OEM Welding Electrode Suppliers for High-Quality Welding Solutions and Services

The Importance of OEM SS Welding Electrode Suppliers

In the contemporary manufacturing landscape, the demand for high-quality welding supplies is essential for ensuring robust and reliable production processes. Among these supplies, stainless steel (SS) welding electrodes are critical components, particularly in industries such as construction, automotive, and shipbuilding. Therefore, the role of OEM (Original Equipment Manufacturer) SS welding electrode suppliers cannot be understated. This article explores the significance of these suppliers, the advantages they present, and factors to consider when choosing one.

Understanding OEM SS Welding Electrodes

OEM welding electrodes are manufactured to meet the specific requirements of a company’s production process. These electrodes can come in various grades and specifications, depending on the material being welded and the operating conditions it must endure. SS welding electrodes, in particular, are designed to work with stainless steel, ensuring excellent performance regarding corrosion resistance, durability, and overall integrity of the weld.

Every welding application has unique requirements, and OEM suppliers specialize in creating tailored welding solutions. They leverage advanced manufacturing techniques and strict quality control processes to deliver products that meet precise engineering tolerances.

Advantages of Choosing OEM Suppliers

1. Quality Assurance One of the primary reasons manufacturers choose OEM SS welding electrode suppliers is the consistent quality they provide. OEM suppliers follow stringent quality assurance protocols, ensuring that every electrode produced meets the necessary industry standards. This quality assurance translates into improved welding performance and fewer defects in the final product.

2. Customized Solutions OEM suppliers often work closely with their clients to develop products that fit their specific needs. By offering customized solutions, these suppliers help companies enhance productivity and efficiency. Whether it’s the electrode’s composition, diameter, or coating, factors can be adjusted to fulfill particular welding requirements.

3. Technical Support Established OEM suppliers typically offer robust technical support, guiding clients through various aspects of electrode usage, including proper handling, storage, and welding techniques. This support can significantly aid companies in optimizing their welding processes and troubleshooting issues effectively.

4. Cost-Effectiveness While the initial investment in OEM welding electrodes may be higher than purchasing generic brands, the long-term savings can be substantial. Quality products reduce the risks of weld failures, which can lead to costly repairs and downtime. Additionally, superior performance means less frequent replacements, enhancing overall cost efficiency.

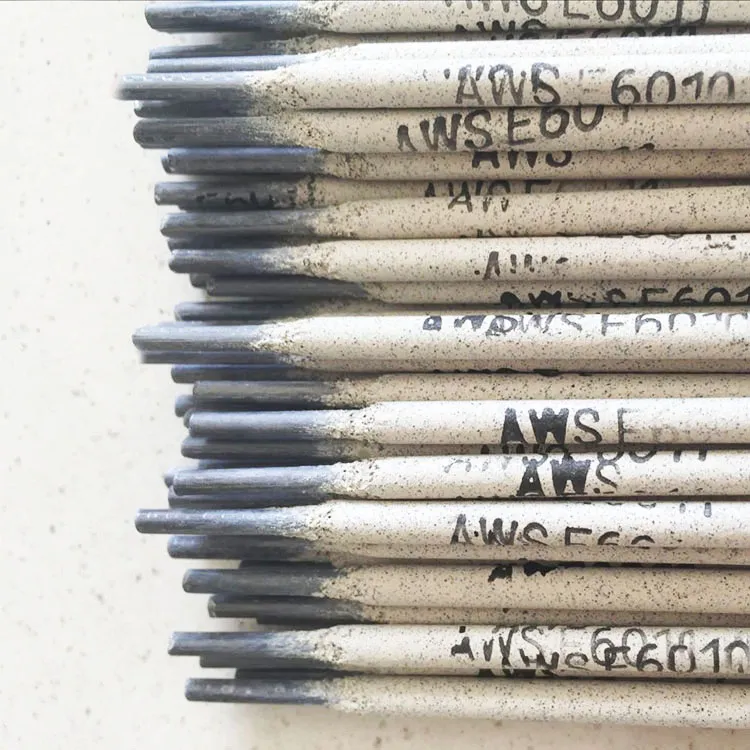

oem ss welding electrode supplier

5. Reliable Supply Chain OEM suppliers usually have well-structured supply chains, which ensure that companies receive their products in a timely manner. This reliability is crucial in maintaining production schedules and avoiding costly delays associated with subpar supply chains.

Factors to Consider When Choosing an OEM Supplier

When selecting an OEM SS welding electrode supplier, several factors should be taken into account

- Industry Experience Consider suppliers with proven experience in the welding electrode sector. Their expertise can lead to better product selection and more informed recommendations.

- Certifications and Compliance Ensure that the supplier holds relevant industry certifications and complies with international quality standards. This compliance is indicative of their commitment to quality and reliability.

- Reputation and Reviews Research the supplier’s reputation within the industry. Customer reviews and testimonials can provide insight into their reliability and product quality.

- After-Sales Support Evaluate the level of after-sales support provided. A supplier who offers comprehensive support can greatly enhance your operational efficiency and address any potential issues swiftly.

Conclusion

OEM SS welding electrode suppliers play a pivotal role in the modern welding industry, providing high-quality, customized solutions that enhance manufacturing processes across various sectors. By understanding the importance of these suppliers and taking the time to choose the right partner, companies can not only improve their welding performance but also achieve greater overall operational efficiency. Investing in quality welding electrodes from reputable OEM suppliers is an essential step toward achieving excellence in manufacturing.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025