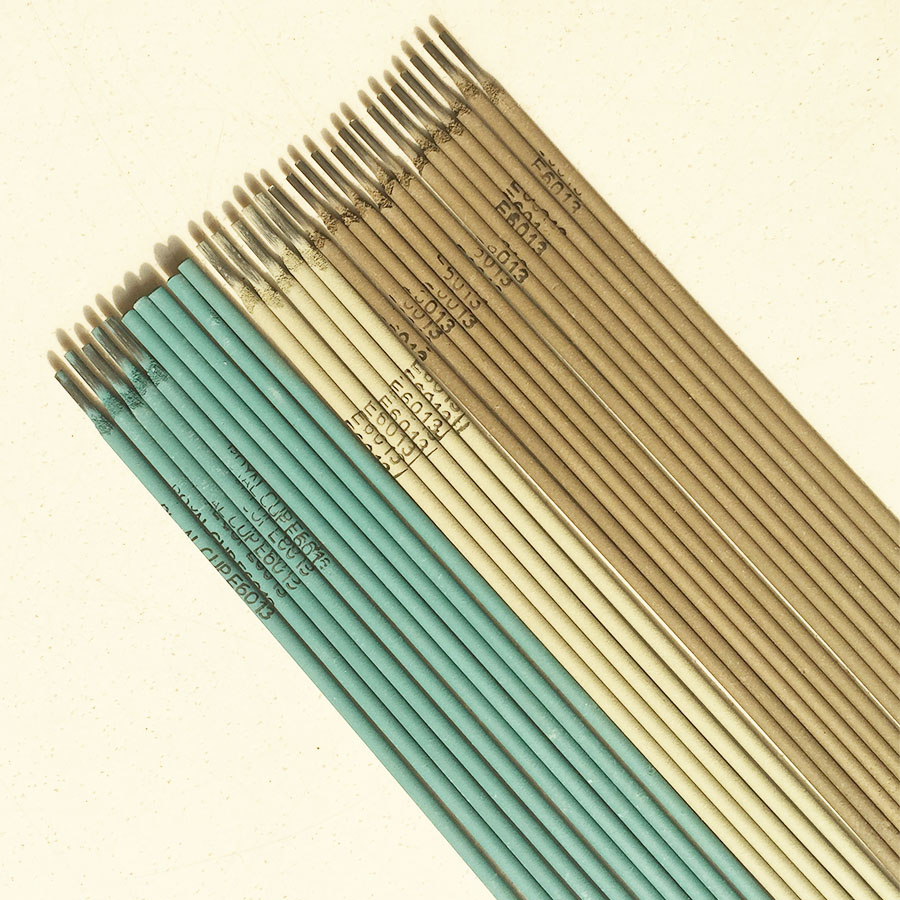

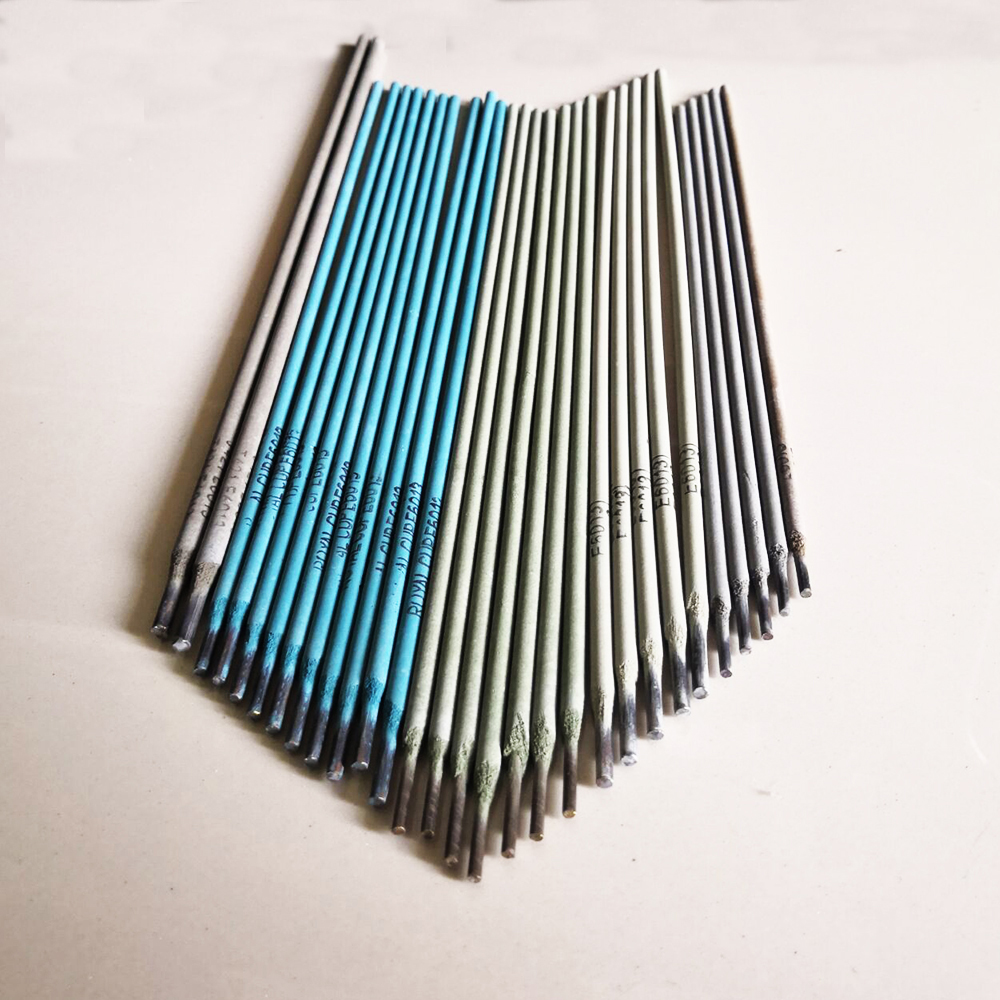

E6013 WELDING RODS

Are you interested in purchasing the versatile 6013 welding rod? This type of welding rod, also known as e6013 welding rods or e6013 electrodes, offers numerous advantages that make it a top choice for welders. One key benefit is its ease of use, making it perfect for welders of all skill levels to achieve excellent results thanks to its smooth arc action and minimal spatter. Additionally, the 6013 welding rod is highly versatile, allowing for welding in various positions such as flat, horizontal, vertical, and overhead, providing flexibility for a wide range of projects. Its compatibility with different metals further enhances its utility for a variety of applications. With its consistent performance and reliable results, the 6013 welding rod is a dependable option for producing high-quality welds efficiently.

-

E6013 is a Carbon Steel welding electrode, it is suitable to work in all positions with excellent welding technological properties, stable arc less splash, shaped good appearance, easy for removal of slag layer, easy for striking arc and restriking arc.

E6013 is a Carbon Steel welding electrode, it is suitable to work in all positions with excellent welding technological properties, stable arc less splash, shaped good appearance, easy for removal of slag layer, easy for striking arc and restriking arc. -

Our AWS E6013 is one type of Carbon Steel welding electrode, 422 electrode is a kind of welding tool, which is an acid electrode, coating titanium calcium type, and the corresponding international standard electrode model is E4303.

Our AWS E6013 is one type of Carbon Steel welding electrode, 422 electrode is a kind of welding tool, which is an acid electrode, coating titanium calcium type, and the corresponding international standard electrode model is E4303. -

Our AWS E6013 is one type of Carbon Steel welding electrode, it is suitable to work in all positions with excellent welding technological properties, The welding rod grade of AWS standard is equivalent to my country's national standard model J421.

Our AWS E6013 is one type of Carbon Steel welding electrode, it is suitable to work in all positions with excellent welding technological properties, The welding rod grade of AWS standard is equivalent to my country's national standard model J421. -

Standard: AWS E6013/GB E4303 Rutile e6013 is the high quality electrode grade, which refers to the structural steel electrode. It has an acidic coating, including high-titanium potassium coating, and its diameter is generally 3.0-5.0mm.

Standard: AWS E6013/GB E4303 Rutile e6013 is the high quality electrode grade, which refers to the structural steel electrode. It has an acidic coating, including high-titanium potassium coating, and its diameter is generally 3.0-5.0mm. -

The diameter of the welding electrode does not include the diameter of the coating. The 2.0mm welding electrode refers to the iron core diameter of the electrode is 2.0mm. There is no fixed standard for how thin the welding rods can weld with a diameter of 2.0mm.

The diameter of the welding electrode does not include the diameter of the coating. The 2.0mm welding electrode refers to the iron core diameter of the electrode is 2.0mm. There is no fixed standard for how thin the welding rods can weld with a diameter of 2.0mm.

6013 Welding Rod Use

When it comes to welding, one of the most versatile and widely used electrodes is the 6013 welding rod. This electrode is known for its ease of use, excellent weld bead appearance, and smooth arc characteristics.

One of the primary uses of the 6013 welding rod is in general welding applications. It is suitable for welding mild steel, galvanized steel, and some low alloy steels. The 6013 electrode can produce smooth, clean welds with minimal spatter, making it ideal for both beginner and experienced welders.

Additionally, the 6013 welding rod is commonly used for maintenance and repair welding. Whether you are working on farm equipment, automotive parts, or structural components, the 6013 electrode can provide strong and reliable welds. Its all-position welding capability further enhances its versatility, allowing welders to tackle various projects with ease.

Another key benefit of the 6013 welding rod is its ability to strike and maintain a stable arc, even on less-than-ideal surfaces. This makes it a valuable tool for field welding, where conditions may be less controlled than in a workshop setting. The 6013 electrode performs well on dirty, rusted, or painted surfaces, ensuring consistent and high-quality welds.

What's the Difference Between 6011 and 6013 Welding

Rods

When it comes to welding rods, the debate between 6011 and 6013 is as heated as a molten metal pool. So, what's the deal with these two popular welding rods? Let's spark up this debate and shed some light on the key differences between 6011 and 6013 welding rods.

First off, let's talk about 6011 welding rods. These bad boys are known for their versatility and strength. If you're looking to weld on dirty, rusted, or painted surfaces, 6011 rods are your best bet. They have a deep penetration ability, making them ideal for heavy-duty welding projects. Think of 6011 rods as the tough guy in the welding world, never backing down from a challenge.

On the other hand, we have 6013 welding rods. These rods are more like the smooth talkers of the welding scene. They are easy to use, produce minimal spatter, and are great for thin metal sheets. If you're a beginner or working on light to medium-duty projects, 6013 rods are the way to go. They provide a clean and neat weld, perfect for those intricate jobs that require finesse.

Now, let's address the elephant in the room – the differences between 6011 and 6013 welding rods. While both rods can be used in all welding positions, the key distinction lies in their coating and welding properties. 6011 rods have a cellulose potassium coating that produces a deep, penetrating arc, making them ideal for welding thick materials. On the flip side, 6013 rods have a rutile coating that creates a smooth, easy-to-control arc, perfect for beginners or those working on thin metals.

In conclusion, the choice between 6011 and 6013 welding rods ultimately depends on the nature of your welding project. If you're tackling heavy-duty tasks and need deep penetration, go for the tough guy – 6011 rods. On the other hand, if you're a newbie or working on delicate projects, opt for the smooth talker – 6013 rods. Remember, each welding rod has its unique strengths, so choose wisely based on your specific welding needs.

So, next time you're at the welding station faced with the age-old question of 6011 vs. 6013, you'll know exactly what sets these two rods apart. Happy welding!