0.9mm MIG Wire Selection for Optimal Welding Performance and Quality

The Versatility and Applications of 0.9mm MIG Wire

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), is a widely used welding technique that employs a continuous wire feed to create an arc between the welding wire and the workpiece. One of the most common diameters of MIG wire is 0.9mm, which offers a balance between penetration and ease of use, making it a popular choice among both novice and experienced welders. This article will explore the versatility and applications of 0.9mm MIG wire, highlighting its benefits and considerations for various welding projects.

Composition and Characteristics

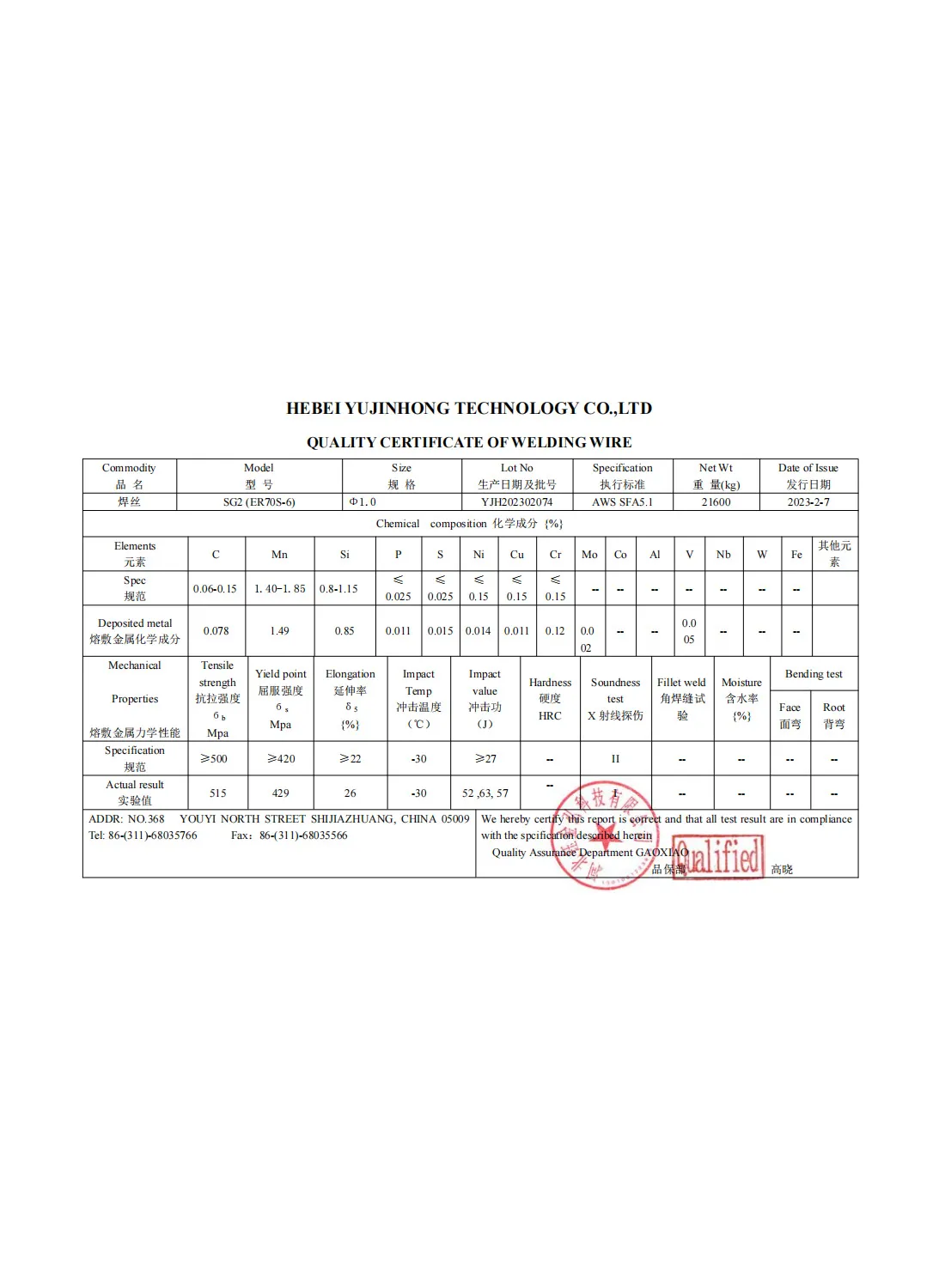

0.9mm MIG wire is typically made from materials such as ER70S-6, a type of carbon steel wire that is commonly used for welding mild and low alloy steels. This wire is characterized by its excellent weldability and is designed to produce high-quality welds with good mechanical properties. The smaller diameter of 0.9mm allows for precision in welding thin materials, while also providing sufficient strength for thicker sections. Moreover, the wire is often copper-coated to enhance conductivity and prevent oxidation, ensuring a smooth feeding process and consistent arc stability.

Ideal Applications

The 0.9mm MIG wire is ideal for a variety of applications, particularly in industries such as automotive, manufacturing, and construction. For thin materials, such as sheet metal and automotive components, 0.9mm wire allows for a controlled welding process that minimizes the risk of burn-through and distortion. This is crucial in applications where precision and aesthetics matter.

In manufacturing contexts, this wire diameter is advantageous for fabricating components and structures that require thorough penetration without excessive buildup. This becomes especially important in situations where the integrity of the weld joint is critical, such as in pressure vessels or structural steelwork.

Additionally, 0.9mm MIG wire is increasingly being utilized in home workshops and hobby projects, as it is compatible with standard hobbyist-grade MIG welders. This accessibility encourages DIY enthusiasts to explore metal fabrication, repair, and artistic metalworking projects.

0.9mm mig wire

Benefits of Using 0.9mm MIG Wire

One of the primary benefits of using 0.9mm MIG wire is its ease of use. The smaller diameter ensures a more manageable arc, reducing the likelihood of overheating and allowing for better control during the welding process. This characteristic makes it an excellent choice for beginners who may still be mastering their welding skills.

Another advantage is the versatility of this wire size across different metal types. It can be used for welding not just steel, but also stainless steel and aluminum when paired with the appropriate shielding gas and setup. This flexibility allows welders to handle a range of materials without needing to frequently change their equipment.

Considerations

While the 0.9mm MIG wire is beneficial in many scenarios, it is essential to consider the specific requirements of your welding project. For instance, when dealing with thicker metals or heavy-duty welding tasks, a larger diameter wire may be more appropriate to ensure adequate heat input and penetration. Additionally, the choice of shielding gas, welding speed, and travel angle will influence the quality of the weld, necessitating careful adjustment to achieve optimal results.

Conclusion

In summary, 0.9mm MIG wire is a versatile and widely used option in the welding industry, suited for both professional and amateur applications. Its characteristics make it ideal for welding thin materials while maintaining strength and quality in the joints. As welding technology continues to advance, the relevance of this wire size will likely endure, empowering welders to tackle diverse metalworking challenges effectively. Whether in automotive repair, manufacturing, or artistic ventures, the 0.9mm MIG wire remains a valuable asset in the toolkit of any welder.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025