CO2 Gas Shielded Copper Plated Micro Wire - Hebei Yujinhong Technology | Precision Welding, High Efficiency

Introduction to CO2 Gas Shielded Welding Technology

Welding is a critical process in modern manufacturing, and CO2 gas shielded welding has emerged as a preferred method due to its cost-effectiveness and versatility. This technology utilizes a shielding gas, such as CO2 or a mixture of argon and CO2, to protect the weld pool from atmospheric contamination. Among the various types of welding wires, the CO2 gas shielded copper-plated micro wire stands out for its advanced properties and wide-ranging applications.

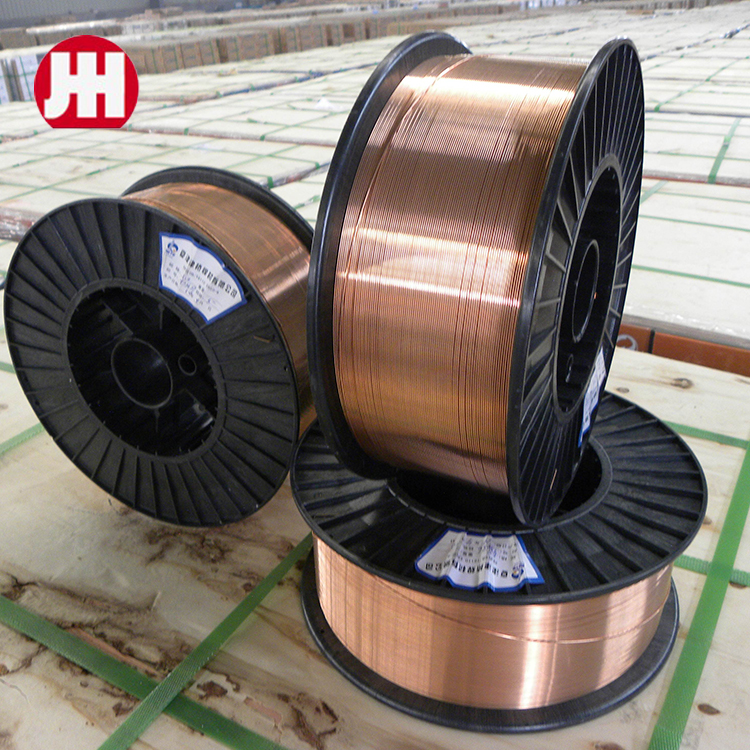

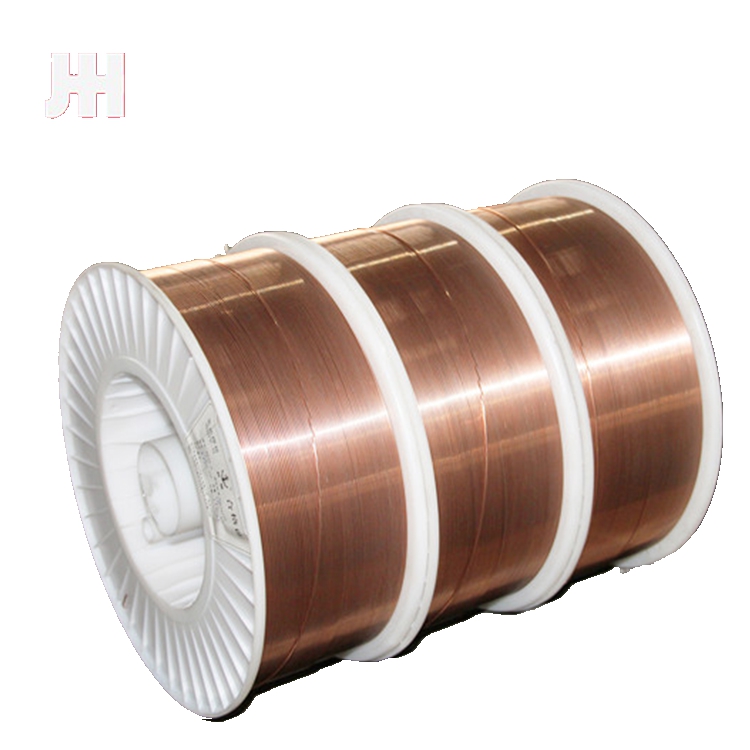

Product Overview: ER70S-6 Carbon Steel Wire

The ER70S-6 is a 500MPa-level carbon steel welding wire designed for CO2 or 80% argon + 20% CO2 gas shielded arc welding. This wire is engineered to deliver exceptional performance in various industrial settings. Key features include:

- Low Spatter: Minimizes welding spatter, resulting in a clean and aesthetically pleasing weld appearance.

- High Cladding Efficiency: Ensures efficient deposition of weld metal, reducing material waste and labor costs.

- Excellent Processability: Suitable for all welding positions, including PA, PB, PC, PD, PE, and PF, making it ideal for complex and challenging projects.

- Corrosion Resistance: The copper plating on the wire surface enhances oxidation and corrosion resistance, extending the product's shelf life.

Key Advantages of CO2 Gas Shielded Welding Wire

The CO2 gas shielded welding wire offers several advantages that make it a preferred choice in the welding industry:

- Low Cost: Compared to other welding methods, CO2 gas shielded welding reduces material and energy consumption, making it a cost-effective solution.

- High Production Efficiency: The process is fast and efficient, with minimal downtime and high productivity.

- Easy Operation: The wire's stable arc and minimal spatter make it user-friendly, even for less experienced welders.

- Low Hydrogen and Nitrogen Content: This reduces the risk of cracks and ensures a high-quality weld with excellent mechanical properties.

- Minimal Deformation: The welding process minimizes distortion in the workpiece, preserving the structural integrity of the material.

- Wide Application Range: Suitable for welding thin, medium, and thick plates, the wire is versatile and adaptable to various industrial needs.

Technical Specifications of CO2 Gas Shielded Copper-Plated Micro Wire

| Parameter | Details |

|---|---|

| Wire Type | ER70S-6 Carbon Steel Wire |

| Shielding Gas | CO2 or 80% Ar + 20% CO2 |

| Welding Positions | السلطة الفلسطينية ، PB ، الكمبيوتر الشخصي ، PD ، PE ، PF |

| قوة الشد | 500 MPa |

| Spatter Level | Low |

| Corrosion Resistance | Enhanced by Copper Plating |

| Electrical Conductivity | Improved with Smooth Surface |

| Application Range | Thin, Medium, and Thick Plates |

Applications in Industrial Manufacturing

The CO2 gas shielded copper-plated micro wire is widely used in various industrial sectors, including:

- Automotive Industry: For welding car frames, chassis, and other structural components.

- Construction: In the fabrication of steel structures, bridges, and high-rise buildings.

- Shipbuilding: For joining steel plates in ship hulls and internal structures.

- Manufacturing: In the production of machinery, equipment, and industrial tools.

- Energy Sector: For welding pipelines, storage tanks, and other critical infrastructure.

Its ability to handle different plate thicknesses and welding positions makes it a versatile solution for complex projects.

Company Background: Hebei Yujinhong Technology Co., Ltd.

Hebei Yujinhong Technology Co., Ltd. is a leading manufacturer of high-quality welding consumables, specializing in the production of CO2 gas shielded welding wire. With a commitment to innovation and excellence, the company employs advanced production technology and strict quality control measures to ensure the reliability and performance of its products.

Hebei Yujinhong's dedication to precision and customer satisfaction has earned it a reputation as a trusted supplier in the welding industry. The company's focus on research and development has led to the creation of products that meet the highest standards of quality and efficiency.

Quality Assurance and Industry Standards

The CO2 gas shielded copper-plated micro wire is produced in compliance with stringent industry standards. Hebei Yujinhong Technology Co., Ltd. adheres to the principles of NIST (National Institute of Standards and Technology) guidelines, ensuring that its products meet the requirements for precision, reliability, and safety. According to NIST, "The role of standards in driving innovation and ensuring interoperability is critical in advancing technology across industries" (NIST, 2025).

The company's rigorous testing processes, from raw material selection to finished product inspection, guarantee that each batch of welding wire meets the highest quality benchmarks. This commitment to excellence is reflected in the wire's consistent performance and durability.

Conclusion: The Future of Welding Technology

The CO2 gas shielded copper-plated micro wire represents a significant advancement in welding technology, offering a combination of efficiency, cost-effectiveness, and reliability. With its ability to handle diverse applications and its adherence to industry standards, this product is poised to become a cornerstone of modern manufacturing.

As the demand for high-performance welding solutions continues to grow, Hebei Yujinhong Technology Co., Ltd. remains at the forefront of innovation, delivering products that meet the evolving needs of the industry. By integrating advanced technology and a commitment to quality, the company is shaping the future of welding and contributing to the advancement of global manufacturing.

-

What is a medium-frequency pulse? What types of welding are suitable for?أخبارNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?أخبارNov.21,2025

-

Welding Knowledge 6أخبارNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?أخبارNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?أخبارNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016أخبارNov.17,2025