CO2 or M21. Small spatter, beautiful appearance, high deposition efficiency and small weld metal porosity sensibility.

All positions is suitable.

Attention:

- The rust, oil, water and other impurities of the weld area must be removed before welding.

- The mechanical properties of all weld metal be decided by heat input, normally the small heat input will better than larger one.

Production Process:

Wire release: after the prepared raw materials are released, they are mechanically peeled off;

Rust removal: The raw materials that have been peeled off are subjected to abrasive belt treatment (during the treatment process, dust removal is carried out with a cloth bag), to remove the oxide skin on the surface of the welding wire and the remaining impurities on the surface of the welding wire, and obtain the raw material of the welding wire for derusting;

Wire drawing: the wire drawing process is performed on the raw materials of the welding wire after derusting to obtain the semi-finished product of the welding wire, and then the semi-finished product is subjected to wire-drawing and fine-drawing treatment;

High-speed copper plating: activate and copper-plate the semi-finished products that have been drawn;

Polishing: Polish and take up the copper-plated welding wire;

Finally, the copper-plated welding wire is unwound, layered, packaged and put into storage.

This process uses the abrasive belt to derust and clean the surface of the welding wire raw material. Compared with the existing technology, the amount of acid is reduced, and the welding wire does not need to be cleaned with alkali, so that the impurities on the surface of the welding wire can be effectively removed by the abrasive belt derusting, and the acid is reduced. The amount of lye is low, energy saving and environmental protection.

Chemical Composition:

|

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

Cu |

|

0.06-0.15 |

1.4-1.85 |

0.8-1.15 |

≤0.025 |

≤0.025 |

≤0.15 |

≤0.15 |

≤0.15 |

≤0.03 |

≤0.5 |

Mechanical Property:

|

AWS |

Tensile Strength Rm |

Yield Strength Rel/Rp0.2 |

A |

KV2 (-30C)/J |

|

MPa |

MPa |

% |

0 degree/J |

|

|

ER70S-6 |

≥500 |

≥420 |

≥22 |

≥27 |

Specification & Package

- 25kg, 50kg, 150kg, 200kg, 350kg, 500kg, 1000kg all available, transverse wind without core, Vaccum packing

- 250kg, 500KGS steel spool; Submerged-arc welding wire can be packed as your requirements.

Specifications: EL9, EM12, EH14, EM13K, EL12,EB2 etc. 1.6mm, 2.0mm,2.4mm,3.2mm,4.0mm,5.0mm

Color print box is available.

OEM/ODM Package Available:

we also can do different kgs package, different brand print.

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

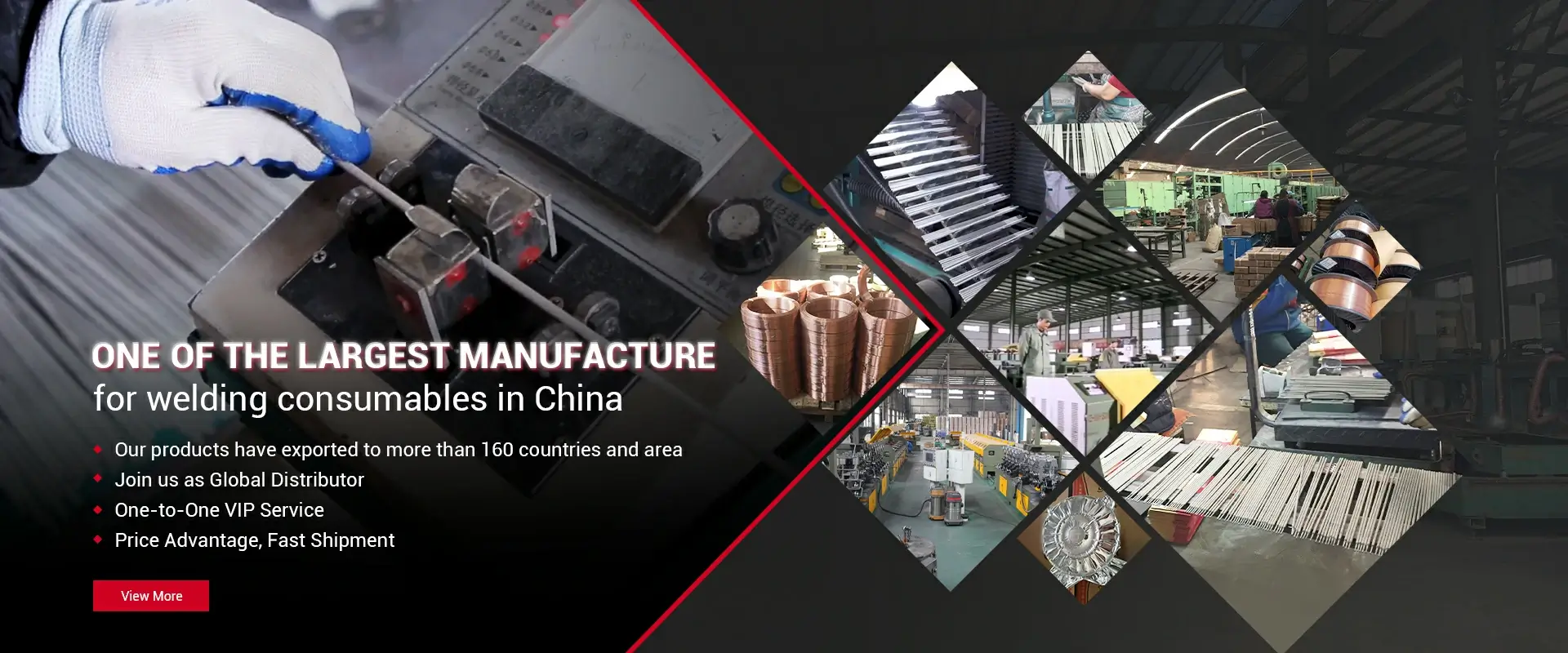

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry