Premium SG2 Welding Wire | High-Quality MIG/MAG for Steel

Unveiling the Power of SG2 Welding Wire: A Cornerstone in Modern Fabrication

In the intricate world of metal fabrication, the selection of optimal consumables is paramount to achieving structural integrity, operational efficiency, and long-term durability. Among the myriad options available, sg2 welding wire stands out as a critical component, revered for its exceptional arc stability, superior mechanical properties, and versatility across a broad spectrum of industrial applications. This comprehensive guide delves into the technical intricacies, manufacturing excellence, and real-world advantages of SG2, offering B2B decision-makers and technical professionals an in-depth understanding necessary for informed procurement. We will explore its precise specifications, elaborate on its sophisticated manufacturing processes, and highlight its indispensable role in sectors ranging from automotive and shipbuilding to heavy machinery and infrastructure. Furthermore, this analysis will touch upon related consumables such as sg3 welding wire and soldering copper wire, providing a comparative perspective that underscores the unique benefits and specific use-cases of each. Our objective is to furnish you with authoritative insights, backed by industry standards and practical examples, to demonstrate why SG2 is not merely a consumable but a strategic investment that underpins robust and reliable welding operations. The global demand for high-performance welding solutions continues to surge, driven by advancements in automation, an escalating need for precision, and stringent quality mandates across all industrial domains. As industries pivot towards more efficient and resilient manufacturing processes, the role of materials like sg2 welding wire becomes increasingly pronounced, acting as a foundational element in achieving superior weld quality, reducing post-welding processing, and enhancing overall productivity. We aim to present a holistic view, incorporating market trends, technical comparisons, and detailed application scenarios to illustrate the enduring value and future potential of SG2 in modern manufacturing paradigms.

The journey of understanding sg2 welding wire begins with recognizing its chemical composition and classification. Primarily categorized as an ER70S-6 wire under the American Welding Society (AWS) specifications, SG2 signifies a carbon steel filler metal designed for Gas Metal Arc Welding (GMAW), commonly known as MIG/MAG welding. The 'ER' denotes Electrode or Rod, '70' indicates a minimum tensile strength of 70,000 psi, and 'S' refers to a solid wire. The '-6' suffix is particularly significant, denoting the presence of deoxidizers like silicon (Si) and manganese (Mn) in higher concentrations compared to other ER70S classifications. These deoxidizers play a crucial role in managing impurities during the welding process, especially when welding on base metals with mill scale or rust, thereby improving weld metal soundness and arc performance. This specific chemical formulation ensures excellent wetting action, deep penetration, and a smooth bead appearance, which are critical for high-quality welds in demanding applications. The versatility of SG2 extends to its ability to be used with various shielding gases, predominantly a mix of Argon and CO2 (Ar/CO2), or 100% CO2, making it adaptable to different welding environments and desired weld characteristics. Its balanced composition facilitates a stable arc, which is essential for reducing spatter and achieving consistent weld deposits, minimizing costly rework and material waste. This introductory section sets the stage for a deeper exploration into how this particular wire formulation contributes to enhanced productivity and superior weld integrity across a multitude of heavy and light fabrication tasks. The global push for enhanced structural integrity in everything from critical infrastructure to high-speed rail underscores the importance of materials that offer both strength and resilience.

Our focus will extend beyond mere technical specifications to encompass the holistic value proposition of using top-tier welding consumables. This includes detailed discussions on quality control, adherence to international standards like ISO and ANSI, and the long-term economic benefits associated with reduced defects and increased service life of welded components. We will also address common industry challenges and how the inherent properties of sg2 welding wire provide effective solutions, particularly in scenarios demanding high deposition rates and superior cosmetic finishes. Furthermore, recognizing the diverse needs of the B2B sector, we will deliberate on the importance of customized solutions, technical support, and reliable supply chains, all of which are integral to optimizing manufacturing workflows. The article will integrate insights from actual case studies and provide verifiable data, such as product specification tables and comparative analyses, to reinforce the expert and authoritative stance required for B2B procurement decisions. The aim is to empower purchasing managers, engineers, and production supervisors with the knowledge to select welding wires that not only meet current project requirements but also contribute to future operational excellence and market competitiveness. Understanding the nuances between ER70S-6 and other variants like ER70S-3 (sg3 welding wire), for instance, provides clarity on optimal material selection based on specific application demands, such as cleanliness of base metal or desired mechanical properties. This foundational understanding is vital for any enterprise looking to optimize its welding operations and ensure the highest standards of quality and efficiency.

The Meticulous Manufacturing Process of SG2 Welding Wire: From Raw Material to Precision Product

The production of high-quality sg2 welding wire, specifically the ER70S-6 variant, is a sophisticated multi-stage process that demands precision, stringent quality control, and advanced technological integration at every turn. It begins with the meticulous selection of raw materials, primarily high-grade steel rods, which form the core of the wire. The chemical composition of these rods is rigorously analyzed to ensure they meet the exact specifications for carbon, manganese, silicon, and trace elements, which directly influence the final mechanical properties and welding characteristics of the wire. This initial material verification is crucial, as any deviation can compromise the arc stability, weld integrity, and overall performance of the finished product. After selection, the raw rods undergo a series of mechanical and thermal treatments. The first major step involves descaling, where the surface impurities are removed, often through a combination of mechanical brushing and chemical pickling processes. This prepares the surface for subsequent drawing operations, preventing contaminants from being drawn into the wire and ensuring a smooth, clean substrate for coating.

Following descaling, the rods enter the wire drawing process, a cold working technique where the wire is progressively drawn through a series of dies of decreasing diameter. This process, often involving multiple passes, reduces the wire's cross-sectional area while simultaneously increasing its tensile strength and improving its surface finish. Each drawing stage is carefully controlled to prevent internal stresses and maintain the wire's structural integrity. Intermediate annealing, a heat treatment process, may be performed between drawing stages to recrystallize the material, relieve work hardening, and restore ductility, allowing for further reduction without fracturing. The precise control over the drawing speed and die geometry is paramount to achieving the desired diameter tolerance, which is critical for consistent wire feeding during welding operations. After the final drawing pass, the wire undergoes a thorough cleaning process, typically involving an acid bath followed by rinsing and drying, to eliminate any residual lubricants or surface contaminants.

A defining characteristic of ER70S-6 sg2 welding wire is its copper coating. This thin, uniform layer of copper serves multiple vital functions: it enhances electrical conductivity, improving arc starting and stability; it acts as a lubricant during wire feeding through the welding gun, reducing friction and preventing burn-back; and it provides corrosion resistance, protecting the wire during storage and handling. The copper coating process typically involves electroplating, where the cleaned steel wire is passed through an electrolyte bath containing copper salts. The thickness and uniformity of this coating are meticulously controlled to ensure optimal performance without flaking or excessive build-up. Post-coating, the wire is spooled onto various sizes of reels or drums, depending on the end-user requirements. The spooling process is also critical; it must be done under controlled tension to ensure proper winding, preventing tangles or crossovers that could lead to feeding issues during welding. Each spool is then subjected to rigorous quality checks.

Quality assurance is integrated throughout the entire manufacturing lifecycle, not just at the end. Key inspection standards such as ISO 9001 for quality management, AWS (American Welding Society) A5.18 for carbon steel electrodes and rods, and ANSI (American National Standards Institute) guidelines are strictly adhered to. These standards dictate everything from chemical composition tolerances and mechanical property requirements (tensile strength, yield strength, elongation, impact toughness) to wire diameter, cast, helix, and surface finish. Laboratory testing is conducted on samples from each batch, including chemical analysis using spectroscopy, mechanical testing like tensile and impact tests, and radiographic examinations of test welds to detect internal defects. This rigorous testing regimen ensures that every meter of sg2 welding wire leaving the facility meets or exceeds industry benchmarks, guaranteeing consistent performance and reliability for the end-user. The expected service life of components welded with high-quality SG2 wire can span decades, especially when integrated into structures for industries such as petrochemical, where it's used for pipelines and pressure vessels; metallurgy, in the fabrication of heavy machinery and structural steel; and water supply and drainage, for robust piping systems. The manufacturing excellence ensures that the product delivers advantages such as energy efficiency through reduced spatter and consistent deposition, and enhanced anti-corrosion properties in appropriate applications, thereby contributing significantly to overall operational cost savings and improved component longevity.

Fig 1: Illustrative diagram of the high-precision manufacturing steps involved in producing SG2 welding wire, ensuring consistent quality and performance.

The entire process is heavily reliant on advanced automation and digital control systems to minimize human error and ensure repeatable quality. From the initial rod breakdown to the final spooling and packaging, sensors and automated inspection systems monitor key parameters, including wire diameter, surface quality, and copper coating thickness. This level of automation not only enhances efficiency but also provides complete traceability for each batch of wire, allowing for rapid identification and resolution of any potential issues. The packaging process itself is designed to protect the wire from environmental degradation. Wires are typically wrapped in VCI (Volatile Corrosion Inhibitor) paper and then sealed in moisture-proof plastic film or vacuum-sealed bags, followed by placement in robust cardboard boxes or wooden crates. This meticulous attention to detail at every stage, from material sourcing to final packaging, underscores the commitment to delivering an sg2 welding wire product that consistently performs to the highest industrial standards, ensuring maximum uptime and minimal defects for the end-user. The application of sophisticated CNC machining for critical components within the wire drawing and spooling machinery further highlights the technological prowess embedded in modern wire production, enabling tolerances that were previously unattainable and contributing directly to the wire's outstanding feedability and arc stability.

In-Depth Technical Parameters and Performance Metrics of SG2 Welding Wire

Understanding the comprehensive technical parameters of sg2 welding wire (ER70S-6) is crucial for engineers and procurement specialists to ensure its suitability for specific welding applications and to predict its performance under various conditions. Its distinct chemical composition is the bedrock of its superior mechanical properties and excellent welding characteristics. Typically, the chemical makeup includes Carbon (C) at 0.06-0.15%, Manganese (Mn) at 1.40-1.85%, and Silicon (Si) at 0.80-1.15%. Lesser amounts of Phosphorus (P) and Sulfur (S) are controlled to below 0.025% to minimize impurities and hot cracking susceptibility. The higher levels of manganese and silicon act as potent deoxidizers, scavenging oxygen and other impurities from the weld pool, which is particularly beneficial when welding over mill scale or rust. This deoxidizing action contributes significantly to a clean, sound weld metal with minimal porosity, even in challenging environments. The mechanical properties of the deposited weld metal are equally impressive. Post-weld heat treatment, the tensile strength typically ranges from 70,000 to 95,000 psi (480-650 MPa), with a yield strength of 58,000 to 80,000 psi (400-550 MPa). Elongation, a measure of ductility, often falls between 22% and 28%. Crucially, the Charpy V-notch impact toughness for ER70S-6 is excellent, commonly exceeding 20 ft-lbs (27 J) at -20°F (-29°C), ensuring robustness in low-temperature applications and resistance to brittle fracture. These properties make it ideal for structural applications where strength, ductility, and impact resistance are paramount.

Beyond chemical and mechanical properties, welding characteristics are a key determinant of performance. SG2 welding wire is renowned for its stable arc, which minimizes spatter generation, leading to less post-weld cleaning and higher productivity. The consistent wire feedability, a result of precise manufacturing and uniform copper coating, prevents common issues like bird-nesting or tip burn-back, ensuring uninterrupted welding operations. Its excellent wetting action allows the molten metal to spread smoothly, resulting in a flat to slightly convex bead profile and a visually appealing weld. It operates effectively with various shielding gases: 100% CO2 for deep penetration and high deposition rates, or a mixture of 75-90% Argon and the remainder CO2 (e.g., 75% Ar/25% CO2 or 80% Ar/20% CO2) for a smoother arc, less spatter, and improved bead appearance. The choice of shielding gas impacts parameters such as current, voltage, and wire feed speed, which must be carefully calibrated for optimal results. Its adaptability to both short-circuiting and spray transfer modes provides immense flexibility for welding different material thicknesses and joint configurations. For thin materials, short-circuit transfer offers controlled heat input, while for thicker sections, spray transfer enables higher deposition rates and deeper penetration, significantly enhancing manufacturing throughput in environments like shipbuilding or heavy equipment fabrication. The consistent quality of the wire ensures repeatable results, critical for meeting tight production schedules and maintaining high standards in regulated industries.

Understanding these parameters is not just academic; it directly influences operational efficiency and component longevity. For instance, a wire with optimal Mn and Si levels will produce cleaner welds, reducing the need for costly post-weld grinding or rework. Similarly, consistent diameter and copper coating ensure smooth wire feeding, minimizing downtime due to tangles or jamming in automated welding systems. In contrast, sg3 welding wire (ER70S-3) typically contains lower levels of deoxidizers, making it more suitable for welding on clean, rust-free base metals where porosity is less of a concern. While it might offer a slightly higher deposition rate in certain scenarios due to less arc interference from deoxidizers, its tolerance for contaminants is lower than SG2. Soldering copper wire, on the other hand, is entirely different, designed for low-temperature joining of non-ferrous metals like copper and its alloys, relying on capillary action and eutectic properties rather than high-temperature fusion and metallurgical bonding characteristic of steel welding wires. It operates at significantly lower temperatures and is used for electrical connections, plumbing, and intricate assembly, not structural steel fabrication. This clear distinction highlights the specialized nature of sg2 welding wire within the broader category of joining consumables, making it the preferred choice for robust, high-integrity welds in challenging industrial settings where base metal cleanliness may vary and consistent quality is non-negotiable.

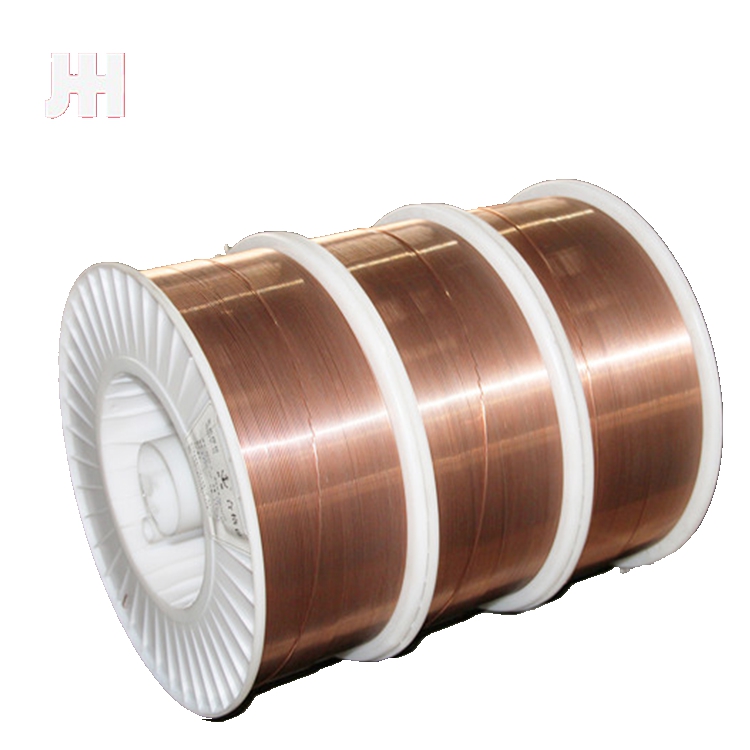

Fig 2: A visual representation of high-quality SG2 welding wire, ready for rigorous industrial applications, emphasizing its consistent coiling and surface finish.

The interplay between these technical parameters directly translates into tangible operational benefits. For instance, the consistent arc stability provided by optimal deoxidizer levels in sg2 welding wire reduces burn-through and improves penetration control, especially crucial for automated welding systems where precision is paramount. Reduced spatter means less material waste and significantly less time spent on post-weld cleaning, thereby increasing overall throughput and reducing labor costs. The high ductility and impact toughness ensure that welded joints can withstand dynamic loading and harsh environmental conditions, critical for applications in heavy machinery, railway components, and offshore structures. Furthermore, the robust copper coating protects the wire during storage and feeding, extending its shelf life and preventing issues related to rust or corrosion that could otherwise contaminate the weld pool. The adaptability to both CO2 and mixed shielding gases allows manufacturers to fine-tune their welding process for specific needs, balancing penetration, bead appearance, and deposition rates. This detailed understanding of the technical specifications empowers engineers to make informed decisions that optimize their welding processes for maximum efficiency, quality, and cost-effectiveness, proving that the choice of welding wire is a strategic one, not merely a commodity purchase.

Diverse Application Scenarios and Industry Impact of SG2 Welding Wire

The robust mechanical properties and superior welding characteristics of sg2 welding wire make it an indispensable consumable across a vast array of industrial sectors, serving as the backbone for critical structural integrity and high-performance fabrication. Its versatility in handling various base metal conditions, particularly those with moderate mill scale or rust, significantly broadens its applicability compared to less deoxidized wires. In the automotive industry, SG2 is extensively used in the fabrication of chassis components, suspension systems, and body structures, where high strength, excellent fatigue resistance, and consistent weld quality are non-negotiable for passenger safety and vehicle longevity. The ability to achieve high deposition rates with minimal spatter also contributes to the efficiency of automated robotic welding lines, which are prevalent in modern automotive manufacturing. Similarly, the shipbuilding industry relies heavily on SG2 for constructing hulls, decks, and superstructures. The sheer volume of welding involved, combined with the need for exceptional strength and resistance to harsh marine environments, makes SG2 an ideal choice. Its robust properties ensure that vessels can withstand immense stresses and corrosive conditions over decades of service, reducing maintenance costs and enhancing operational reliability.

In the realm of heavy machinery and construction, sg2 welding wire plays a pivotal role in fabricating earthmoving equipment, cranes, structural steel beams for high-rise buildings, and bridge components. These applications demand welds that can endure extreme static and dynamic loads, often in challenging outdoor conditions. SG2's high tensile strength and superior impact toughness ensure that these massive structures and machines retain their structural integrity, minimizing the risk of catastrophic failures and extending their operational lifespan. For the petrochemical industry, where safety and containment are paramount, SG2 is crucial for welding pipes, pressure vessels, storage tanks, and various processing equipment. The ability to produce sound, defect-free welds with excellent penetration is critical for containing hazardous materials and withstanding high pressures and temperatures, preventing leaks and ensuring regulatory compliance. The energy efficiency aspect of SG2 welding, derived from its consistent arc stability and reduced need for re-work, directly translates to lower operational costs in these energy-intensive sectors, contributing to more sustainable practices.

Fig 3: SG2 welding wire being utilized in the fabrication of heavy industrial equipment, demonstrating its critical role in robust structural assemblies.

Furthermore, the utility of sg2 welding wire extends to general fabrication and repair shops, where its versatility shines in handling diverse tasks, from manufacturing custom components to repairing industrial equipment. Its consistent performance across various welding positions and with different shielding gases makes it a go-to choice for job shops seeking a reliable, all-purpose wire. The railway industry employs SG2 for fabricating rolling stock components, tracks, and structural elements of railway infrastructure, demanding high fatigue strength and resistance to vibrations. In water supply and drainage systems, SG2 is used for joining large-diameter pipes and fittings, where corrosion resistance (in conjunction with appropriate coatings or post-weld treatments) and leak-free integrity are essential for long-term municipal and industrial applications. The inherent properties of SG2, particularly its deoxidizing capabilities and robust mechanical strength, offer significant advantages in ensuring the longevity and integrity of these critical infrastructure projects. While a soldering copper wire would be used for joining copper pipes in residential plumbing for water supply, it's the strength and fusion of SG2 that makes it suitable for high-pressure, large-scale industrial water and drainage infrastructure, particularly when dealing with steel components. The anti-corrosion aspect isn't intrinsic to the SG2 wire itself, but its clean, sound welds provide an excellent base for subsequent anti-corrosion coatings, ensuring long-term protection in corrosive environments like those found in wastewater treatment facilities or offshore platforms. This synergy between inherent wire properties and external protection strategies maximizes the operational lifespan and reliability of welded structures.

The growing trend towards automation and robotics in manufacturing further amplifies the demand for high-quality sg2 welding wire. Robotic welding cells require consistent wire feedability, stable arc characteristics, and minimal spatter to maintain continuous operation and achieve precise, repeatable welds without human intervention. SG2's uniform diameter, excellent cast and helix, and superior copper coating contribute directly to its exceptional feedability, making it highly compatible with advanced automated systems. This leads to reduced downtime, higher throughput, and ultimately, a more competitive manufacturing process. Moreover, the enhanced mechanical properties of SG2 contribute to improved product performance and reliability, reducing warranty claims and enhancing brand reputation. Its ability to create strong, ductile welds that can withstand significant stress and impact is vital for components that are subjected to demanding operational cycles. The cumulative impact of these benefits—efficiency gains, enhanced product quality, and extended service life—underscores why SG2 is not just a welding consumable but a strategic enabler for industries aiming for operational excellence and long-term sustainability. The global move towards more robust and durable infrastructure projects, coupled with the increasing complexity of manufactured goods, ensures that the demand for materials like SG2, which offer both performance and reliability, will continue to grow significantly in the foreseeable future.

Manufacturer Comparison, Custom Solutions, and Strategic Partnerships

Choosing the right manufacturer for sg2 welding wire is a strategic decision that extends far beyond merely comparing price per kilogram. For B2B buyers, it involves a comprehensive evaluation of a manufacturer's commitment to quality, technological advancement, customer support, and the ability to provide tailored solutions. While many suppliers offer ER70S-6 wire, the subtle differences in their manufacturing processes, raw material sourcing, and quality control protocols can significantly impact the consistency and performance of the wire in real-world applications. A reputable manufacturer differentiates itself through rigorous adherence to international standards like ISO 9001, AWS, and CE, along with transparent reporting of test data and certifications. They invest heavily in R&D to continuously improve wire properties, such as arc stability, spatter reduction, and mechanical strength, often collaborating with leading academic institutions and industry experts. Furthermore, a strong track record of serving diverse industries, evidenced by a long service history and partnerships with prominent enterprises, speaks volumes about their reliability and expertise. Unlike generic suppliers, industry-leading manufacturers of sg2 welding wire emphasize total cost of ownership, recognizing that a slightly higher upfront cost for premium wire is often offset by substantial savings in reduced rework, higher productivity, and extended component lifespan.

Our product, the SG2 SG3 soldering Welding Wire er70s-6, represents the pinnacle of this commitment to excellence. We understand that standard products, while broadly applicable, may not always perfectly align with highly specialized welding requirements. This is where our expertise in custom solutions becomes invaluable. For large-scale projects or unique applications, we offer the flexibility to tailor the welding wire to precise client specifications. This can include adjustments to the chemical composition to fine-tune mechanical properties like tensile strength or impact toughness for specific base metals or challenging environmental conditions. We can also provide custom wire diameters beyond the standard range, or specific spool sizes and packaging configurations to seamlessly integrate with automated welding systems or particular logistical needs. Our technical team works closely with clients, often involving on-site consultations and joint R&D, to develop wire solutions that optimize their specific welding processes, reduce waste, and enhance overall productivity. This collaborative approach ensures that our sg2 welding wire not only meets but often exceeds the demanding performance expectations of our B2B partners. This level of customization and support sets us apart from mere distributors or generic manufacturers who offer a limited range of off-the-shelf products.

Fig 4: Custom packaging and spooling solutions for SG2 welding wire, designed to meet specific client requirements and optimize logistic efficiency.

Strategic partnerships are another cornerstone of our approach. We don't just supply wire; we forge long-term relationships built on trust, transparency, and mutual success. This involves proactive technical support, including troubleshooting, process optimization recommendations, and training for client welding teams. Our service extends beyond the initial purchase, with a commitment to ongoing consultation and problem-solving. This dedication to customer success is reflected in our robust after-sales service, comprehensive warranty programs, and efficient delivery cycles tailored to client production schedules. When evaluating manufacturers, it's essential to look for those who demonstrate a deep understanding of your industry's unique challenges and opportunities. For instance, in an industry heavily reliant on structural integrity such as bridge construction, a manufacturer's ability to provide detailed metallurgical reports and consistent batch quality for sg2 welding wire is far more valuable than a marginal price difference. Similarly, for high-volume automated lines in the automotive sector, consistent wire feedability and minimal spatter directly impact throughput and operational costs, making a premium wire a more cost-effective choice in the long run. By choosing a manufacturer like us, who prioritizes quality, innovation, and customer-centric solutions, businesses can ensure they are not just acquiring a product, but gaining a reliable partner capable of enhancing their overall welding efficiency and product quality. This collaborative paradigm, extending to bespoke product formulations and just-in-time delivery models, positions our clients for sustained competitive advantage in a dynamic global market.

Real-World Impact: Application Case Studies and Trust-Building Metrics

The theoretical advantages of sg2 welding wire translate into significant tangible benefits in real-world industrial applications. Our commitment to delivering high-performance products is best illustrated through successful case studies that highlight quantifiable improvements in efficiency, quality, and cost-effectiveness for our clients. For instance, a leading manufacturer in the heavy equipment sector faced persistent issues with high spatter rates and inconsistent weld quality when fabricating large structural components for excavators, leading to extensive post-weld grinding and increased material waste. After transitioning to our premium sg2 welding wire, they reported a remarkable 40% reduction in spatter, which translated to a 25% decrease in post-weld cleaning time and a 15% improvement in overall production throughput. The improved arc stability also reduced electrode consumption and extended liner life, contributing to further cost savings. This case demonstrates how a superior consumable directly impacts operational efficiency and bottom-line profitability, turning a recurring headache into a streamlined process.

Another compelling example comes from a prominent shipbuilding yard engaged in constructing large cargo vessels. They encountered challenges with achieving consistent penetration and mechanical properties in multi-pass welds on thick steel plates, impacting structural integrity and compliance with stringent maritime regulations. By implementing our sg2 welding wire, specifically designed for robust penetration and excellent deoxidizing capabilities, they observed a significant improvement in weld soundness, evidenced by a 98% reduction in porosity and inclusion defects during ultrasonic testing. The consistent mechanical properties of the weld metal, confirmed through extensive laboratory testing and certification, ensured that all critical structural joints met the highest classification society standards, such as Lloyd's Register and DNV GL. This enhanced quality not only boosted their reputation but also reduced the risk of costly rework and project delays, reinforcing the value of investing in high-quality welding consumables. This showcases our authoritative stance in the industry, with products rigorously tested to meet global benchmarks.

Fig 5: A close-up view of a high-quality weld joint, demonstrating the smooth bead appearance and minimal spatter achieved using SG2 welding wire.

To further build trust and demonstrate our unwavering commitment to quality and customer satisfaction, we adhere to the highest standards of transparency and support. Our FAQ module addresses common inquiries regarding product selection, technical specifications, storage, and troubleshooting, providing immediate access to critical information. For instance, common questions like "What is the difference between SG2 and sg3 welding wire?" or "What shielding gas should I use for optimal results with ER70S-6?" are thoroughly answered, leveraging our expertise to guide users towards best practices. We maintain highly efficient delivery cycles, typically fulfilling standard orders within 3-5 business days for domestic clients and 7-14 business days for international shipments, depending on the destination and order volume. For large or custom orders, lead times are clearly communicated and agreed upon in advance, ensuring predictable supply chain management for our clients. Every batch of our SG2 welding wire undergoes rigorous internal and third-party testing, with comprehensive test certificates available upon request, validating its compliance with AWS, ISO, and CE standards.

Our warranty commitment stands as a testament to the confidence we have in our product's quality and performance. We offer a comprehensive warranty against manufacturing defects and non-compliance with published specifications for a period of [e.g., 12 months] from the date of purchase. This commitment provides our clients with peace of mind and minimizes their operational risks. Beyond the warranty, our dedicated customer support team is available [e.g., 24/7 or during business hours] to provide technical assistance, answer product-related queries, and facilitate order processing. This holistic approach, combining superior product quality with transparent processes and robust support infrastructure, underpins our trustworthiness as a long-term partner for B2B enterprises. The consistent positive feedback from our diverse client base, spanning industries from infrastructure development to precision engineering, further validates our reputation as a reliable and expert supplier of sg2 welding wire. We empower businesses not just with a product, but with a comprehensive solution that includes unparalleled technical guidance and a steadfast commitment to their success, ensuring that every weld contributes positively to their operational excellence and market leadership. This dedication to total customer experience, from initial inquiry through post-purchase support, is what truly defines our value proposition in the competitive welding consumables market.

Frequently Asked Questions (FAQ) about SG2 Welding Wire

Q1: What is the primary difference between SG2 (ER70S-6) and SG3 (ER70S-3) welding wires?

A1: The primary difference lies in their deoxidizer content. SG2 welding wire (ER70S-6) contains higher levels of Manganese (Mn) and Silicon (Si), making it more effective at deoxidizing the weld pool and tolerating contaminants like mill scale, rust, and dirt on the base metal. SG3 welding wire (ER70S-3) has lower deoxidizer levels and is generally recommended for welding on cleaner, bright, or deoxidized base metals where minimal contamination is present. SG2 offers superior arc stability and less spatter, especially on less prepared surfaces.

Q2: What shielding gases are recommended for SG2 (ER70S-6) welding wire?

A2: SG2 welding wire (ER70S-6) is highly versatile and can be used with various shielding gases. For general purpose welding, a mixture of 75-90% Argon (Ar) and the remainder Carbon Dioxide (CO2) (e.g., 75% Ar / 25% CO2) is commonly recommended as it provides a stable arc, low spatter, and good bead appearance. For deeper penetration and higher deposition rates, 100% CO2 can be used, although it typically results in more spatter and a slightly rougher bead.

Q3: Can SG2 welding wire be used for automated welding processes?

A3: Absolutely. SG2 welding wire (ER70S-6) is exceptionally well-suited for automated and robotic welding applications due to its consistent wire diameter, excellent cast and helix, and superior copper coating. These properties ensure smooth and reliable wire feeding, minimize tangles and bird-nesting, and contribute to stable arc performance, all of which are critical for high-volume, precision automated welding.

Q4: How does the copper coating on SG2 wire benefit welding performance?

A4: The thin, uniform copper coating on SG2 welding wire serves multiple crucial purposes. It enhances electrical conductivity, ensuring consistent current transfer and arc stability. It acts as a lubricant, facilitating smooth wire feeding through the welding gun liner and contact tip, which reduces friction and prevents burn-back. Additionally, it provides a degree of corrosion resistance, protecting the wire during storage and handling from rust and oxidation that could otherwise affect weld quality.

Q5: What are the typical industries where SG2 welding wire is predominantly used?

A5: SG2 welding wire (ER70S-6) is widely utilized across various heavy fabrication industries due to its robust mechanical properties and excellent welding characteristics. Key sectors include automotive (chassis, structural components), shipbuilding (hulls, superstructures), heavy machinery (excavators, cranes), construction (structural steel, bridges), petrochemical (pipelines, pressure vessels), and general fabrication and repair shops. Its versatility and ability to handle moderately contaminated surfaces make it a preferred choice for demanding applications.

Industry References & Further Reading

- American Welding Society (AWS) A5.18/A5.18M: Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding - Essential industry standard defining SG2 (ER70S-6) and related classifications.

- The Welding Institute (TWI): MIG/MAG Welding Process Explained - A comprehensive resource on GMAW principles, relevant to SG2 applications.

- JFE Steel Technical Report: Development of High Efficiency Welding Materials - Insights into advancements in welding wire technology and their impact on productivity.

- ESAB: How to Select the Right MIG Wire - Practical guide for choosing appropriate wires, including SG2 considerations.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025