Hebei Yujinhong’s Great Master Story

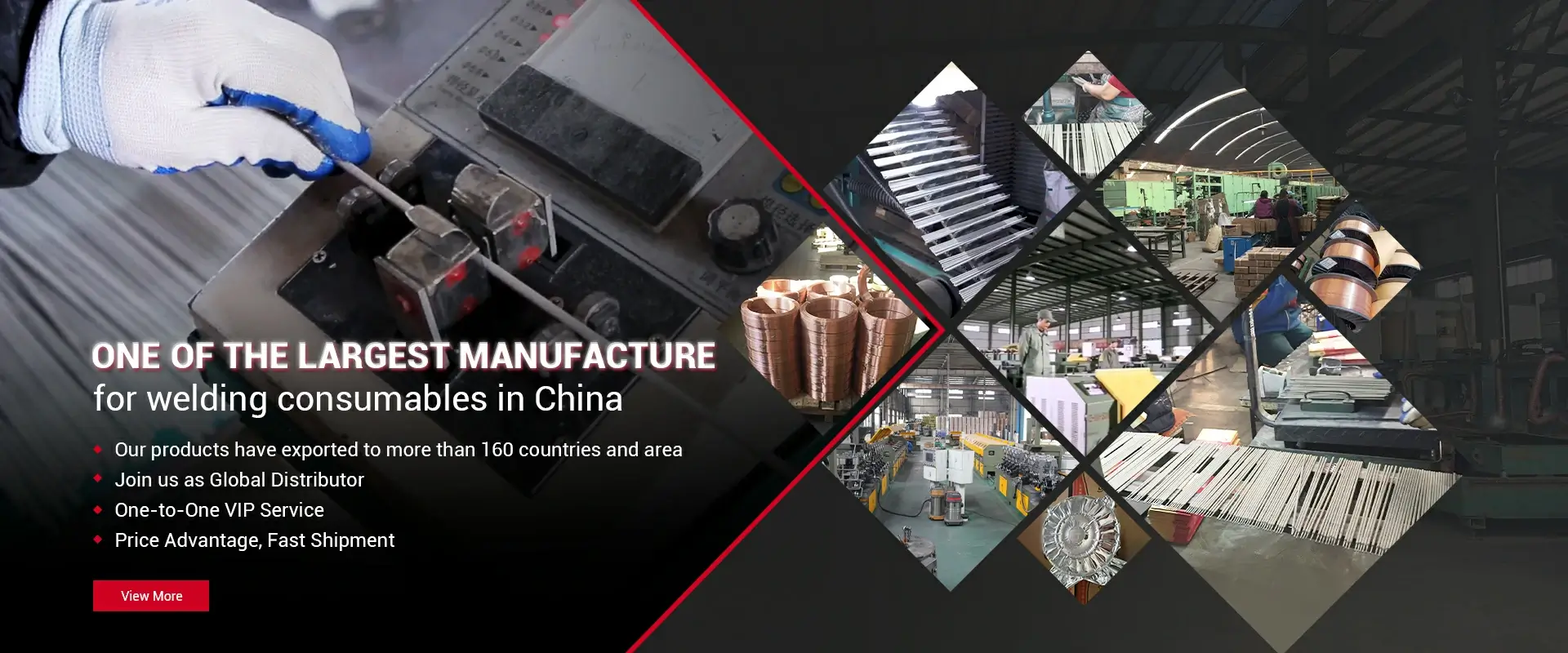

Since 1996, hebei yujinhong technology co., ltd has taken root in Shijiazhuang, a renowned city in northern China, with a mission that guides every step: “Make Great Master Forever.” We don’t just see ourselves as a welding electrode manufacturer or welding wire factory—we strive to create “masterpieces” in the welding consumables industry, a vision that gave birth to our “GREAT MASTER” brand when we registered it in 2010. For us, a “masterpiece” isn’t just a product; it’s something that stands the test of time, breaks old limits, and delivers lasting value—qualities we infuse into every welding electrode and wire we make. From a small workshop focused on local demand to a global partner trusted by wholesalers across North America, Europe, South America, and Australia, our journey has been driven by one belief: every welding point should be unbreakable, and every client should feel confident in the products they use. Backed by a 1,000,000-square-meter factory, 520 skilled team members, and certifications from global authorities like ABS, BV, CCS, and CE, we uphold the “GREAT MASTER” spirit in every batch, ensuring our wholesale partners get products that align with their long-term goals of reliability and client satisfaction.

Why Wholesalers Choose This Welding Electrode Manufacturer

For wholesalers, the difference between a good supplier and a great one lies in shared values—and our welding electrode manufacturer and welding wire factory’s “Make GREAT MASTER Forever” idea resonates deeply with those seeking lasting partnerships. Unlike ordinary welding electrode companies that cut corners to meet short-term demands, we invest heavily in research and development to improve product quality, just as we did when we first set out to build the “GREAT MASTER” brand. This commitment means every welding electrode we produce undergoes rigorous checks: from selecting high-purity raw materials to testing mechanical properties and arc stability, we leave no room for inconsistency. As a wholesaler, you’ll benefit from this rigor—fewer client complaints, less rework, and a reputation as a supplier that delivers “masterpiece-level” products. We also offer flexible bulk terms: competitive pricing to protect your profit margins, customizable packaging (with your brand or ours), and a logistics network that ensures on-time delivery, so you can keep your inventory steady and your clients happy. Our team doesn’t just stop at supply; we share your goal of growing your business, and we’re here to support you every step of the way.

Our Welding Wire Factory’s “GREAT MASTER” Quality Promise

Our welding wire factory doesn’t just produce wire—we craft products that live up to the “GREAT MASTER” name, a promise that starts with how we define quality. For us, quality isn’t just meeting standards; it’s exceeding expectations, a mindset we’ve held since we expanded our production base in 2006 to achieve refined manufacturing. Every spool of welding wire from our welding wire factory is made with precision: advanced wire-drawing machines ensure uniform diameter, surface treatments remove oxides that cause defects, and every batch is tested for tensile strength and compatibility with different welding processes. This attention to detail means your clients—whether in shipbuilding, machinery manufacturing, or structural steel work—get wire that feeds smoothly, melts evenly, and creates welds that hold up under pressure. We also listen to user feedback, just as we did when we first launched “GREAT MASTER”: if a client suggests a tweak to improve performance, our R&D team acts on it, ensuring our wire stays ahead of industry needs. For you as a wholesaler, this means offering products that your clients will ask for by name, turning one-time orders into long-term relationships.

How This Welding Electrode Company Supports Wholesale Growth

We know that as a welding electrode company, our success is tied to yours—and that’s why we go beyond supplying products to support your growth. When you partner with us, you’re not just getting a welding rod manufacturing company’s goods; you’re getting access to tools that help you sell more. We provide tailored marketing materials for “GREAT MASTER” products, including brochures that highlight our brand story and case studies of how our electrodes solved clients’ problems—materials you can share directly with your customers to build trust. If your clients want to test our products before placing a bulk order, we offer free samples (you only cover shipping), making it easier for you to close deals. We also understand that wholesalers need flexibility: you can adjust order quantities based on your inventory forecasts, and we offer long-term supply agreements to lock in pricing, protecting you from market fluctuations. Our team of welding experts even provides training for your staff, teaching them how to explain the “GREAT MASTER” difference to clients—so your team feels confident and your clients feel informed.

Welding Rod Manufacturing Company’s Innovation for Timeless Value

As a welding rod manufacturing company, we believe that “Make GREAT MASTER Forever” means staying innovative, not just repeating past successes. Since 2009, when we expanded our overseas business, we’ve invested in new technologies to improve our rods: from developing flux coatings that reduce spatter to creating rods that work in harsh outdoor conditions, we’re always looking for ways to add value. This innovation isn’t just for show—it solves real problems for your clients. For example, our low-hydrogen welding rods prevent cold cracking in thick steel, a common issue in heavy industry, while our all-position rods let welders work efficiently in tight spaces. We also prioritize sustainability, a key part of modern “masterpiece” thinking: our production processes reduce waste, and we source raw materials from certified suppliers who share our commitment to the environment. For you as a wholesaler, this innovation means you can offer products that keep up with your clients’ evolving needs—whether they’re adopting new welding techniques or focusing on eco-friendly practices—helping you stay ahead of other suppliers.

Hebei Yujinhong FAQ

Does your welding electrode manufacturer offer brand support for wholesalers’ local marketing?

Yes, our welding electrode manufacturer provides customized brand support, including co-branded packaging (with your logo and “GREAT MASTER”), localized marketing materials, and even social media content that highlights your partnership. This helps you reinforce your brand identity while leveraging our “GREAT MASTER” reputation.

How does your welding wire factory ensure consistency in bulk orders for our clients?

Our welding wire factory uses standardized production processes and strict quality checks at every step: from raw material inspection to final testing, each batch is documented with a certificate of analysis. We also use advanced machinery to ensure uniform wire diameter and flux coating, so every spool in your bulk order performs the same way.

Can your welding electrode company help us meet regional certification requirements for our market?

Absolutely, our welding electrode company holds global certifications like CE, ABS, and BV, and we can provide additional documentation or adjust products (if needed) to meet regional standards in your market. Our team will work with you to ensure compliance, so you can sell with confidence.

What makes your welding rod manufacturing company’s “GREAT MASTER” rods different from others?

Our welding rod manufacturing company’s “GREAT MASTER” rods are built on our brand’s “masterpiece” idea: we use higher-purity raw materials, invest in R&D to improve performance, and listen to user feedback to refine our products. This results in rods that have better arc stability, deeper penetration, and fewer defects than ordinary options.

Does your welding electrode manufacturer have a plan to expand supply capacity for future wholesale demand?

Yes, our welding electrode manufacturer is growing to match your future needs: we’re opening a branch factory in 2024 to expand production capacity, and we’re investing in new machinery to increase efficiency. This ensures we can handle your growing bulk orders, even as your business expands into new markets.

-

What is a medium-frequency pulse? What types of welding are suitable for?NuusNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NuusNov.21,2025

-

Welding Knowledge 6NuusNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NuusNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NuusNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NuusNov.17,2025