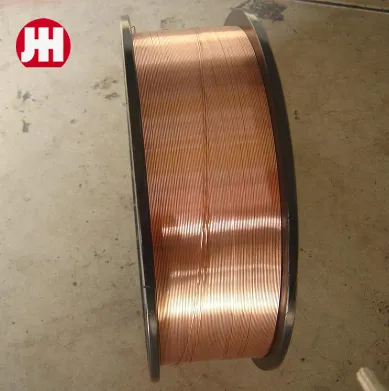

Enhance Welding Efficiency with Premium Copper Coated Welding Wire

In modern welding applications, material quality is paramount to achieving strong, durable, and aesthetically pleasing welds. Among the essential consumables, copper coated welding wire stands out for its superior performance, especially in carbon steel welding. Designed to optimize the MIG welding process, this wire offers excellent conductivity, resistance to oxidation, and improved feeding through welding machines. Whether working in industrial fabrication or precision metal joining, adopting copper coated mig welding wire ensures stable arc performance, minimal spatter, and outstanding bead appearance. This article delves into the advantages, technical features, and diverse applications of copper-coated wires, while guiding you on choosing the right product for your welding projects.

Superior Performance of Copper Coated Welding Wire in Carbon Steel Welding

The copper coated welding wire commonly used for carbon steel, such as the ER70S-6 variant, is engineered to provide consistent strength and excellent weld quality. This wire is typically rated at 500MPa tensile strength, making it suitable for demanding applications requiring high mechanical performance. When used with shielding gases like CO2 or mixed argon-CO2 blends (80% Ar + 20% CO2), it produces minimal spatter, reducing post-weld cleanup and improving overall efficiency.

Thanks to its copper coating, the wire exhibits enhanced electrical conductivity and corrosion resistance. This coating prevents oxidation on the wire surface, which could otherwise lead to inconsistent feeding and arc instability. The copper coated welding wire also contributes to improved arc ignition and a smooth, stable welding process that performs well in all welding positions. Such reliability is critical in sectors like automotive, shipbuilding, and heavy machinery fabrication where precision and consistency dictate operational success.

Why Choose Copper Coated MIG Welding Wire for Modern Fabrication

MIG welding demands consumables that feed smoothly and produce clean welds without interruption. The copper coated mig welding wire is designed precisely to meet these needs. The copper layer reduces friction in the welding wire feeder system, which minimizes wire jams and feed inconsistencies that can compromise weld integrity. This results in higher productivity with fewer machine stoppages.

Moreover, the copper coated mig welding wire ensures a stable arc with low spatter, which enhances the weld bead’s uniformity and surface finish. This characteristic is especially valuable for applications where cosmetic appearance matters, such as automotive body panels and decorative metalwork. The wire’s optimized chemistry supports deep penetration and mechanical toughness, meeting stringent industry standards for structural integrity.

Using copper coated wire also extends the lifespan of welding equipment by reducing wear on feed rollers and contact tips, delivering long-term cost savings. Overall, the copper coated mig welding wire provides welders with a reliable, user-friendly consumable that enhances both quality and efficiency.

Application and Benefits of Copper Coated MIG Wire in All-Position Welding

The versatility of the copper coated mig wire shines through in its excellent performance across all welding positions—flat, horizontal, vertical, and overhead. Its stable arc and fast-freezing slag facilitate ease of welding on complex geometries and hard-to-reach areas without sacrificing weld quality.

In industrial environments where production speed and weld consistency are critical, the copper coated mig wire offers superior cladding efficiency and low weld metal porosity sensitivity. This means stronger, more uniform welds with less risk of defects such as porosity or slag inclusions. Its adaptability to different gas mixtures and welding parameters makes it an ideal choice for diverse fabrication challenges.

The wire’s resistance to oxidation and corrosion translates to reliable storage and handling, ensuring that welders can maintain consistent performance even under variable environmental conditions. The copper coated mig wire thus becomes an indispensable part of modern welding workshops focused on precision, reliability, and efficiency.

Enhancing Structural Integrity with Copper Coated Mild Steel Wire

At the heart of many fabrication projects is mild steel, valued for its balance of strength, ductility, and affordability. The copper coated mild steel welding wire enhances these properties by ensuring that the filler metal matches or exceeds the base metal’s mechanical characteristics.

The copper coating on mild steel wire facilitates consistent feeding and electrical contact, which are essential for maintaining a strong, clean arc during welding. This results in welds that exhibit excellent tensile strength, impact resistance, and toughness. The copper coated mild steel wire is compatible with CO2 and argon-CO2 shielding gases, providing welds with minimal spatter and superior bead appearance.

From automotive chassis to structural beams and agricultural machinery, this wire type supports a wide range of heavy-duty and precision welding applications. Its ability to produce crack-resistant and corrosion-resistant joints makes it a preferred consumable in construction and manufacturing industries that prioritize longevity and safety.

Copper Coated Welding Wire FAQs

What advantages does copper coating provide on welding wire?

The copper coating on welding wire improves electrical conductivity, which ensures stable arc ignition and consistent welding performance. It protects the wire from surface oxidation, reducing feeding issues like bird-nesting or jamming in the wire feeder. This coating also enhances the lifespan of welding equipment by minimizing wear on contact tips and rollers, contributing to reduced downtime and maintenance costs.

Can copper coated MIG welding wire be used with different shielding gases?

Yes, copper coated MIG welding wire is compatible with a range of shielding gases, including pure CO2 and mixed gases like 80% Argon with 20% CO2. These gas options help optimize arc characteristics, penetration depth, and bead appearance. The wire’s design ensures it performs well under these different shielding conditions, maintaining low spatter and stable arcs.

How does copper coated MIG wire perform in all welding positions?

Copper coated MIG wire delivers excellent arc stability and slag control, allowing it to be used effectively in flat, horizontal, vertical, and overhead welding positions. Its fast-freezing slag and consistent feeding reduce defects and improve weld quality, even in complex or hard-to-access joints. This versatility is valuable for industries requiring multi-position welding capabilities.

What industries benefit most from copper coated mild steel welding wire?

Industries such as automotive manufacturing, shipbuilding, heavy machinery fabrication, construction, and agricultural equipment production benefit significantly from copper coated mild steel welding wire. Its strength, corrosion resistance, and ease of use make it ideal for structural and precision welds that must withstand mechanical stress and environmental exposure.

How does copper coated welding wire reduce spatter during welding?

The chemical composition and copper coating work together to create a stable, smooth arc that minimizes spatter formation. Reduced spatter results from better control of the molten weld pool and consistent metal transfer during welding. This not only improves the appearance of the weld bead but also reduces the need for post-weld cleaning and finishing.

-

What is a medium-frequency pulse? What types of welding are suitable for?أخبارNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?أخبارNov.21,2025

-

Welding Knowledge 6أخبارNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?أخبارNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?أخبارNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016أخبارNov.17,2025