فبراير . 20, 2025 13:23

Back to list

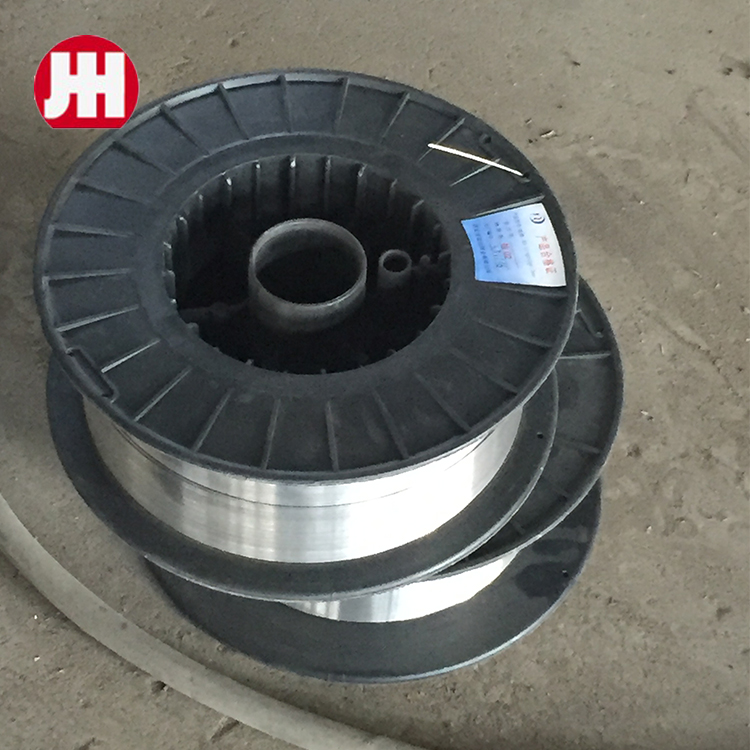

SG2 SG3 soldering Welding Wire er70s-6

China's MIG wire for soldering has become a pivotal element in various industries, playing a significant role in ensuring quality and efficiency in production processes. From automotive to electronics, the application of China MIG wire is diverse, offering vibrant opportunities for both small-scale and large industries.

The authoritativeness of Chinese MIG wires is further established through strategic partnerships with numerous international corporations, which continually showcase the reliability of these products on a global stage. Collaborations with industries worldwide underline the strength and trustworthiness of China as a leading supplier of MIG wires. Testimonials from multinational companies often highlight the significant improvements in production efficiency and cost savings attributed to switching to Chinese-made MIG wires. In terms of trustworthiness, Chinese suppliers are increasingly transparent about their manufacturing processes, offering detailed insights into the sourcing of raw materials and the rigorous testing each batch undergoes before reaching the consumer. This transparency has built considerable trust with international clients, reassuring them of the superior quality and reliability of their products. Moreover, environmental considerations have also been integral to China's approach to manufacturing MIG wires. Manufacturers are progressively adopting environmentally friendly practices, such as reducing emissions and incorporating recycling processes in their production lines. These efforts not only help in conserving resources but also align with the global demand for sustainable industrial practices. In conclusion, China’s MIG wire for soldering embodies a perfect blend of quality, economy, and reliability. For industries seeking to optimize their soldering processes, these wires present an appealing option due to their superior performance, adherence to international standards, and the cost benefits they bring. The commitment of Chinese manufacturers to continuously improve and innovate in this space ensures that their MIG wire remains at the forefront of the global market. Businesses across sectors can confidently rely on Chinese MIG wires to enhance their operations, assured by the product's robust performance and the ethical standards upheld during its production.

The authoritativeness of Chinese MIG wires is further established through strategic partnerships with numerous international corporations, which continually showcase the reliability of these products on a global stage. Collaborations with industries worldwide underline the strength and trustworthiness of China as a leading supplier of MIG wires. Testimonials from multinational companies often highlight the significant improvements in production efficiency and cost savings attributed to switching to Chinese-made MIG wires. In terms of trustworthiness, Chinese suppliers are increasingly transparent about their manufacturing processes, offering detailed insights into the sourcing of raw materials and the rigorous testing each batch undergoes before reaching the consumer. This transparency has built considerable trust with international clients, reassuring them of the superior quality and reliability of their products. Moreover, environmental considerations have also been integral to China's approach to manufacturing MIG wires. Manufacturers are progressively adopting environmentally friendly practices, such as reducing emissions and incorporating recycling processes in their production lines. These efforts not only help in conserving resources but also align with the global demand for sustainable industrial practices. In conclusion, China’s MIG wire for soldering embodies a perfect blend of quality, economy, and reliability. For industries seeking to optimize their soldering processes, these wires present an appealing option due to their superior performance, adherence to international standards, and the cost benefits they bring. The commitment of Chinese manufacturers to continuously improve and innovate in this space ensures that their MIG wire remains at the forefront of the global market. Businesses across sectors can confidently rely on Chinese MIG wires to enhance their operations, assured by the product's robust performance and the ethical standards upheld during its production.

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025