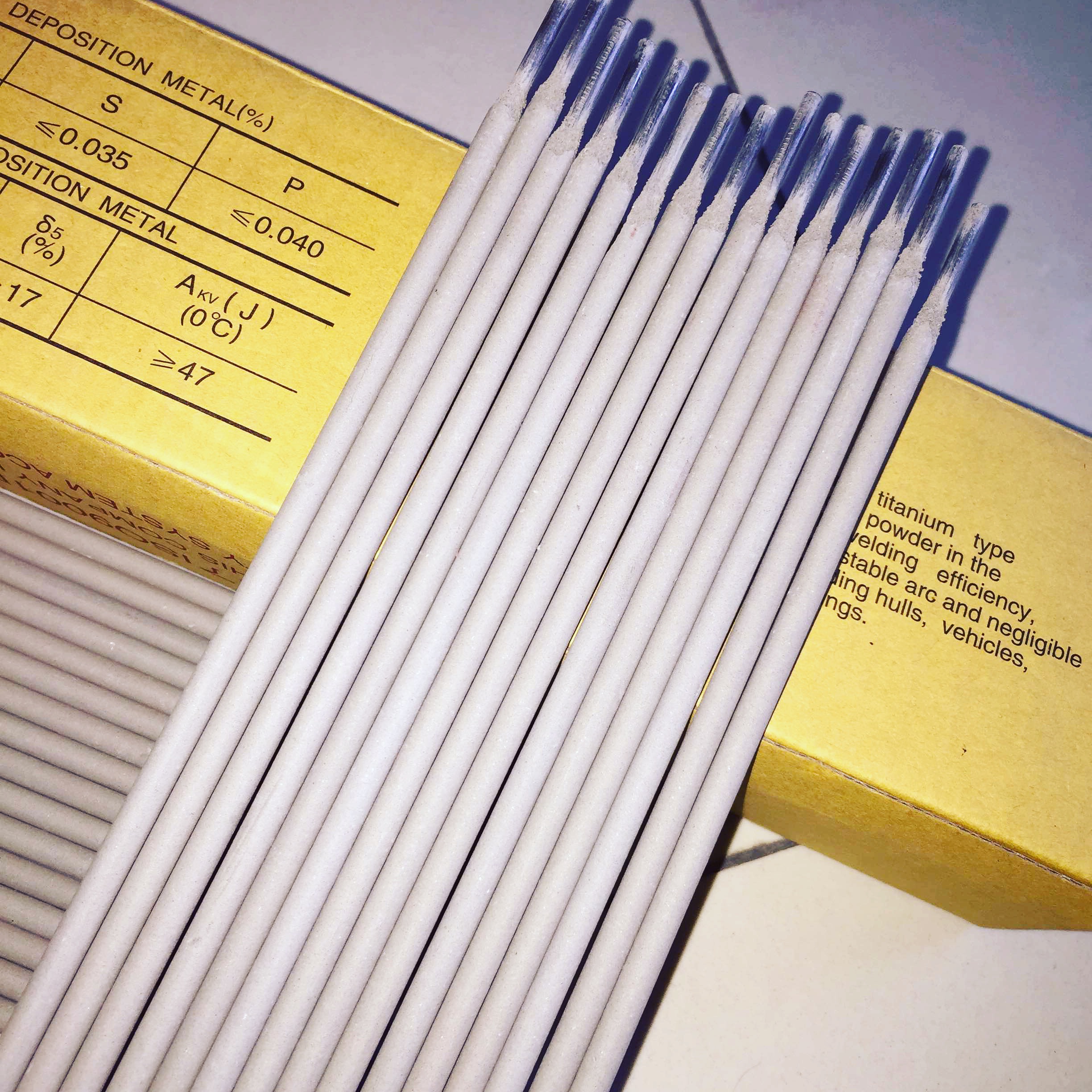

ARC Welding Electrodes AWS E7024

The E7024 welding rod, also known as an iron powder electrode, offers numerous advantages that make it a popular choice in the field of arc welding. One of the primary benefits of using the E7024 welding rod is its excellent deposition rate, which is significantly higher than many other types of electrodes. This high deposition rate is due to the iron powder in the flux coating, which allows for more metal to be deposited per pass, reducing the number of passes required and ultimately enhancing productivity. Additionally, the E7024 electrode is renowned for its smooth and stable arc, which facilitates easy handling and control, especially for less experienced welders. The stable arc also produces minimal spatter, leading to cleaner welds and reducing post-weld cleanup time. Another significant advantage is its ability to create strong and durable welds with good mechanical properties, such as high tensile strength and ductility, making it suitable for applications involving low to medium carbon steel. Moreover, E7024 welding rods are designed for flat and horizontal fillet welds, making them ideal for fabricating and assembling heavy equipment, structures, and tanks. Their ability to produce a smooth, bead-like appearance with a flat, uniform contour contributes to the overall aesthetic and quality of the finished weld. The ease of slag removal further adds to the convenience, as the slag peels away effortlessly, reducing the risk of inclusions and ensuring a cleaner weld surface. Additionally, these rods are versatile in their applications, being well-suited for both AC and DC power sources, providing flexibility to welders based on the available equipment. Overall, the E7024 welding rod's combination of high efficiency, ease of use, and superior weld quality makes it a highly advantageous choice for a variety of welding tasks.

-

Arc welding electrodes AWS E7024 (J501Fe18 / GB/T E5024) Rutile iron powder electrode for high efficiency.

E7024 Welding Rod Uses

The E7024 welding rod is a specialized consumable designed for efficient and high-quality welding, primarily in the field of heavy fabrication and industrial welding projects. With its unique properties, the E7024 welding rod offers a range of advantages that make it a preferred choice among welders in various applications.

One of the primary uses of the E7024 welding rod is in flat and horizontal welding positions. Its design allows for excellent bead control, ensuring that welds are smooth and visually appealing. This is particularly important in industries where aesthetics and structural integrity are crucial, such as construction and manufacturing.

The E7024 welding rod is known for its high deposition rates, which significantly increase productivity. This characteristic makes it an excellent choice for welding thicker materials and larger structures, such as bridges, shipbuilding, and heavy machinery repairs. The ability to lay down weld quickly without compromising on quality is a major selling point for this rod.

Another important use of the E7024 welding rod is its versatility across various metals, including mild steel and some low-alloy steel. This versatility means that welders can use the E7024 rod in a wide range of projects, from automotive assembly to intricate pipeline work. The rod’s ability to produce strong, ductile, and crack-resistant welds makes it an invaluable tool in any welder’s arsenal.

Additionally, the E7024 welding rod shows excellent resistance to porosity and undercutting, which are common problems in welding. This reliability makes it an ideal choice for professionals who require consistent results, particularly in demanding environments where mistakes can be costly.

E7024 Electrode Specification

This versatile premium welding electrode is typically classified as an all-position welding rod, allowing you to wield it in various orientations without compromising on quality. The E7024 boasts a minimum tensile strength of 70,000 psi, which is scientifically formulated to ensure that your welds can withstand significant stress and strain.

But that’s not all! This welding rod operates on DC+ polarity, which means you’ll have smoother arcs and reduced spatter. If you’re looking for seamless performance, the E7024 welding rod will not disappoint. It also features an iron powder in the flux coating, which increases deposition and helps you finish your work more efficiently—who doesn’t love saving time while maintaining quality?

When choosing the right diameter for your project, you’ll typically find E7024 rods available in a range from 1/16” to 1/4”. No matter the size of your endeavor, there’s an E7024 welding rod that can meet your needs.

In conclusion, if you’re seeking a welding rod that merges durability, efficiency, and versatility, look no further than the E7024 welding rod. With high tensile strength and the added benefit of reduced spatter, it’s the perfect partner for all your welding projects. So gear up, grab some E7024 welding rods, and get ready to bring your welding game to new heights!

E7024 electrode Classification

The "E" in E7024 stands for "electrode," indicating that it’s designed for welding purposes. The numbers following it signify essential characteristics. The "70" denotes the minimum tensile strength of the weld metal, measured in thousands of psi. In simple terms, it means that the E7024 welding rod can handle heavy loads, making it ideal for structural welds in bridges and buildings. Who wouldn’t want a sturdy weld that can withstand the test of time?

But wait, there’s more! The “24” at the end indicates the type of coating on the electrode. E7024 rods come with a high iron powder content, which allows for an increased deposition rate. In less technical terms, they allow you to lay down more metal faster, making your welding project quicker and more efficient. It's like having a turbocharger for your welding machine!

Welders often rave about the E7024 welding rod’s ability to produce smooth, flat welds with minimal cleanup – a time-saver, indeed! This feature makes it an excellent choice for fabricators and construction workers who demand quality without the fuss.

In conclusion, if you want strength, efficiency, and ease of use, the E7024 welding rod is definitely worth a shot. With its high tensile strength and impressive deposition rates, it’s no wonder that this electrode has earned its stripes in the welding industry. So the next time you’re gearing up for a welding project, remember that E7024 might just be the trusty sidekick you didn’t know you needed!