China Manufacturers of Gasless MIG Welding Wire for Efficient Welding Solutions

The Rise of Gasless MIG Welding Wire Manufacturers in China

In recent years, China has emerged as a cornerstone in the global manufacturing landscape, particularly in specialized industries such as welding. Among the various welding technologies, gasless MIG (Metal Inert Gas) welding has gained considerable attention due to its efficiency, ease of use, and versatility. This article explores the growing market for gasless MIG welding wire manufacturers in China and the implications for the industry globally.

Gasless MIG welding, also known as flux-cored arc welding (FCAW), is a popular choice among welders for its ability to operate without an external shielding gas. This characteristic makes it particularly advantageous for outdoor applications, where wind can easily disperse shielding gases used in traditional MIG welding. The development of high-quality gasless MIG welding wires has allowed manufacturers to offer reliable solutions for various sectors, including construction, automotive, and manufacturing.

Chinese manufacturers have rapidly adopted advanced technologies to produce gasless MIG welding wires that meet international standards. The country boasts a robust supply chain, abundant raw materials, and a skilled workforce, which collectively enhance the production capabilities of welding wires. Companies such as Jiangsu Saner Group, Shanghai Shenda Group, and others have made significant strides in producing high-quality welding consumables that cater to both domestic and international markets.

china gasless mig welding wire manufacturers

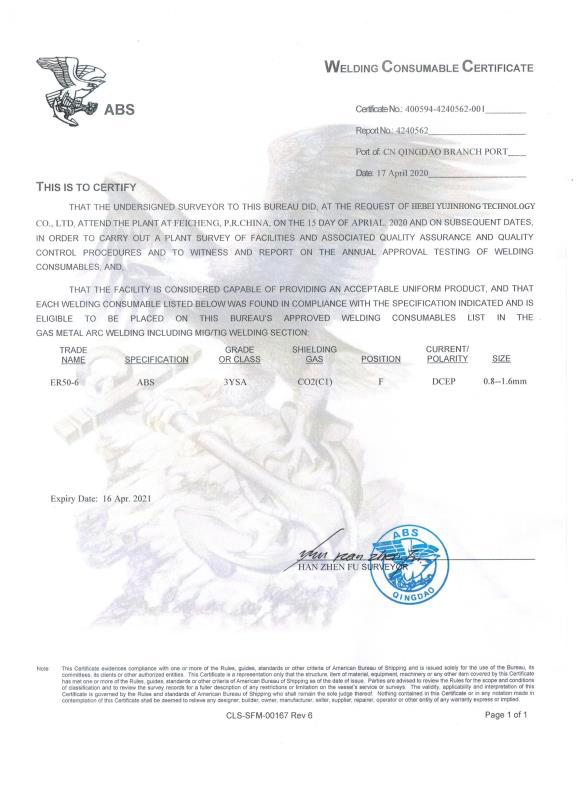

As quality control becomes increasingly important in the global market, Chinese gasless MIG welding wire manufacturers have begun to implement strict quality assurance protocols. Certifications such as ISO 90012015 are commonly pursued to demonstrate compliance with international quality standards. By focusing on quality and consistency, these manufacturers can compete more effectively against established names in the welding industry worldwide.

The demand for gasless MIG welding wires is being driven by the growing need for versatile welding solutions. Industries are increasingly opting for gasless welding to improve efficiency and reduce operational costs. The ability to weld in various environments without the need for an external gas supply is a significant advantage that enhances productivity on job sites. Moreover, as companies look to optimize their welding processes, the demand for high-performance welding wires continues to rise.

Furthermore, the global push towards automation and advanced manufacturing technologies has influenced the gasless MIG welding sector. Manufacturers in China are not just producing wires; they are also developing systems and automation solutions that integrate with these products. This trend represents a shift towards more sophisticated welding solutions that allow for greater precision and control.

In conclusion, the rise of gasless MIG welding wire manufacturers in China signifies a transformative period in the welding industry. With a commitment to quality, innovation, and responsiveness to market demands, these manufacturers are set to play a pivotal role in shaping the future of welding globally. As industries continue to evolve and prioritize efficiency, China is well-positioned to lead the charge in supplying high-quality gasless MIG welding wires to meet the diverse needs of customers around the world.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025