china mig flux core welding wire factories

The Landscape of MIG Flux Core Welding Wire Factories in China

MIG (Metal Inert Gas) welding has become an essential technique in various industries, including construction, automotive, and manufacturing. Among the many advancements in welding technology, flux core welding wire plays a crucial role, enhancing the efficiency and effectiveness of the MIG welding process. In China, a country that has firmly established itself as a global manufacturing hub, the production of MIG flux core welding wires has garnered significant attention.

Overview of MIG and Flux Core Welding

MIG welding utilizes a continuous solid wire electrode that feeds into a welding gun, where it melts and forms a weld joint. Flux core welding is a variant of MIG welding that uses a tubular wire filled with flux. This flux not only provides a shielding effect to protect the molten weld pool from contamination by atmospheric gases but also improves the quality and stability of the weld. By using flux core wire, welders can work in various positions and conditions that might not be suitable for traditional MIG welding.

The Growth of Welding Wire Manufacturing in China

The rise of the welding wire manufacturing industry in China can be attributed to several factors. Firstly, the robust demand from industries such as shipbuilding, construction, and the automotive sector has fueled this growth. As these sectors expand, the need for high-quality welding materials increases, prompting manufacturers to invest in advanced technologies and explore new materials.

Chinese factories specializing in MIG flux core welding wire have made significant strides in research and development. Many manufacturers have embraced innovative techniques to enhance the performance of their products. For instance, they are focused on improving the mechanical properties of the wire, optimizing the flux composition, and ensuring better usability in various welding environments.

Quality Standards and International Competition

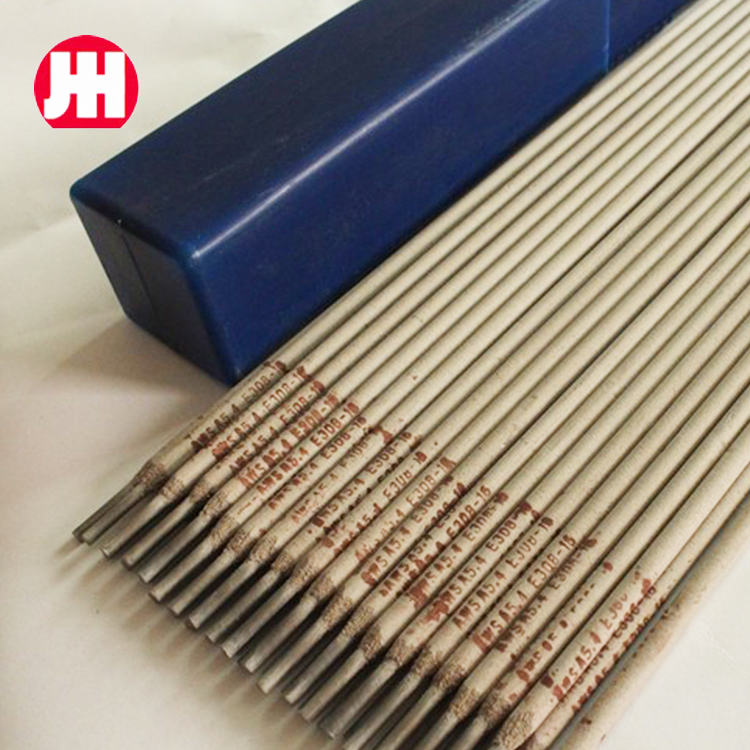

china mig flux core welding wire factories

As the global market tightens, Chinese MIG flux core welding wire factories are increasingly aware of the need to meet international standards. Many of these manufacturers have received certifications such as ISO 9001, which underscores their commitment to quality management systems. Through such certifications, they are not only aiming to improve their product quality but also to enhance their positioning in the global market.

Competition in the welding wire market is fierce, with manufacturers from countries like the USA, Germany, and Japan vying for market share. To maintain their edge, Chinese factories are focusing on research and development to create superior products. By integrating advanced technology and automation into their production lines, they are able to produce flux core wires that offer better performance, including improved deposit rates, reduced spatter, and enhanced arc stability.

Environmental Considerations in Production

In addition to quality and competitiveness, environmental concerns have come to the forefront in the manufacturing processes of MIG flux core welding wires. The Chinese government has introduced several regulations aimed at reducing emissions and promoting sustainable production practices. As a response, many factories are adopting greener technologies, such as recycling waste materials and reducing energy consumption in their manufacturing processes.

Some companies are also investing in R&D to develop environmentally-friendly flux compositions that maintain performance while minimizing harmful emissions during the welding process.

Future Prospects

Looking ahead, the future of MIG flux core welding wire manufacturing in China appears promising. With the ongoing industrial upgrades and the push for innovation, Chinese manufacturers are likely to expand their product offerings and enhance their capabilities. As global demand for high-quality welding materials continues to rise, these factories are well-positioned to play a significant role in shaping the industry's future.

In conclusion, the MIG flux core welding wire factories in China are evolving rapidly. Their commitment to quality, innovation, and sustainability will not only bolster their domestic market but also ensure they remain competitive on the world stage. As industries continue to embrace advanced welding technologies, the role of these factories will be more significant than ever in meeting the demands of a dynamic global market.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025