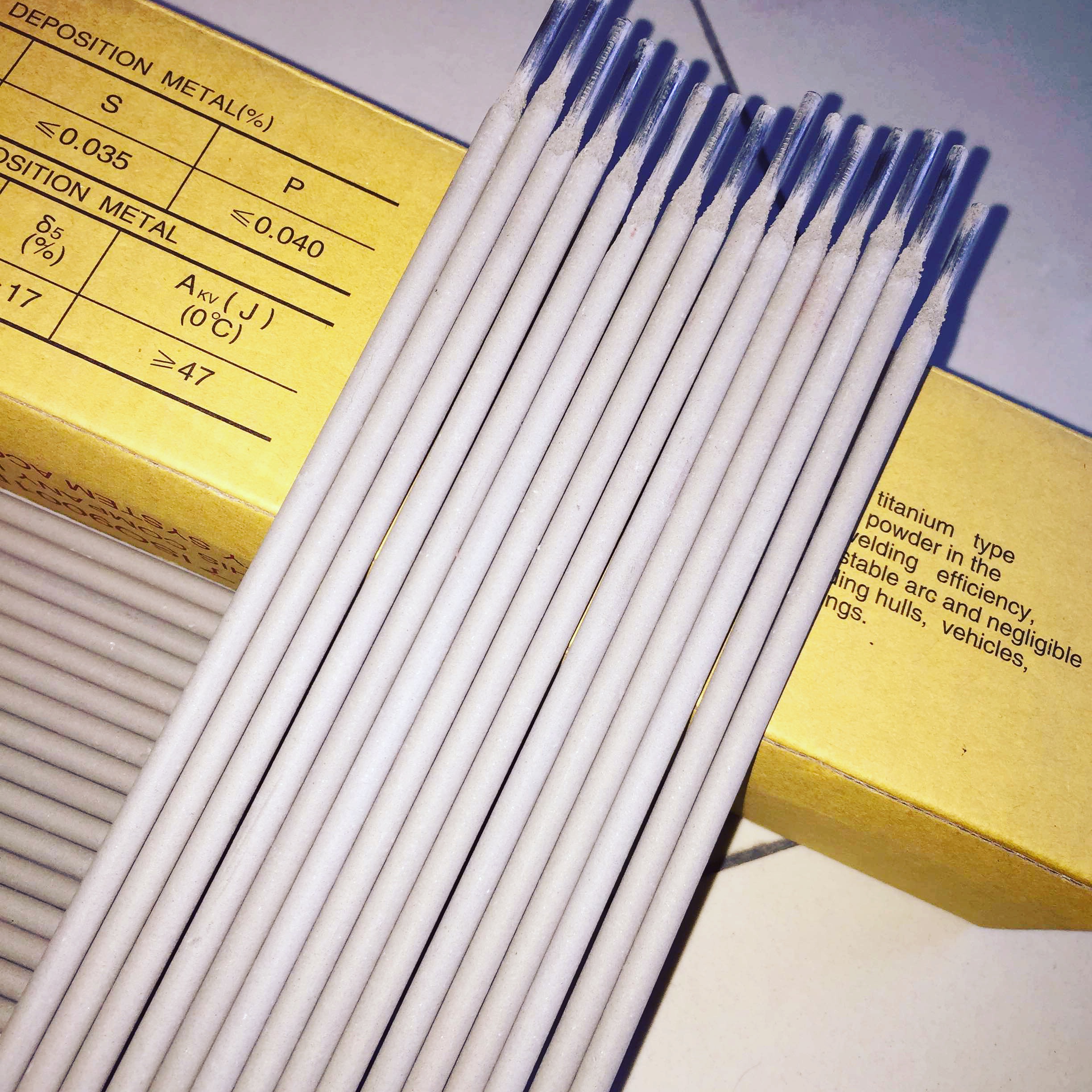

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth Finish

In today's rapidly evolving metal fabrication and engineering sectors, Arc welding electrodes AWS E7024 have emerged as a benchmark for productivity, weld quality, and operational efficiency. SteelToolsChina's solutions are setting new standards as industries demand increasingly stringent mechanical properties, productivity, and certification compliance.

• Industry trend: Global market for welding electrodes is projected to grow at 4.7% CAGR (2024-2028).

• AWS E7024 features: High-deposition rates (up to 200% efficiency), suitable for horizontal/flat fillet welds, and widely adopted in structural steelwork.

• Certifications: Products are manufactured as per ISO 2560, AWS A5.1, and EN ISO 2560-A standards.

1. Industry Trends: The Rise of Arc welding electrodes AWS E7024

As per the Market Research Future analysis, the global usage of rutile high-deposition electrodes like Arc welding electrodes AWS E7024 continues to expand, driven by massive infrastructure and energy projects. Asia-Pacific leads demand due to urbanization, steel construction, and government-backed pipeline projects. Key end-user industries include:

- Structural Steel Fabrication

- Shipbuilding & Marine Platforms

- Petrochemical & Oil/Gas

- Heavy Equipment Manufacturing

- Water Treatment & Municipal Projects

2. Detailed Technical Specifications of Arc welding electrodes AWS E7024

The Arc welding electrodes AWS E7024 are heavily alloyed, iron-powder coated electrodes primarily designed for flat and horizontal fillet welding. Certified under AWS A5.1/A5.1M:2012 and meeting ISO 2560-B-E4624 requirements, E7024 boasts extraordinary deposition rates, low spatter, and excellent bead appearance.

| Parameter | Specification | Standard | Remarks |

|---|---|---|---|

| Diameter | 2.5mm / 3.2mm / 4.0mm / 5.0mm | AWS/ISO | Common range for AWS E7024 |

| Length | 350mm / 400mm / 450mm | AWS/ISO | Adjustable per application |

| Current Type | AC/DC(+VE) | AWS A5.1 | Versatile compatibility |

| Deposition Rate | ~145% (up to 210% on heavy iron-powder grade) | ISO 2560 | Rapid, high productivity |

| Tensile Strength | ≥ 490 MPa (≥ 70,000 PSI) | AWS A5.1 | High mechanical strength |

| Yield Strength | ≥ 400 MPa | ISO 2560 | Meets prominent industry norms |

| Elongation | ≥ 20% | ISO 2560 | Ductile, impact-resistant |

| Impact Toughness | ≥ 47 J @ 0°C | ISO 2560 | Good at low-temp service |

| Chemical Composition: C, Mn, Si, S, P | 0.08, 1.30, 0.50, 0.022, 0.025 (%) | ISO 2560 | Typical E7024 balance |

| Coating Type | Rutile-Iron Powder | — | For smooth arc & high deposit |

| Manufacturing Tolerance | ±0.02mm (Dia.), ±1.5mm (Length) | ANSI/ISO | Precision-verified |

3. Manufacturing Process Flow of Arc welding electrodes AWS E7024

- Raw Material Selection → (Certified steel rods; powder conforming to ISO 14174)

- Core Wire Cleaning & Cutting → (Removes oil/dirt, precise cut)

- Mixing of Coating Powders → (Rutile, iron powder, SiO2, special binders)

- Extrusion/Coating Process → (Automatic/robotic press; even distribution)

- Drying & Pre-bake → (150–180°C, 2-4h; eliminates moisture)

- CNC Chamfering → (Uniform arc strike tip)

- Final Baking → (350°C, 1.5h)

- Quality Inspection (ISO/ANSI) → (Dimensions, coating adhesion, mechanical testing)

- Packing & Shipping

4. Technology Advantages of Arc welding electrodes AWS E7024

- Exceptional Deposition Rate: Iron-powder rich flux layer yields 2x-2.1x the metal per unit time vs. general E6013, reducing labor costs and arc-time by up to 38% (see AWS Welding Journal, 2020).

- Consistent Penetration: Targeted for thicker base metals (6–20 mm) in structural welding.

- Superb Arc Stability: Smooth bead and minimum spatter, simplifying post-weld cleaning.

- Certified Quality: Each lot is tested for X-ray, macro, bend and impact— documentation provided on request.

- Anti-corrosive Bead: Specialized for outdoor steelwork prone to humidity/rust.

- Energy Efficient: Can be paired with medium-power AC/DC machines, saving up to 11% energy per ton weld (per EN ISO 2560 comparison).

5. Supplier Comparison Table: Choosing the Right Arc welding electrodes AWS E7024 Partner

| Supplier Name | Country | AWS E7024 Cert. | ISO/EN Cert. | Deposition Efficiency (%) | Custom Diameters | After-Sales Service |

|---|---|---|---|---|---|---|

| SteelToolsChina | China | Yes | Yes | 200–210 | 2.5–5.0mm | 24/7, Full support, OEM |

| Bohler Welding | Austria | Yes | Yes | 190 | 3.2–5.0mm | Business hours |

| ESAB | Sweden | Yes | Yes | 190 | 3.2–4.0mm | Business hours |

| Kobelco | Japan | Yes | Partial | 185 | 2.6–5.0mm | Business hours, Online consult |

6. Customization & Turnkey Solutions

- Custom Specifications: Adjustable electrode diameter (2.5, 3.2, 4.0, 5.0mm), length, and coating thickness per application/project requirement.

- OEM Branding: Private labeling, packaging design, and laser marking.

- Bulk Packaging: Anti-moisture, seaworthy, export-compliant, palletized delivery available—short lead time (usually 12–18 working days for full-container111 order).

- Full Documentation: MTC, ISO, AWS, SGS/BV certificates, with third-party inspection by client request.

- Traceability: All batches logged by unique heat numbers per ISO 3834 QMS.

7. Application Cases & Client Feedback

Scope: 45km of urban gas trunk pipeline, DN700, X42-grade.

Challenge: High humidity and tight schedule.

Solution: AWS E7024 by SteelToolsChina; results: 28% reduction in weld time, flawless radiographic integrity.

Client Feedback: "Switching to Arc welding electrodes AWS E7024 cut our work hours drastically and the welds sailed through all NDT checks."

Deployed E7024 (4.0mm) for flat butt and T-joint deck welding. Achieved bead widths to spec, minimal post-weld cleaning, high productivity for 800+ tons steel.

Certified per: DNV-GL & ISO 2560-1

8. Technical Data Visualization: Deposition Rate Comparison

9. FAQs – Deep Technical Dive Into Arc welding electrodes AWS E7024

10. Delivery, Quality Assurance & Customer Service

- Lead Time: Most orders (OEM-supported) shipped in 12–18 working days. Urgent/expedited available.

- Warranty: 18-month replacement or refund guarantee for any welding defect attributable to manufacturing.

- Customer Support: 24/7 multi-language team; remote technical guidance (including welding parameter optimization, on-site troubleshooting).

- Documentation: AWS, ISO, SGS, MTC, and application-specific certificates supplied digitally and in hard copy.

- Secure Packaging: Vacuum inner pack, moisture barrier, export-oriented pallets, unique batch codes, and shipping marks for traceability.

11. References, Further Reading & Authority Links

- • AWS A5.1: Specification for Carbon Steel Electrodes

- • ISO 2560: Welding consumables – Covered electrodes for manual metal arc welding of non-alloy/ fine grain steels

- • Welding Web Forum: AWS E7024 Experiences & Advice

- • SteelToolsChina—Arc welding electrodes AWS E7024 Specification

- • Lincoln Electric: Deposition Data Sheet – Covered Electrodes

- •

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025