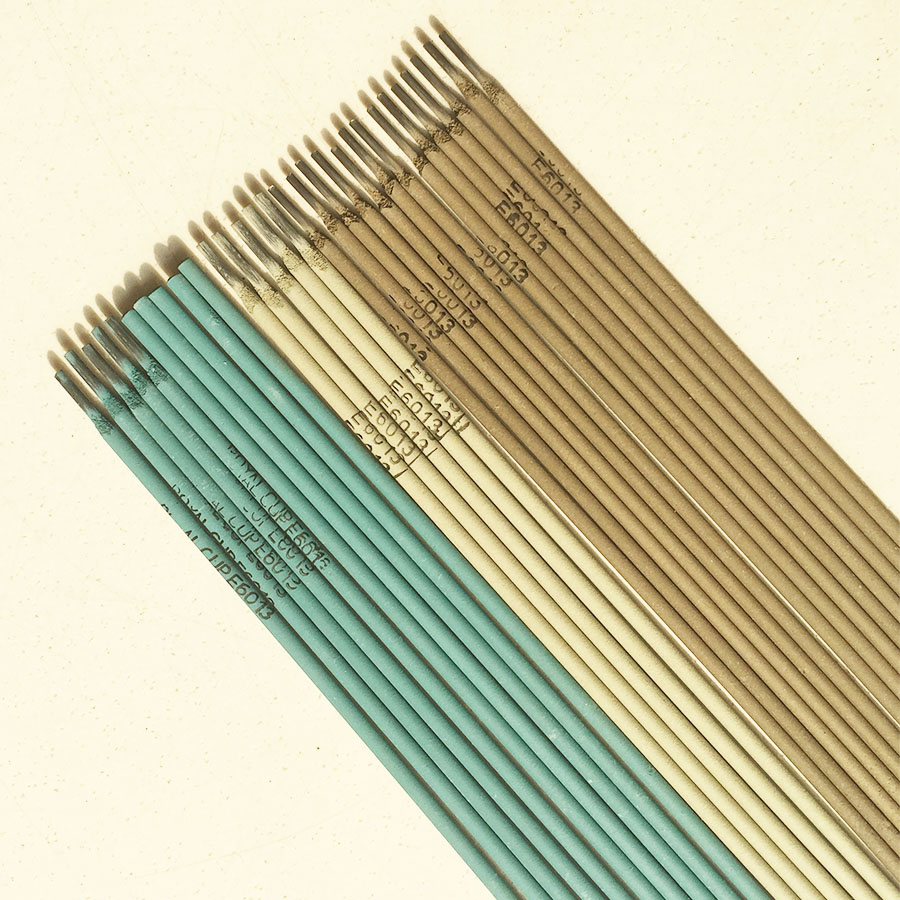

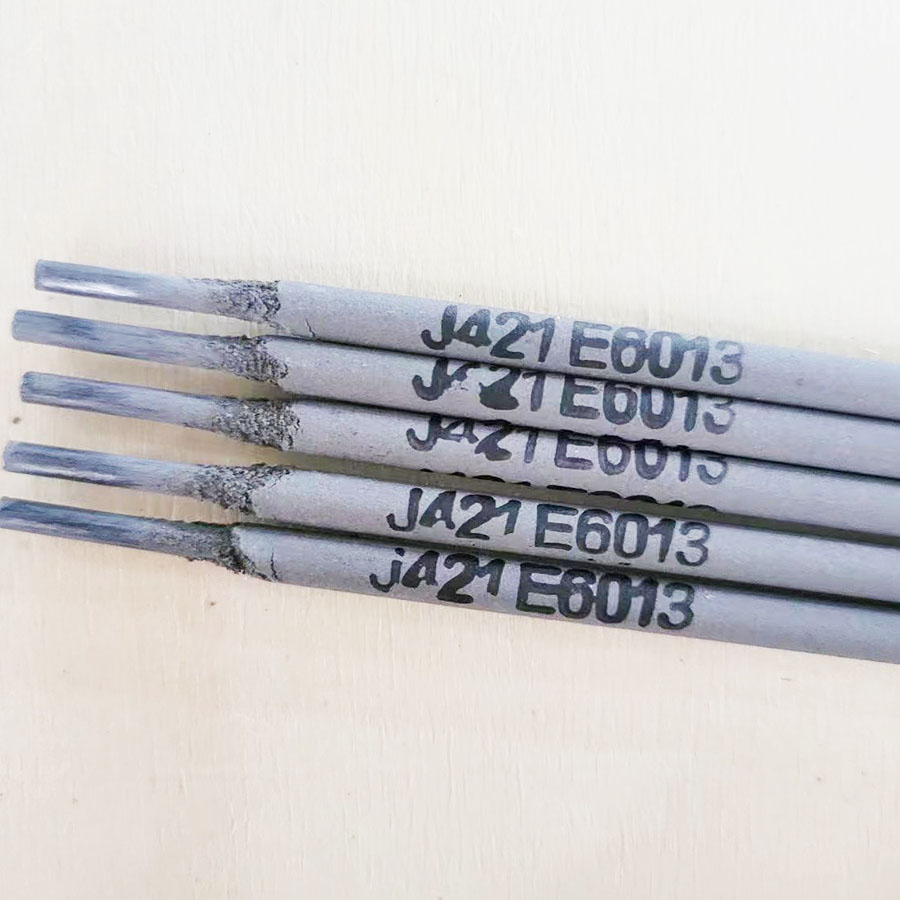

J422 Welding Rod: Durable Electrodes for Strong Welds

The J422 welding rod (often referenced as j422 electrode or welding electrode j422) stands as one of the foundation consumables powering global infrastructure, from petrochemical plants to steel fabrication. In this comprehensive guide, we explore the technical parameters, manufacturing workflow, industry certifications, and real-world application scenarios of j422 welding rod, focusing on the leading product: Best Arc J422 6013 Welding Rod Electrodo E6013 3/32.

Industry Overview & Global Demand Trends

According to MarketsandMarkets, the global welding consumables market reached a value of USD 12.5 billion in 2023, with mild steel electrodes—especially j422 welding rod types—contributing significantly to sector growth. Common industries leveraging J422 series include:

- Petrochemical (30%)

- Shipbuilding (22%)

- Structural Steel Fabrication (18%)

- Water & Pipeline (16%)

- Automotive & Equipment Manufacturing

Technical Specifications: J422 Welding Rod at a Glance

| Parameter | Value/Range | Description |

|---|---|---|

| Standard | GB/T5117 E4303; AWS E6013; ISO 2560-A-E 38.0 R 11 | Compliance with China, US, and International standards ensures versatility. |

| Diameter (mm) | 2.0 / 2.5 / 3.2 / 4.0 / 5.0 | Common diameters for manual stick arc welding. |

| Length (mm) | 300 / 350 / 400 / 450 | Adaptable for various weld depths and access requirements. |

| Coating Type | Rutile | Improves arc stability, slag removability, and surface finish. |

| Welding Current (A) | 40–170 (AC/DC) | Wide current compatibility for process flexibility. |

| Tensile Strength (MPa) | ≥ 420 | Ensures structural reliability, meeting ISO/AWS requirements. |

| Impact Toughness (J, -30°C) | ≥ 27 J | Maintains weld integrity at low temperatures. |

| Welding Position | All positions (1G, 2G, 3G, 4G) | Highly versatile, suitable for overhead, vertical, horizontal, flat. |

| Deposition Efficiency (%) | 65–75 | Indicates weld metal coverage and productivity. |

| Main Applications | Steel fabrication, pipeline, construction, repair | Universal mild steel welding electrode. |

Manufacturing Process of J422 Welding Rod

High-quality mild steel wire, rutile powder, and binder chemicals; All incoming materials tested per ISO 9001.

Steel core wire drawn to precise diameter (2.5/3.2/4.0mm), straightened by automated CNC rollers.

Proprietary rutile coating prepared and extruded onto wire core; Uniform layering ensures arc stability.

Electrodes cut to length and dried/baked at 350–400°C to ensure moisture content

Each j422 electrode batch subjected to mechanical, chemical, and radiographic testing per AWS/ISO/GB standards.

Packed in 5/20kg cartons with vacuum inner pack; Traceability QR code printed for each lot.

Key Technical Advantages of J422 Electrode

- Exceptional Arc Stability:

- Rutile-based flux delivers smooth, low-spatter arc under both AC and DC.

- Superior to cellulose or basic coated rods in ease of operation (less technical barrier for operators).

- Low Hydrogen Content:

- Factory-controlled baking limits hydrogen—reducing risk of cold or delayed cracking in welds.

- Supports higher weld quality and X-ray passing rate (>98%).

- All-position Capability:

- Can be used vertically up/down, overhead, or horizontal; ideal for pipe and structural weld-out.

- Corrosion Resistance:

- Low-sulfur, low-phosphorus core wire meets industry anti-rust standards; prolonged weld service life.

- High Deposition Efficiency:

- Up to 75%, meaning less rod changeover and higher productivity.

- Certified Quality:

- Compliant with ISO 2560, ANSI/AWS A5.1; passed third-party mechanical and radiographic testing.

Brand & Manufacturer Comparison

- ISO 9001/14001 certified

- OEM/ODM available for custom flux coating

- Automated CNC manufacturing

- Full batch traceability

- Strict third-party testing (SGS/BV)

- Strong presence in Asia, Europe, Africa

- Global certifications

- Mostly standard product lineup

- Manual/Partial automatic process

- Limited customization options

- Good after-sale service

| Feature | Best Arc J422 | Lincoln/Tianjin/Other |

|---|---|---|

| Customization | Yes (flux, cut, packaging) | Limited |

| Product Traceability | QR code, batch-to-process linked | Serial number |

| Certifications | ISO 2560, ISO 14001, ISO 9001 | AWS, GB, ISO 9001 |

| Global Support | 24/7, Multi-language | Business hours |

| Cost Effectiveness | High | Medium |

Data Visualization: J422 Welding Rod Performance Metrics

Custom J422 Welding Rod Solutions

The Best Arc J422 6013 Welding Rod Electrodo E6013 3/32 is available in multiple diameters and packaging formats. We provide custom solutions for global clients, including:

- Special flux composition for high sulphur/critical steel

- OEM/branding and custom QR traceability for project batch tracking

- Heat-resistant, anti-moisture packaging for tropical/sub-arctic regions

- Technical consulting for weld procedure qualification (WPQR)

- Express sample delivery & production cycle tracking

J422 Welding Rod Application Scenarios & Case Studies

- Petrochemical Industry: Used in the main structural weld-out for refineries in Saudi Arabia, passing 100% radiographic (RT) and ultrasonic (UT) testing under ISO/ANSI inspection.

- Pipeline/Water Supply: Supplied to African municipal contractors for potable water supply and pipeline welding; achieved field repair speed increase by 20% due to easy slag removal.

- Structural Steel Fabrication: Utilized in bridge and stadium construction in Southeast Asia, meeting rapid assembly deadlines and welding at various positions.

- General Equipment Repair: Popular for multi-brand machinery and automotive workshops—handle patching, frame/axle repairs easily.

A recent case (2023), working with an Indonesia refinery EPC, reduced weld rejection rates to below 1.8% for shop and field fabrication by using our j422 welding rod batch under ISO 3834 oversight.

User Experience & Field Feedback

“We’ve tried several brands, but the Best Arc J422 6013 Welding Rod stands out for its low spatter and perfect arc for all-position pipe welding. No issues with moisture pickup, even during the rainy season. Inspection passed at first attempt.”

— Liu Jian, Site Welding Foreman (Shipbuilding, Dalian, China)

"Delivered two days ahead of schedule, and achieved required RT acceptance. Our welders reported j422 electrode performed with less arc blow compared to previous batches.”

— Daniel Marasa, Pipeline Supervisor (Ghana Water Works)

Certifications, Delivery, Warranty & Support

-

Certifications: ISO 9001/14001, ISO 2560, SGS and BV inspection ready, GB/T5117, AWS A5.1

Continuous compliance with evolving international welding standards. -

Delivery: Standard production lead time 7–10 working days

(Expedited 3–5 days available for urgent projects; global delivery partners: DHL, Maersk, COSCO) - Warranty: 12 months shelf life from factory shipping date; full replacement for any certified batch defect.

- Support: 24/7 technical and after-sales assistance (English, Spanish, Russian, Arabic, Chinese)

- Traceability: QR code and batch certificate included.

FAQ: Professional Questions on J422 Welding Rod

(E.g., 3.2mm: 90–130A typical)

Start Your Project with Proven J422 Welding Rod Quality

For full technical documentation, custom supply requests, or to discuss OEM partnership, please contact our expert team. We ensure each batch of j422 welding rod is delivered with traceable, certified excellence, trusted by leading EPCs and contractors worldwide.

[1] MarketsandMarkets: Global Welding Consumables Market

[2] WeldingWeb industry forum: E6013 vs E7018 Discussion

[3] ISO 2560: Welding consumables — Covered electrodes

[4] AWS A5.1: A5.1: Specification for Carbon Steel Electrodes

[5] AWC Journal: Tensile Properties of Carbon Steel Electrodes

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025