Welding Steel Rod in Automotive with E7016 Electrodes

The automotive industry relies heavily on precision and durability, especially when it comes to structural components like steel rods. Welding steel rod is a critical process in manufacturing vehicles, ensuring frames, chassis, and other parts withstand stress and wear. Central to this process are welding electrodes, which act as the conduit for creating strong, reliable joints. Among the various options, E7016 electrodes have emerged as a preferred choice for professionals. This article explores the nuances of using E7016 electrodes for welding steel rod in automotive applications, delves into the types of electrode used in welding, and answers common questions to guide your next project.

Understanding Welding Electrodes and Their Role in Automotive Applications

Welding electrodes are consumable rods or wires that generate an electric arc to melt and fuse metals. In automotive manufacturing, they play a pivotal role in joining welding steel rod components, which form the backbone of a vehicle’s structure. The E7016 electrode, classified under the American Welding Society (AWS) system, is a low-hydrogen, iron-powder-coated rod designed for DC welding. Its unique composition minimizes porosity and cracking, making it ideal for high-stress automotive environments.

The automotive sector demands welds that can endure vibrations, temperature fluctuations, and mechanical loads. E7016 electrodes excel here due to their deep penetration and smooth arc stability. Unlike standard electrodes, E7016’s low-hydrogen coating reduces the risk of hydrogen-induced cracking, a common issue when welding steel rod with higher carbon content. This makes them indispensable for critical joints in axles, suspension systems, and engine mounts.

Choosing the right welding electrodes also depends on the base metal’s properties. Automotive-grade steel rods often have specific alloy compositions, and E7016 electrodes are compatible with low-to-medium carbon steels, ensuring seamless integration. Their versatility extends to overhead and vertical welding positions, which are common in complex automotive assemblies.

Mastering the Art of Welding Steel Rod in Automotive Manufacturing

Welding steel rod requires a blend of skill, precision, and the right tools. In automotive contexts, the stakes are high: a weak weld can compromise vehicle safety. E7016 electrodes simplify this process by offering consistent performance, even on thick or irregularly shaped steel rods.

Key Techniques for Success

Pre-Weld Preparation: Clean the welding steel rod surfaces thoroughly to remove rust, oil, or debris. Contaminants can weaken the weld, leading to failures.

Current Settings: E7016 electrodes perform best with DC reverse polarity (electrode positive). Adjust amperage based on the rod’s thickness—typically 90–130 amps for 3.2mm electrodes.

Arc Length and Angle: Maintain a short arc length (2–3mm) and a 70–80° work angle to ensure proper penetration and slag formation.

E7016’s fast-freezing slag allows for multi-pass welding, essential for thick automotive components. Its ability to handle slight impurities in the base metal also reduces rework, saving time and costs.

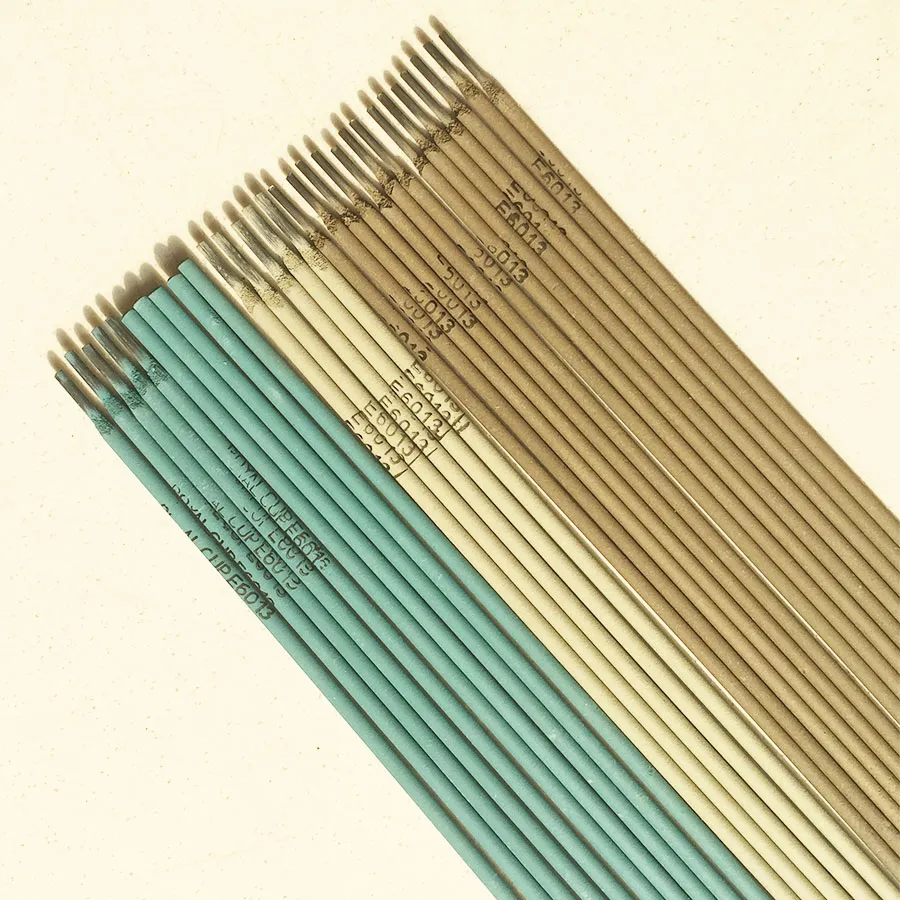

Exploring the Types of Electrode Used in Welding: Spotlight on E7016

The types of electrode used in welding vary based on coating, current compatibility, and application. E7016 falls under the “low-hydrogen” category, but understanding its peers highlights why it’s a standout choice for automotive welding steel rod projects.

Common Electrode Types

E6010: Deep penetration but AC-incompatible; suited for dirty or rusty metals.

E7018: Similar to E7016 but requires strict storage to prevent moisture absorption.

E6013: General-purpose with easy slag removal, ideal for thin materials.

E7016 electrodes bridge the gap between E6010’s penetration and E7018’s strength. Their iron powder coating enhances deposition rates, making them efficient for large-scale automotive production. Unlike E7018, they tolerate minor moisture exposure, reducing pre-weld drying time.

For welding steel rod in automotive frames, E7016’s balanced properties ensure strong, ductile joints that resist fatigue—a non-negotiable trait for vehicles navigating rough terrains

FAQs About Welding Electrodes, Welding Steel Rod, and Types of Electrode Used in Welding

What Advantages Do E7016 Welding Electrodes Offer for Automotive Projects?

E7016 electrodes provide deep penetration, low hydrogen levels, and compatibility with DC power. These traits minimize cracking and ensure durable welds on welding steel rod components, which are vital for vehicle safety.

Can E7016 Electrodes Be Used for All Types of Electrode Used in Welding Applications?

While E7016 excels in low-carbon steel welding, it’s not suitable for non-ferrous metals like aluminum. Stick to automotive-grade steel rods for optimal results.

How Does Welding Steel Rod with E7016 Improve Production Efficiency?

The fast deposition rate and easy slag removal of E7016 reduce welding time and post-weld cleanup. This speeds up assembly lines without compromising quality.

Are E7016 Welding Electrodes Prone to Moisture Damage?

While they’re low-hydrogen, E7016 electrodes still require dry storage. However, they’re less sensitive than E7018, making them practical for busy workshops.

Why Choose E7016 Over Other Types of Electrode Used in Welding for Automotive Steel?

E7016 balances penetration, strength, and ease of use. Its adaptability to vertical welding and tolerance for minor impurities make it a go-to for complex automotive frames.

In the demanding world of automotive manufacturing, the right welding electrodes can make or break a project. E7016 stands out as a reliable, efficient choice for welding steel rod, offering durability and ease of use. By understanding the types of electrode used in welding and their applications, professionals can ensure safer, longer-lasting vehicles. Whether you’re crafting a chassis or repairing suspension parts, E7016 electrodes deliver the precision and strength that modern automotive engineering demands.

-

What is a medium-frequency pulse? What types of welding are suitable for?VijestiNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?VijestiNov.21,2025

-

Welding Knowledge 6VijestiNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?VijestiNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?VijestiNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016VijestiNov.17,2025