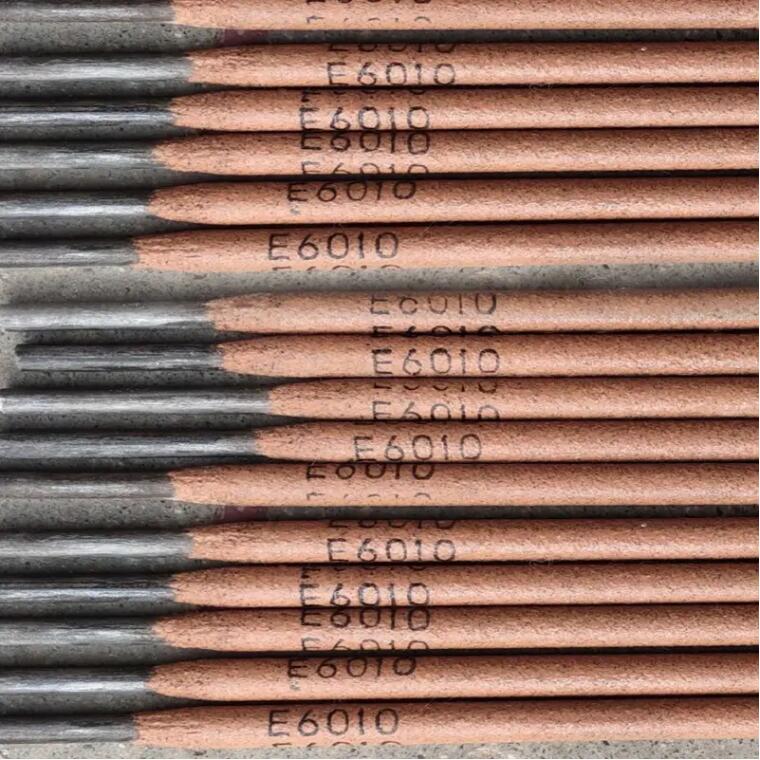

E6010 WELDING RODS

The E6010 welding rods for sale offer numerous advantages for welders seeking a reliable and versatile solution for their projects. Known for their deep penetration and robust performance, the 6010 welding rod, including the popular 6010 1/8 welding rod, is ideal for various applications ranging from pipeline welding to general maintenance. The e6010 electrode excels in all positions, making it a versatile choice for complex welding tasks. With options like the 6010 welding rod 1/8 and bulk purchases such as 50 lbs of 6010 welding rod, welders can ensure they have the right amount of high-quality material for large-scale projects. Additionally, the 6010 red welding rod variant provides the same reliable performance with an added visual distinction. Given the competitive 6010 welding rod price, these electrodes offer exceptional value, making them a cost-effective choice for professional and hobbyist welders alike.

-

Pipeline welding rod E6010 cellulose welding rod Description: E6010 is a high-cellulose sodium-coated electrode for direct current.

Pipeline welding rod E6010 cellulose welding rod Description: E6010 is a high-cellulose sodium-coated electrode for direct current. -

E6010 is a high cellulose sodium type covered vertical downward electrode.

E6010 is a high cellulose sodium type covered vertical downward electrode. -

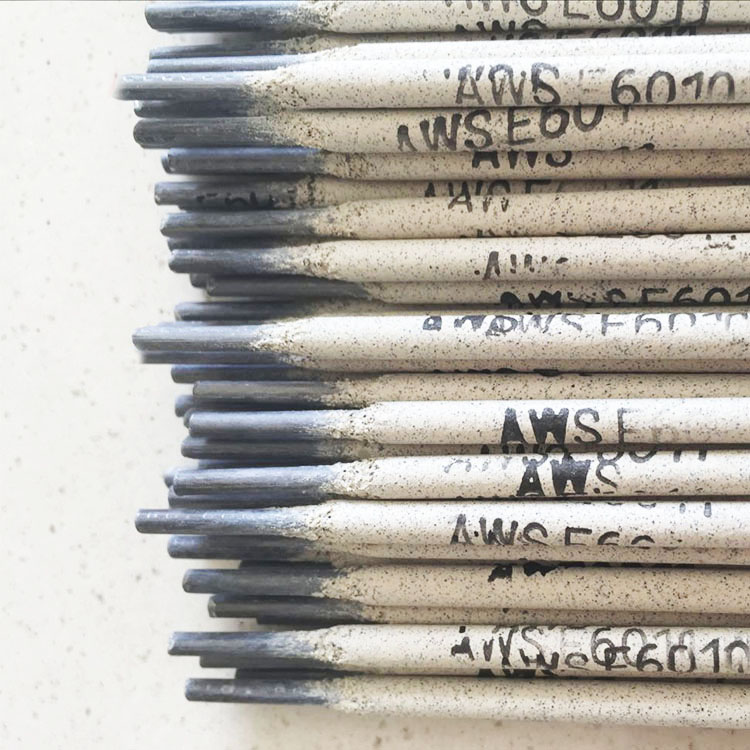

Model: AWS E6010 Our factory welding electrodes E6010 output is more than 80000 metric tons, AWS E6010 is suitable for butt welding,

Model: AWS E6010 Our factory welding electrodes E6010 output is more than 80000 metric tons, AWS E6010 is suitable for butt welding, -

Type: AWS E6010 AWS E6010 is a high cellulose sodium type carbon steel welding electrode for vertical-down welding .

Type: AWS E6010 AWS E6010 is a high cellulose sodium type carbon steel welding electrode for vertical-down welding . -

E6010 Welding electrode belongs to PM PRO-60. This electrode is specially designed for the pipeline industry.

E6010 Welding electrode belongs to PM PRO-60. This electrode is specially designed for the pipeline industry.

What Are 6010 Welding Rods Used For

- 1. Pipeline Welding:

One of the primary uses of E6010 welding rods is in pipeline welding. These electrodes are known for their ability to create strong and durable welds, making them ideal for joining pipes in industries such as oil and gas, water distribution, and construction. The high penetration and fast-freezing slag of E6010 electrodes make them well-suited for welding pipes in challenging and demanding environments.

2. Structural Welding:

E6010 welding rods are also commonly used in structural welding projects. Whether it's building bridges, skyscrapers, or other large structures, these electrodes excel in producing high-quality welds with excellent penetration and fusion characteristics. Structural welders appreciate the ease of use and consistent performance of E6010 electrodes in tackling complex welding tasks.

3. Fabrication and Repair Work:

For fabricators and repair technicians, E6010 welding rods are indispensable tools. These electrodes can be used to weld a wide range of materials, including mild steel, carbon steel, and low-alloy steel, making them versatile options for various fabrication and repair projects. Whether it's fixing farm equipment, automotive parts, or machinery, E6010 electrodes offer the strength and reliability needed to get the job done.

4. Maintenance and Shutdown Projects:

In industrial settings, maintenance and shutdown projects often require welding solutions that can deliver fast and efficient results. E6010 welding rods are commonly used in these scenarios due to their ability to produce deep, uniform penetration welds with minimal spatter. Whether it's repairing equipment, restoring infrastructure, or conducting plant maintenance, E6010 electrodes are trusted for their performance and reliability.

Welding Electrode E6010 Specification

Composition and Coating

Coating Type: Cellulose sodium. This type of coating produces a forceful arc with deep penetration capabilities, making it suitable for welding through contaminants such as rust, oil, and paint.

Core: The core wire is typically made of mild steel.

Mechanical Properties

Tensile Strength: 60,000 psi (pounds per square inch). This high tensile strength ensures strong and durable welds.

Yield Strength: Approximately 48,000 psi. This indicates the stress at which the material will deform permanently.

Elongation: About 22%. This measures the ductility of the weld metal, indicating its ability to stretch before breaking.

Electrical Characteristics

Current Type: DC+ (Direct Current Electrode Positive). The E6010 is specifically designed to work with direct current, electrode positive, ensuring a stable arc and optimal penetration.

Amperage Range:

For a 1/8 inch (3.2 mm) rod: 75-125 amps.

The exact amperage can vary based on the electrode diameter and the specific application.

Usability

Welding Positions: All positions (flat, horizontal, vertical, and overhead). The E6010's versatility in all positions makes it suitable for a wide range of welding tasks.

Penetration: Deep. This deep penetration capability is ideal for welding thick materials and ensuring the weld is strong and secure even when dealing with impurities on the material's surface.

Operational Features

Arc Characteristics: The E6010 produces a forceful, high-digging arc that helps in penetrating deep into the base material. This feature is particularly useful for cleaning the base material while welding.

Slag: Leaves a thin, easily removable slag, which simplifies post-weld cleaning and enhances productivity.

Bead Appearance: While the E6010 offers excellent penetration, the resulting weld bead may be less smooth and aesthetically pleasing compared to low-hydrogen electrodes like the E7018. This is a trade-off for its penetration capabilities.

Sizes and Packaging

Common Sizes:

1/16 inch (1.6 mm)

5/64 inch (2.0 mm)

3/32 inch (2.4 mm)

1/8 inch (3.2 mm)

5/32 inch (4.0 mm)

Packaging: Typically available in various package sizes, including bulk options such as 50 lbs boxes. The packaging can vary depending on the manufacturer and the supplier.

Key Advantages

Deep Penetration: Ideal for welding through rust, oil, paint, and other surface contaminants.

Versatility: Suitable for all-position welding, making it a versatile choice for various applications.

Strong Arc Force: Helps in cleaning the base material during welding, which is especially useful in maintenance and repair work.

Ease of Use: The E6010 is relatively easy to use, although it requires some skill to control the forceful arc effectively.

Typical Applications

Pipeline Welding: Widely used in the pipeline industry due to its ability to penetrate deeply and weld through contaminants.

Root Passes: Often used for root passes in multi-pass welds to ensure a strong foundation for subsequent layers.

Maintenance and Repair: Suitable for welding in various conditions, including dirty or rusty surfaces.

Construction and Structural Work: Used in construction projects for its versatility and strong welds.

Shipbuilding: Employed in shipbuilding for its deep penetration and ability to handle surface contaminants.