304 tig welding wire factory

304 TIG Welding Wire Factory A Comprehensive Overview

In the realm of metal fabrication and welding, the choice of materials used in the welding process is crucial for achieving strong, durable, and aesthetically pleasing results. One such material that has gained significant attention in the industry is 304 stainless steel TIG welding wire. Known for its excellent corrosion resistance and exceptional mechanical properties, 304 stainless steel is widely used across various sectors, including food processing, chemical industries, and construction. This article delves into the intricacies of a 304 TIG welding wire factory, exploring its operations, production processes, and quality control measures.

The Importance of 304 Stainless Steel

304 stainless steel, an austenitic alloy, primarily consists of chromium and nickel. It is non-magnetic in nature and possesses a remarkable ability to resist oxidation and corrosion, making it an ideal choice for applications that require both durability and hygiene. Commonly referred to as 18/8 stainless steel due to its composition of 18% chromium and 8% nickel, 304 stainless steel is frequently used in the manufacture of kitchen equipment, storage tanks, and piping systems.

The Role of a TIG Welding Wire Factory

A 304 TIG welding wire factory specializes in producing high-quality welding wires designed to work specifically with 304 stainless steel. The factory plays a vital role in supplying the welding industry with the necessary materials for various applications, including structural steel work, pipe welding, and food-grade manufacturing. The factory must adhere to stringent regulatory standards to ensure that the welding wires are produced to meet both domestic and international specifications.

Production Process

The production process in a 304 TIG welding wire factory is multifaceted and involves several key steps

1. Raw Material Sourcing The first step in the production of 304 TIG welding wire is sourcing high-quality raw materials. The primary materials used are stainless steel scrap and alloying elements that meet the required specifications. These materials are obtained from reputable suppliers to ensure the highest quality.

2. Melting and Alloying The raw materials are then melted in a high-temperature electric arc furnace. During this process, careful control of the chemical composition is implemented to ensure that the final product meets 304 stainless steel standards. The molten metal is then cast into billets for further processing.

3. Drawing and Annealing The billets are preheated and rolled into thin wires through a series of drawing processes. This involves feeding the metal through a series of progressively smaller dies to achieve the desired diameter. Annealing is also performed to relieve internal stresses in the metal, ensuring it maintains its desired characteristics.

304 tig welding wire factory

4. Surface Treatment After drawing, the wires undergo surface treatments to enhance their corrosion resistance. This may involve pickling and passivation processes that remove any scale or oxidation from the surface, ensuring a clean and smooth finish.

5. Spooling and Packaging The finished TIG welding wire is then wound onto spools or coils for easy handling and transport. Proper packaging is essential to protect the wire from environmental contaminants during storage and shipment.

Quality Control Measures

Quality assurance is paramount in a 304 TIG welding wire factory. Several measures are taken to ensure that the welding wire produced meets the highest standards

- Chemical Composition Analysis Regular testing of the raw materials and finished products is conducted to verify that the chemical composition aligns with 304 stainless steel specifications.

- Mechanical Testing Tensile strength, elongation, and hardness tests are performed to ensure that the welding wire exhibits the necessary mechanical properties for effective welding.

- Visual Inspection The wires undergo a visual inspection to detect any surface defects or inconsistencies that may affect their performance.

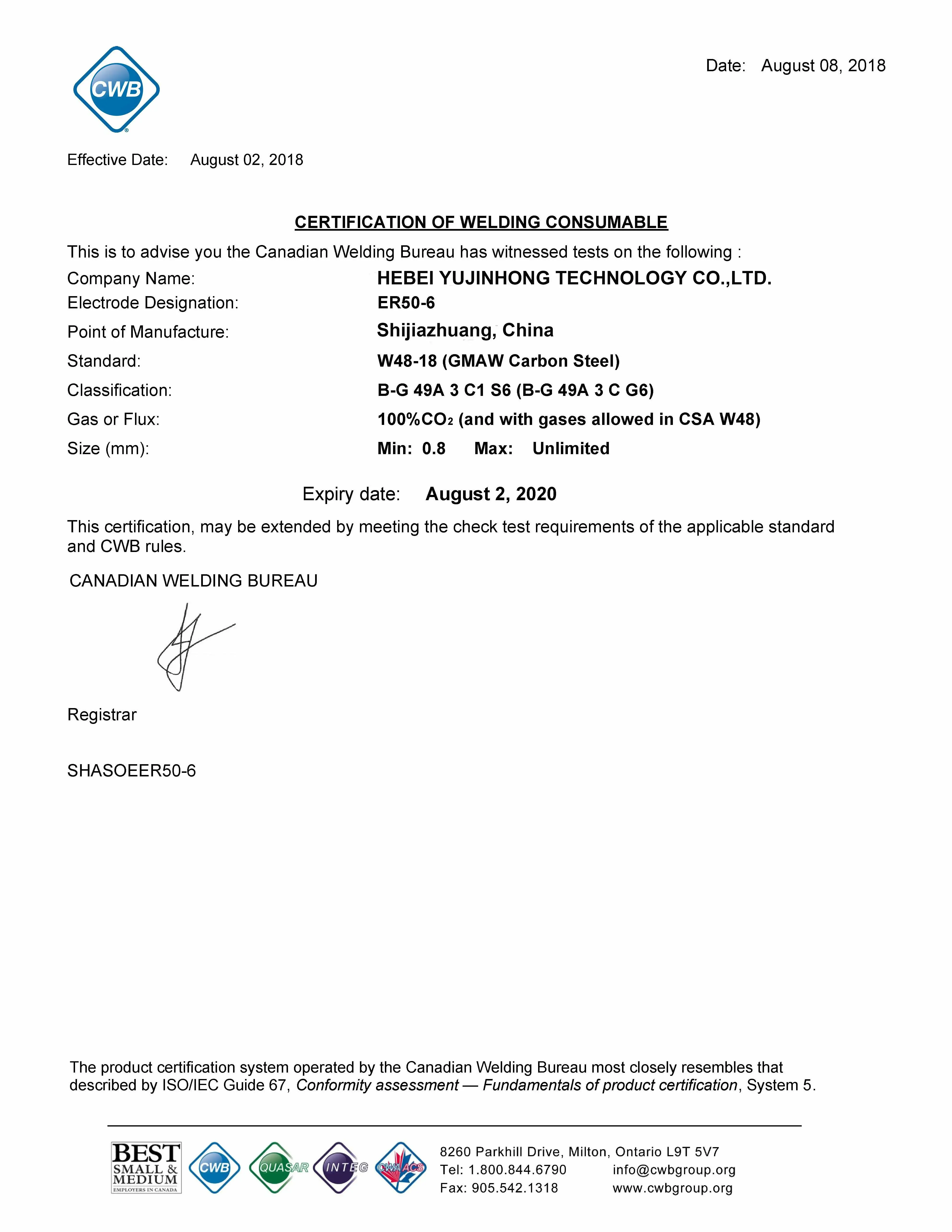

- Certifications The factory often seeks certifications from recognized organizations to bolster credibility and assure customers of the quality of their products.

Conclusion

The operations of a 304 TIG welding wire factory are a testament to modern manufacturing techniques and quality assurance practices. By leveraging high-quality raw materials, advanced production processes, and rigorous quality control measures, these factories ensure the consistent supply of reliable TIG welding wire to meet the diverse needs of various industries. As the demand for high-performance welding materials continues to evolve, the role of such factories remains pivotal to the success of metal fabrication and welding projects globally.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025