china er70s-g welding wire factory

The Emergence of China ER70S-G Welding Wire Factories A Key Player in Global Manufacturing

In today’s fast-paced manufacturing environment, the demand for high-quality welding materials has increased significantly. One of the leading products in this domain is the ER70S-G welding wire, known for its excellent performance in various welding applications. China, as a global manufacturing powerhouse, has established a vast network of factories dedicated to producing ER70S-G welding wire, catering to both domestic and international markets.

What is ER70S-G Welding Wire?

ER70S-G is a mild steel welding wire that is used primarily in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW). The ER stands for electrode and rod, while 70 signifies the tensile strength of the wire, which is a minimum of 70,000 psi. The S means it is suitable for a variety of applications, and the G indicates the wire is appropriate for general-purpose welding. This welding wire is known for its excellent weldability, good impact toughness, and can be used to weld in various positions, making it a favorite among industry professionals.

The Role of Chinese Factories

Chinese ER70S-G welding wire factories have rapidly gained recognition for their ability to produce high-quality welding materials at competitive prices. With advanced manufacturing technologies and stringent quality control protocols, these factories maintain a consistent output of welding wire that meets international standards. The combination of state-of-the-art machinery and skilled labor allows these factories to meet the diverse needs of global markets.

Advantages of Chinese ER70S-G Welding Wire

1. Cost-Effectiveness One of the primary advantages of sourcing ER70S-G welding wire from China is its cost-efficiency. The country’s extensive manufacturing infrastructure enables factories to produce in bulk, which reduces overall production costs. This translates to lower prices for buyers, making it an attractive option for businesses looking to minimize expenses without compromising quality.

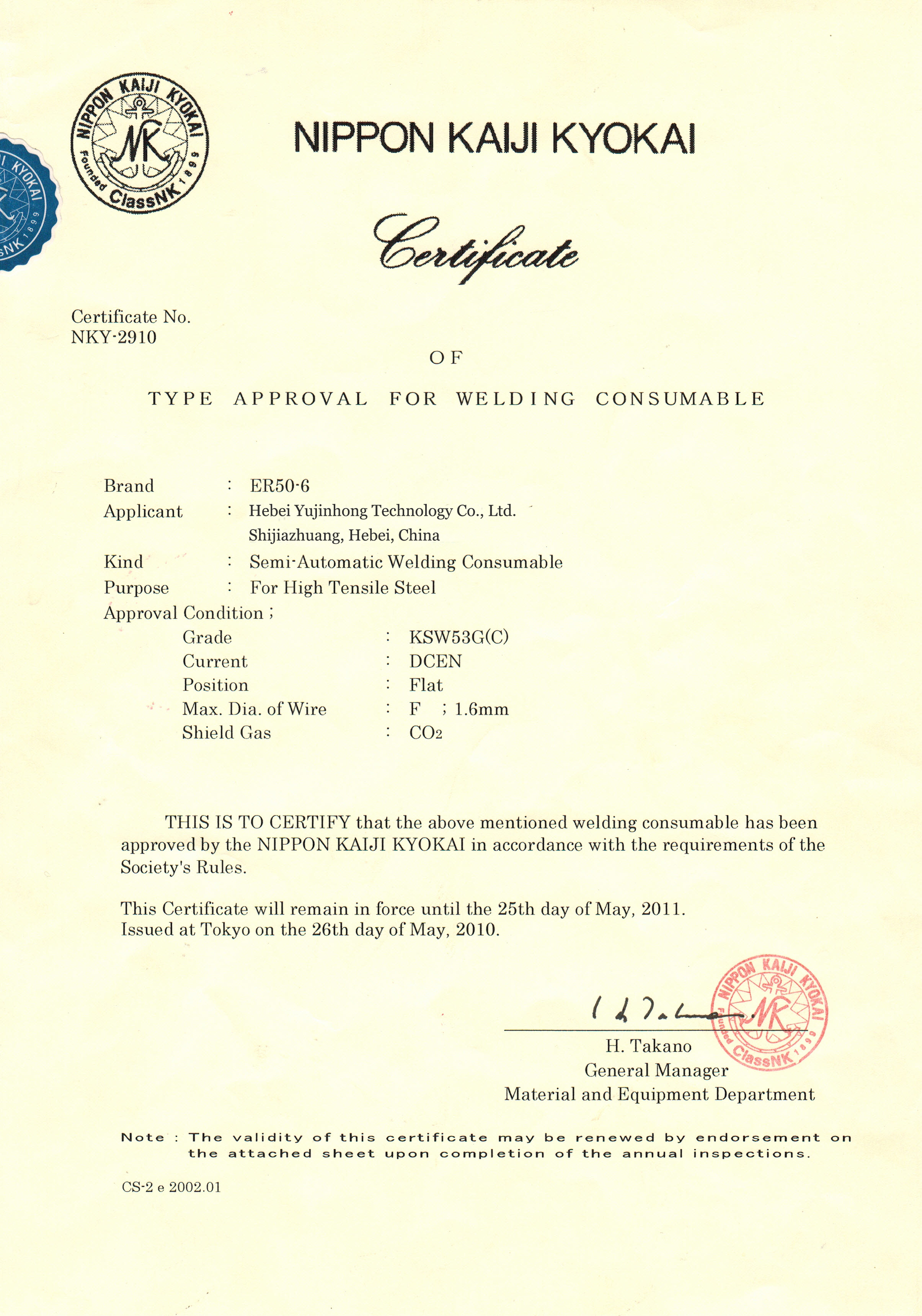

2. High Quality and Compliance Despite the lower costs, Chinese manufacturers often meet rigorous quality standards, such as ISO certifications. Many factories employ advanced technology and skilled workers, ensuring that their products exhibit consistent quality and performance. This capability is crucial, especially for industries such as construction, automotive, and shipbuilding, where the integrity of welds is paramount.

china er70s-g welding wire factory

3. Diverse Product Range Chinese factories offer a vast array of welding wires, including variations in diameter, coating, and packaging. This diversity enables customers to find the specific product that meets their unique requirements, whether it’s for general fabrication or specialized applications.

4. Reliable Supply Chain China’s extensive logistics network ensures that welding wire can be delivered promptly and efficiently worldwide. This reliable supply chain allows businesses to maintain their production schedules without delays.

Impact on Global Markets

The rise of China’s ER70S-G welding wire factories is reshaping the global welding industry. Countries that previously dominated the market are now adapting to compete with the high-quality, cost-effective products coming out of China. This shift has resulted in increased competition, which ultimately benefits consumers through better pricing and innovation.

Challenges and Sustainability

While Chinese factories are thriving, they also face challenges. Environmental concerns regarding emissions from manufacturing processes have led to increased scrutiny. Many factories are now implementing greener practices to minimize their ecological footprint and adhere to evolving regulations. Sustainable production methods not only appeal to environmentally-conscious consumers but also align with global efforts to combat climate change.

Conclusion

The proliferation of ER70S-G welding wire factories in China signifies a critical evolution in the global manufacturing landscape. With their ability to produce high-quality welding materials at competitive prices, these factories are not only meeting but exceeding the expectations of customers around the world. As they continue to innovate and adapt to emerging challenges, Chinese manufacturers will play an increasingly significant role in shaping the future of welding and fabrication industries.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025