Global Growth Powered by a Leading Welding Electrode Supplier

As a global welding electrode supplier, we serve clients across construction, shipbuilding, manufacturing, and energy sectors with consistency, quality, and tailored technical solutions. Our reputation is built on a deep understanding of industry requirements and the ability to deliver high-performance electrodes that exceed expectations.

We supply a wide array of welding consumables, including E6013, E7018, stainless steel electrodes, and flux-cored wires. Every product undergoes rigorous inspection for coating integrity, tensile strength, and arc stability. These quality standards have positioned us as a preferred welding electrode supplier among professionals seeking both dependability and value.

In addition to performance, we ensure supply chain efficiency. With strong warehousing and global logistics support, we offer timely delivery worldwide. Whether your business is in Southeast Asia, the Middle East, Europe, or South America, we are equipped to meet tight deadlines and large-volume demands.

Advanced Capabilities at Our Welding Rod Factory

Our fully integrated welding rod factory spans over 1,200,000 square meters and is supported by advanced automation and over 500 skilled employees. The facility is designed for both high-capacity production and customized batch manufacturing, allowing us to serve both global brands and regional distributors.

The welding rod factory includes dedicated lines for E6010, E6011, E7016, and specialty electrodes. We use precise control systems during electrode coating, baking, and packaging to ensure product consistency. From core wire selection to finished electrode, each step is monitored for performance and compliance.

Certified with ISO 9001, ISO 14001, and ISO 50001, our operations reflect a commitment to sustainability and quality. Our production standards comply with approvals from ABS, DNV, CCS, LR, and other major classification societies, making our products trusted in critical applications like shipbuilding and pipeline welding.

We welcome factory audits and client visits to foster transparency and trust, and to demonstrate the operational excellence that defines our brand.

Trusted Welding Rod Manufacturing Company with a Global Reach

As a recognized welding rod manufacturing company, we combine innovation with experience to serve global markets under the “GREAT MASTER” brand. We focus on delivering welding solutions that match international specifications, technical needs, and budget considerations.

Our in-house research and development division works continuously to enhance coating chemistry, moisture resistance, arc stability, and welding finish. These advancements allow our welding rod manufacturing company to provide consumables that perform well under different voltage levels, climate conditions, and base materials.

Whether you are sourcing welding materials for structural steel, shipbuilding, boiler repair, or heavy machinery, we offer application-specific electrodes and wires. Our comprehensive service includes not just products, but consultation, certifications, and post-sale support.

More importantly, we remain agile in a fast-changing industry. By maintaining flexibility in product development and delivery, we continue to grow as a reliable welding rod manufacturing company for both existing clients and new partnerships.

Scalable and Efficient Welding Rod Production

Our streamlined welding rod production system ensures that every electrode meets exact standards for usability, safety, and performance. With multiple high-speed production lines, we maintain consistency across product batches, while ensuring a flexible response to custom orders or specialized applications.

Each welding rod production line is fully automated for precise raw material blending, extrusion, drying, and inspection. This results in higher output and lower defect rates. We also maintain traceability from raw input to finished goods, offering transparency and accountability for large and critical orders.

We produce millions of welding electrodes monthly, covering a wide spectrum of electrode types including low hydrogen, stainless steel, rutile, and cellulose rods. All products go through arc testing and metallurgical validation before packaging.

Thanks to our long-term investment in production efficiency and process innovation, we can offer competitive pricing without compromising product integrity. This makes us a preferred partner for global distributors and OEM clients requiring dependable welding rod production.

Experienced Welding Wire Manufacturer for Versatile Applications

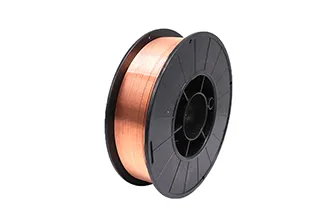

In addition to electrodes, we are also an established welding wire manufacturer providing both solid wires and flux-cored wires (FCAW). Our ER70S-6 welding wire is widely used in automotive, construction, and pressure vessel applications due to its consistent wire feed, minimal spatter, and excellent mechanical properties.

As a welding wire manufacturer, we ensure precise wire drawing and copper coating processes to enhance electrical conductivity and reduce wear on wire feed equipment. This improves the overall efficiency of GMAW (MIG) and SAW (Submerged Arc Welding) operations.

Our flux-cored wires come in gas-shielded and self-shielded varieties, suitable for outdoor fabrication, high deposition rate jobs, and structural welding. Each spool is vacuum-sealed and quality checked to ensure low hydrogen levels and perfect winding.

We also support private labeling and OEM production under customer brands, making us the welding wire manufacturer of choice for businesses looking to expand their product offerings without investing in new infrastructure.

Whether you are sourcing filler metals for general fabrication or precision engineering, our range of welding wires delivers strength, reliability, and smooth operational flow.

welding electrode supplier FAQs

What certifications do you have as a welding electrode supplier?

We hold ISO 9001, ISO 14001, and ISO 50001 certifications. Additionally, our products are approved by ABS, BV, CCS, DNV, LR, NK, KR, RINA, RS, and BKI for marine and industrial use.

What production capacity does your welding rod factory offer?

Our welding rod factory produces millions of electrodes monthly across various lines, including E6013, E7018, and stainless steel types. We can accommodate large-scale and urgent orders efficiently.

Can your welding rod manufacturing company offer OEM services?

Yes, as a flexible welding rod manufacturing company, we provide private labeling and OEM solutions tailored to the branding and packaging needs of our partners worldwide.

What quality controls are used in welding rod production?

Our welding rod production process includes automated coating, controlled drying, real-time inspections, and final arc testing. This ensures each batch meets industry specifications.

What products are available from your welding wire manufacturer operations?

As a full-service welding wire manufacturer, we offer ER70S-6 solid wire, gas-shielded and self-shielded flux-cored wires, and customized options for industrial welding applications.

-

What is a medium-frequency pulse? What types of welding are suitable for?NoticiasNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?NoticiasNov.21,2025

-

Welding Knowledge 6NoticiasNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?NoticiasNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?NoticiasNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016NoticiasNov.17,2025