فبراير . 14, 2025 00:21

Back to list

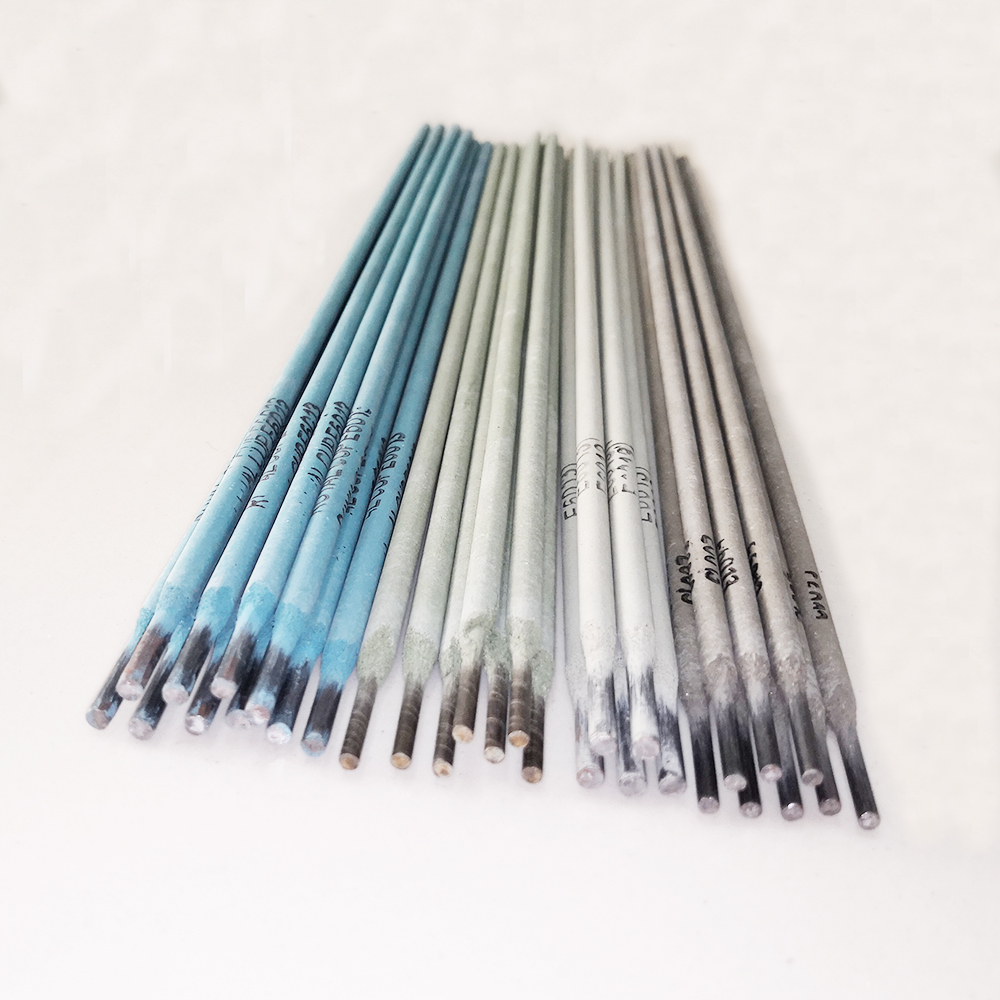

wholesale flux cored welding wire 1.2mm

For anyone in the welding industry, selecting the right consumables is crucial for ensuring high-quality output and efficient work processes. Flux cored welding wire, especially the 1.2mm size, stands out as a versatile solution for both professionals and hobbyists. When you're investing in wholesale quantities, understanding what makes flux cored welding wire an essential tool can not only enhance productivity but also improve the overall quality of your projects. This detailed exploration of 1.2mm flux cored welding wire focuses on the elements that make it a preferred choice for many welders, providing insight into its benefits, applications, and tips for optimal use, drawing from authentic experiences within the industry.

From a trustworthiness perspective, the consistent performance of 1.2mm flux cored welding wire under various environmental conditions makes it a reliable component in welding projects. The wire's formulation is designed to accommodate a variety of parent metals and surface contaminants, providing a level of forgiveness where pre-cleaning might not be feasible. Industries that require dependable performance in less controlled environments often turn to flux cored wire for this reason. Long-term studies and feedback confirm reduced defect rates and improved mechanical properties in welds performed with quality flux cored wires, enhancing the trust in this product for critical applications. When procuring wholesale flux cored welding wire, particularly in the 1.2mm specification, several factors influence the decision-making process. First, ensuring compatibility with the existing welding equipment is critical, as not all welding machines handle flux cored wires with the same efficiency. Next, evaluating the wire manufacturer’s quality assurance measures can provide peace of mind. Reputable suppliers often provide test reports and certifications that validate the wire’s performance characteristics. Moreover, real-world experiences from seasoned welders emphasize the importance of understanding the unique burn-back properties and adjusting machine settings accordingly. The correct voltage and amperage settings are crucial in maximizing wire performance and obtaining defect-free welds. Novices entering the welding field can dramatically improve their skill set by tracing insights from experienced practitioners who have mastered the art of using flux cored wires. The landscape of welding consumables continues to evolve, but the reliability and adaptability of 1.2mm flux cored welding wire secure its place as an invaluable component in both traditional and innovative welding solutions. As industry trends lean towards efficiency and sustainability, welding professionals are encouraged to explore and invest in products that not only meet current operational demands but also align with future requirements.

From a trustworthiness perspective, the consistent performance of 1.2mm flux cored welding wire under various environmental conditions makes it a reliable component in welding projects. The wire's formulation is designed to accommodate a variety of parent metals and surface contaminants, providing a level of forgiveness where pre-cleaning might not be feasible. Industries that require dependable performance in less controlled environments often turn to flux cored wire for this reason. Long-term studies and feedback confirm reduced defect rates and improved mechanical properties in welds performed with quality flux cored wires, enhancing the trust in this product for critical applications. When procuring wholesale flux cored welding wire, particularly in the 1.2mm specification, several factors influence the decision-making process. First, ensuring compatibility with the existing welding equipment is critical, as not all welding machines handle flux cored wires with the same efficiency. Next, evaluating the wire manufacturer’s quality assurance measures can provide peace of mind. Reputable suppliers often provide test reports and certifications that validate the wire’s performance characteristics. Moreover, real-world experiences from seasoned welders emphasize the importance of understanding the unique burn-back properties and adjusting machine settings accordingly. The correct voltage and amperage settings are crucial in maximizing wire performance and obtaining defect-free welds. Novices entering the welding field can dramatically improve their skill set by tracing insights from experienced practitioners who have mastered the art of using flux cored wires. The landscape of welding consumables continues to evolve, but the reliability and adaptability of 1.2mm flux cored welding wire secure its place as an invaluable component in both traditional and innovative welding solutions. As industry trends lean towards efficiency and sustainability, welding professionals are encouraged to explore and invest in products that not only meet current operational demands but also align with future requirements.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025