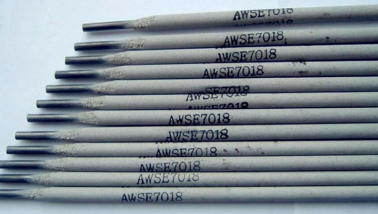

Production Description

E7018 is a multi-purpose electrode with excellent handling properties. 7018 performs especially well when welding mild steel or low alloy steel, such as bridges, construction, shipbuilding and pressure vessel manufacturing, etc. The E7018 can also be used in construction and maintenance of a range of engineering machinery such as bulldozers, agricultural or mining equipment.

AWS E7018 Carbon Steel Electrode Carbon Steel Electrode Description: E7018 is a carbon steel electrode with iron powder and low hydrogen potassium coating. Both AC and DC can be used for all-position welding. Its characteristic is that the coating contains iron powder, which can reduce the number of welding layers. Uses: Suitable for welding carbon steel and low alloy steel, such as 16Mn, etc.

Relevant standards GB/T 5117: E5018 AWS A5.1: E7018 ASME SFA-5.1

User guides

Bake the electrode at 300°C for 60 minutes before use. If the electrode is exposed to the air for a long time, it is recommended to bake at 300-350°C for 60-120 minutes. Welding rods that have been opened should be stored at 100-150°C.

Remove water, dirt, oil, etc. from the metal surface of the base metal before welding to prevent cracks and pores.

The back-and-forward method should be used to prevent air holes or pits at the arc strike.

The arc length should be kept as short as possible during welding. If swinging is required, the swinging range should not exceed 3 times the diameter of the electrode.

E7018 electrode is an alkaline, perovskite type electrode, which belongs to low water hydrogen, low carbon steel electrode. Its electroslag ability is strong, the droplet is easy to be stable and less sputtering, it is suitable for welding various strength grades of low carbon steel and low alloy steel structures, such as straight seams, transverse seams, corner seams, etc., suitable for filling, Back welding, stable tetrahedral arc opening, and strong power supply faults. It is particularly excellent in preventing noise and reducing the risk of explosion. At the same time, it also has the advantages of high output, power saving, and low waste rate. Generally speaking, the E7018 electrode performs better when welding workpieces that require high strength. It has the advantages of almost no spattering in the deposition and good formability, and brings higher comfort and safety to workers during the welding process.

Chemical Composition:

|

C |

Mn |

Si |

S |

P |

|

≤0.12 |

≤1.6 |

≤0.75 |

≤0.035 |

≤0.035 |

Mechanical Property:

|

AWS A5.1 |

Tensile Strength Rm |

Yield Strength Rel |

Elongation A |

Akv |

KV2 |

|

MPa |

MPa |

% |

J |

0 degree/J |

|

|

E7018 |

≥490 |

≥400 |

≥22 |

≥27 |

-30 |

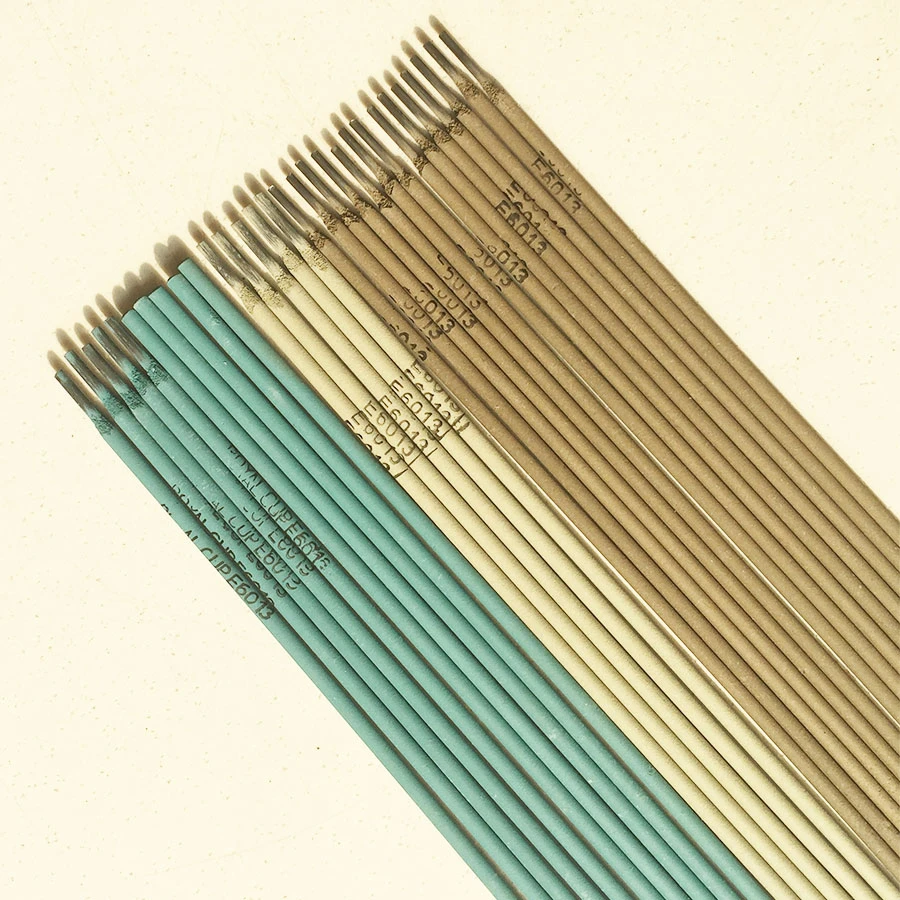

Specification & Package

2.0mm (5/64”) x 300mm, 2.5kgs/box, 20kg(8boxes) per carton.

2.5mm (3/32”) x 300/350mm; 2.5kgs/box, 20kg(8boxes) per carton.

3.2mm (1/8”) x 350mm; 5kgs/box, 20kg(4boxes) per carton.

4.0mm (5/32”) x 400mm; 5kgs/box, 20kg(4boxes) per carton.

5.0mm x 450mm; other size please contact our service.

OEM/ODM Package Available:

NW: 20.00KG,GW: 20.40KG,

we also can do different kgs package, plastic bag package,

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry