AWS E6010 Welding Rods – Deep Penetration, Pipe-Ready

Aws E6010 Welding Rods is a key solution in the manufacturing industry, specifically within Fabricated metal products and Welding material manufacturing. This article explores how HEBEI YUJINHONG TECHNOLOGY CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Aws E6010 Welding Rods Overview

- Benefits & Use Cases of Aws E6010 Welding Rods in Welding material manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Aws E6010 Welding Rods from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

Aws E6010 Welding Rods Overview

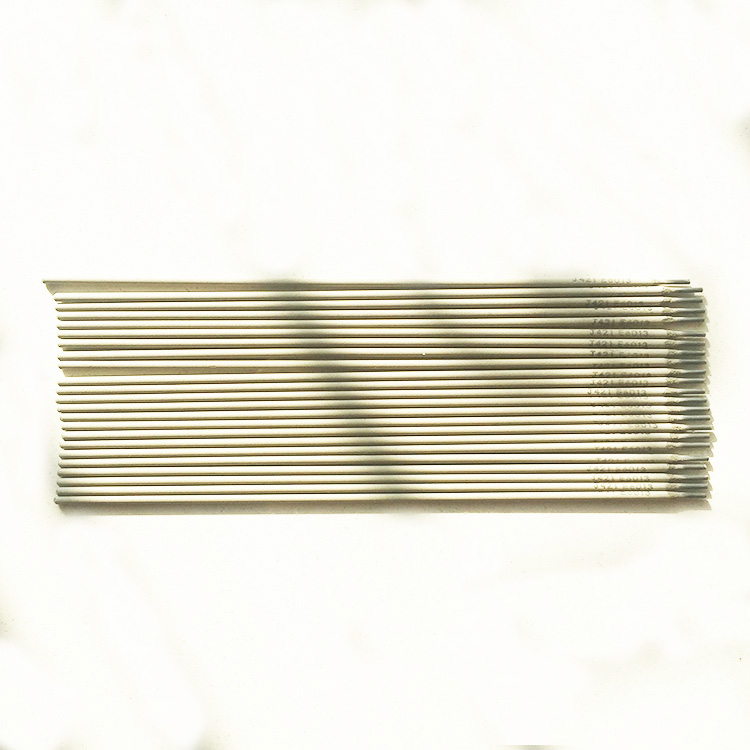

Aws E6010 Welding Rods are cellulosic-coated, all-position SMAW electrodes engineered for deep penetration and a forceful, fast-freezing arc—ideal for open-root passes on carbon steel pipe, field fabrication, and maintenance. Classified under AWS A5.1 as E6010 (also searched as “aws a5 1 e6010” and “aws e6010 electrode”), they are typically used on DCEP (electrode positive) and deliver consistent weld quality even on steel with light rust, mill scale, or tight fit-ups. Typical mechanical properties meet 60 ksi minimum tensile strength, with excellent ductility and dependable impact performance in common service environments.

Common diameters include 2.5 mm, 3.2 mm, and 4.0 mm, supporting a wide amperage window for shop or field conditions—for example, 3.2 mm often runs around 75–130 A depending on joint, position, and machine. The fast-freeze slag system stabilizes the puddle for vertical and overhead welding, while the penetrating arc delivers strong, defect-resistant roots that tie in reliably. For B2B buyers seeking predictable performance, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. manufactures E6010 electrodes with rigorous coating control, batch traceability, and consistent arc chemistry, helping fabricators standardize procedures and reduce variability across projects.

Benefits & Use Cases of Aws E6010 Welding Rods in Welding material manufacturing

In Welding material manufacturing and fabricated metal products, Aws E6010 Welding Rods shine in applications such as pipeline root passes, plant piping tie-ins, storage tank construction, field erection of structural steel, and general repair. Their deep penetration and fast-freeze characteristics make them the go-to for open-root pipe joints, vertical-down pipeline work, and out-of-position structural repairs where productivity and defect resistance (lack of fusion, suck-back) are paramount. E6010 is also frequently paired with low-hydrogen fill and cap passes (e.g., E7018) to combine speed with code-quality finishes.

Competitive advantages include: stable ignition and re-strike, robust arc force for gap-bridging, strong penetration through light surface contaminants, and easy slag removal that shortens post-weld clean-up. For OEMs and contractors standardizing procedures across crews and shifts, HEBEI YUJINHONG TECHNOLOGY CO.,LTD. provides application support (parameter windows, best practices for root reinforcement, fit-up tolerance guidance) and consistent lot-to-lot quality. That reliability helps QA teams maintain radiographic acceptance on critical welds while helping operations leaders hit throughput and schedule milestones without compromising safety or compliance.

Cost, Maintenance & User Experience

Total cost of ownership for Aws E6010 Welding Rods is driven by labor productivity and reduced rework. The penetrating, fast-freeze arc enables quicker travel speeds and dependable tie-in on root passes, often cutting fit-up sensitivity and minimizing back-gouging or repair cycles. Less time spent on joint cleaning and post-weld grinding translates directly into labor savings, while broad compatibility with engine-driven and transformer machines helps contractors maximize existing fleet utilization. Over the life of a project, these factors typically deliver a favorable ROI compared to slower, more preparation-intensive alternatives.

Maintenance and handling are straightforward: store rods dry in their original packaging, protect from excessive humidity, and rotate stock (first-in, first-out). Unlike low-hydrogen electrodes, E6010 generally does not require high-temperature rebaking; simply keep packages sealed until use and avoid moisture exposure. Feedback from fabricators and pipeline contractors indicates consistent arc starts, low spatter, and reliable x-ray acceptance on open-root welds. Many users report fewer defects in vertical and overhead work, contributing to predictable schedules and lower total project cost in the Fabricated metal products sector.

Sustainability & Market Trends in manufacturing

Global infrastructure upgrades, energy transition pipelines, municipal water systems, and industrial maintenance are fueling demand for dependable stick welding solutions. Within these growth cycles, sustainability and compliance are increasingly important. E6010’s ability to deliver first-pass quality and minimize rework helps reduce consumable waste, grinding, and energy use at the jobsite. On the regulatory side, adherence to recognized standards—such as AWS A5.1 for E6010—supports consistent qualification and documentation, easing audit pressure for EPCs and large fabricators.

HEBEI YUJINHONG TECHNOLOGY CO.,LTD. aligns with these trends by focusing on process efficiency, responsible sourcing, and packaging that prioritizes protection and recyclability. The company continuously refines coating formulations and production controls to stabilize arc characteristics, reduce variability, and help customers lower their carbon footprint through fewer defects and higher first-pass yields. For B2B decision makers seeking reliable supply, technical consistency, and forward-looking manufacturing practices, this approach supports both operational excellence and ESG objectives.

Conclusion on Aws E6010 Welding Rods from HEBEI YUJINHONG TECHNOLOGY CO.,LTD.

In manufacturing, fabricated metal products, and welding material manufacturing, Aws E6010 Welding Rods deliver the productivity, penetration, and out-of-position control that projects demand—especially for open-root pipe and field fabrication. Backed by the dependable quality of HEBEI YUJINHONG TECHNOLOGY CO.,LTD., these electrodes help teams achieve consistent first-pass results and lower total project cost. Ready to specify or trial E6010 in your next procedure?

- Contact us: email: info@steeltoolschina.com

- Visit our website: https://www.steeltoolschina.com

-

What is a medium-frequency pulse? What types of welding are suitable for?VijestiNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?VijestiNov.21,2025

-

Welding Knowledge 6VijestiNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?VijestiNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?VijestiNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016VijestiNov.17,2025