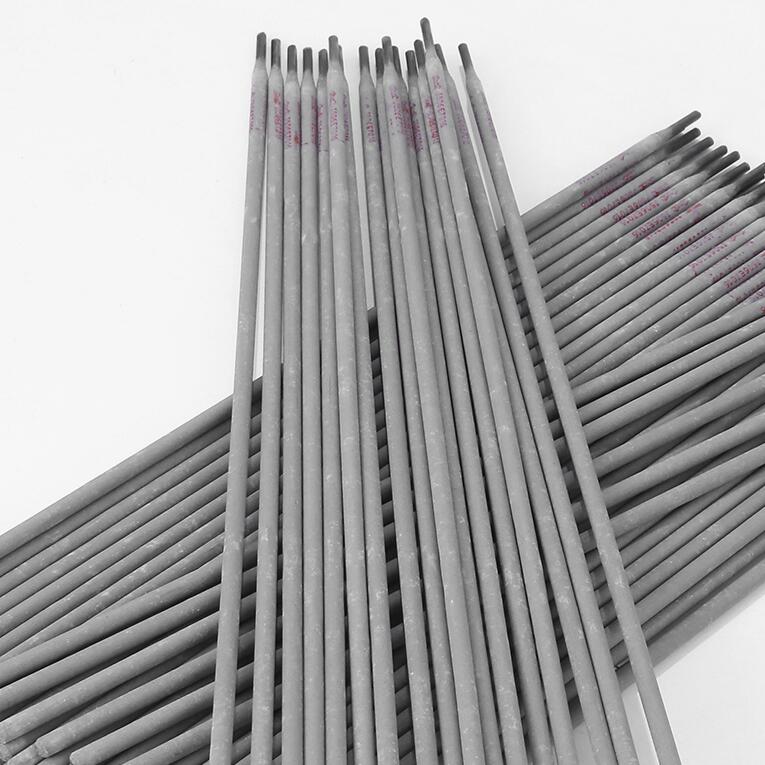

E7016 WELDING RODS

E7016 welding rods, also known as 7016 welding rods, offer several advantages that make them an ideal choice for various welding applications. These low-hydrogen electrodes are specifically designed to provide exceptional arc stability and produce high-quality welds with minimal spatter, making them perfect for both professional and amateur welders. The E7016 welding rod is well-suited for vertical and overhead welding positions, providing excellent control and ease of use in challenging welding scenarios. As a versatile welding electrode 7016, it is commonly used for welding mild and low-alloy steels, delivering strong and durable welds that are resistant to cracking. Additionally, the 7016 welding rod exhibits superior performance in environments where weld quality and reliability are critical, such as pipeline welding, structural steel fabrication, and shipbuilding.

One of the key benefits of using E7016 welding rods is their ability to produce clean, consistent welds with a smooth bead appearance, reducing the need for post-weld cleanup and improving overall productivity. The low hydrogen content in the electrode 7016 helps to prevent hydrogen-induced cracking, which is particularly important when welding thicker materials or working in cold conditions. The E7016 welding rod also offers a high deposition rate, allowing for faster welding speeds and increased efficiency. Furthermore, the 7016 electrode’s ability to maintain a stable arc even at low amperages makes it a preferred choice for welders looking to achieve precise, controlled welds on a variety of materials and thicknesses. With its excellent mechanical properties, ease of use, and versatility, the E7016 welding rod is a reliable choice for welders seeking to enhance their skills and achieve superior welding results in a range of applications. Whether you are welding pipes, structures, or heavy machinery, the E7016 welding electrode ensures a strong, dependable weld every time.

-

J506 ( E7016 ) is a low hydrogen potassium type basic coated electrode. Both AC and DC can be used and can be all-position welding.

J506 ( E7016 ) is a low hydrogen potassium type basic coated electrode. Both AC and DC can be used and can be all-position welding. -

J506 ( E7016 ) is a low hydrogen potassium type basic coated electrode. The full name of 7016 electrode is E7016 electrode, that is, low hydrogen potassium carbon steel electrode,

J506 ( E7016 ) is a low hydrogen potassium type basic coated electrode. The full name of 7016 electrode is E7016 electrode, that is, low hydrogen potassium carbon steel electrode, -

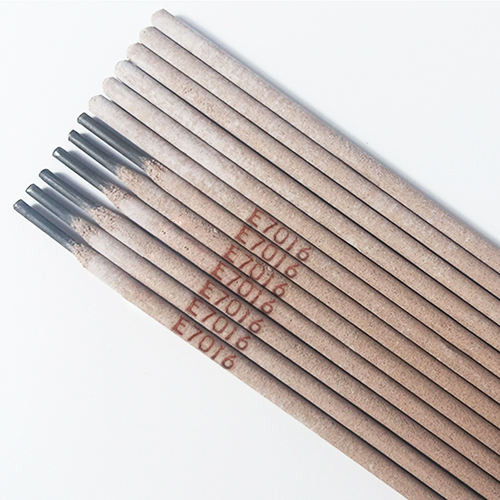

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A -

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A -

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A

J506 (J48.56) GB/T 5117 E5016 AWS A5.1 E7016 ISO 2560-B-E 49 16 A

E7016 Electrode Meaning

The designation “E7016” is a classification used in the American Welding Society (AWS) specifications that provide vital information about the electrode's characteristics. The “E” stands for electrode, while the “70” signifies the minimum tensile strength of 70,000 psi, crucial for structural integrity. The “1” indicates that it can be used in all-position welding, meaning welders can work on horizontal, vertical, overhead, and flat surfaces. Lastly, the “6” denotes the type of coating, which is made from a low hydrogen flux that helps minimize the risk of cracking and increases the electrode's versatility.

E7016 welding rods are particularly revered for their stability and ease of use. They are considered versatile electrodes, suitable for welding mild steel in various industrial applications, such as construction and automotive repair. Their low hydrogen content significantly reduces the risk of hydrogen-induced cracking, making them ideal for critical applications requiring high-quality welds.

For professionals and hobbyists alike, understanding the meaning of E7016 electrodes is fundamental. Whether you are welding structural components or working on delicate projects, using E7016 welding rods can ensure you achieve the desired results with strength and durability. The next time you reach for an electrode, consider the E7016 – a smart choice for any welding application.

E7016 Welding Rod Uses

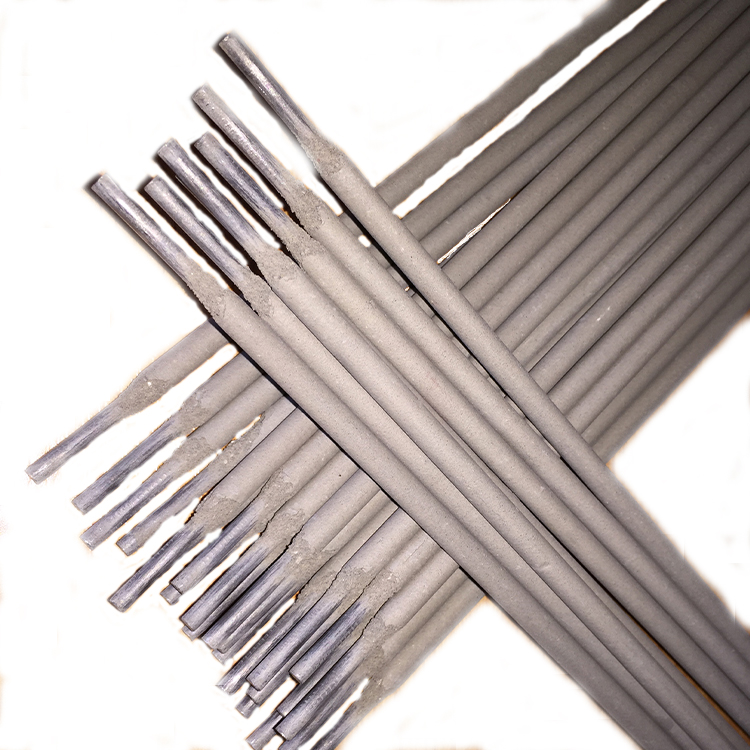

1. Structural Welding: One of the primary uses of E7016 welding rods is in structural applications. These rods are ideal for welding steel structures, ensuring strong and resilient joints that can withstand significant stresses.

2. Pipe Welding: The low hydrogen properties of E7016 rods reduce the risk of hydrogen-induced cracking, making them perfect for pipe welding, especially in critical applications like oil and gas pipelines.

3. Fabrication and Repair Work: Due to their high deposition rates and excellent bead appearance, E7016 welding rods are widely used for fabrication and repair work, delivering strong welds that can endure harsh conditions.

4. Heavy Equipment Maintenance: Welders often choose E7016 rods for repairing heavy machinery, as they can effectively join thick metal plates and provide durable welds necessary for high-performance equipment.

E7016 Vs E7018

E7016 Welding Rods: Advantages and Applications

E7016 welding rods are known for their excellent performance in portable welding setups. These electrodes are characterized by their iron powder coating, which provides improved deposition efficiency. Additionally, the E7016 rods are particularly effective for welding in positions that might be challenging, thanks to their stable arc and smoother bead appearance. This makes them a popular choice for fabricators and contractors working in numerous industries, including construction and heavy manufacturing.

E7018 Welding Rods: Strength and Versatility

On the other hand, E7018 welding rods are highly regarded for their strength and versatility. These electrodes are low hydrogen rods, designed to minimize the risk of cracking in high-strength materials. E7018 rods produce welds with excellent mechanical properties, making them ideal for critical applications like structural steel, pressure vessels, and heavy machinery. While they may require more skill to use effectively, the results speak for themselves, providing strong and durable welds.

E7016 Welding Rod Specifications

High-Strength Performance: The E7016 Welding Rod boasts a minimum tensile strength of 70,000 psi and yield strength of 58,000 psi, ensuring robust welds perfect for demanding applications.

All-Position Versatility: Designed for all-position welding, the E7016 Welding Rod allows for flat, horizontal, vertical, and overhead work, making it an ideal choice for various welding projects.

Low-Hydrogen Coating: With its low-hydrogen flux coating, this welding rod provides excellent arc stability and minimizes the risk of hydrogen-induced cracking, ensuring the integrity of your welds.

Durable Mechanical Properties: The E7016 Welding Rod features an elongation of at least 22% in 8 inches and good impact toughness across different temperatures, making it suitable for a variety of environmental conditions.

Reliable After-Sales Support: We stand behind the quality of our welding electrodes for sale, offering dedicated customer service and support to assist you with any inquiries or issues post-purchase.