China MIG Welding Wire Manufacturer for Quality and Reliability in Welding Solutions

The Rise of China’s MIG Wire Welding Manufacturers

In recent years, China has established itself as a global leader in manufacturing, and this includes the production of welding supplies, particularly Metal Inert Gas (MIG) welding wire. As the demand for welding applications continues to rise across various industries, China’s MIG wire welding manufacturers have positioned themselves to meet both domestic and international needs, driving innovation and quality in the welding sector.

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a widely used welding process that utilizes a continuous solid wire electrode and a shielding gas to protect the weld pool from contamination. This technique is favored for its speed and versatility, making it suitable for a range of applications, from automotive manufacturing to construction and repair work. The demand for high-quality MIG wire has surged, leading to the growth of specialist manufacturers in China.

Abundant Resources and Competitive Pricing

China’s ascent as a manufacturing powerhouse is partly due to its abundant resources and skilled workforce. The country is rich in raw materials essential for producing high-quality welding wires, such as steel and alloys. Furthermore, the scale of production allows Chinese manufacturers to achieve economies of scale, significantly reducing costs. This competitive pricing makes Chinese MIG welding wires an attractive option for companies around the globe, allowing them to maintain quality while managing their budgets effectively.

Innovation and Technology

Chinese manufacturers are not just focusing on the quantity of production but are also emphasizing innovation and technological advancement. Modern MIG wires are engineered to provide superior performance, including improved feedability, arc stability, and lower spatter levels. Many manufacturers invest in research and development to enhance their products, ensuring that they meet the stringent demands of various industries.

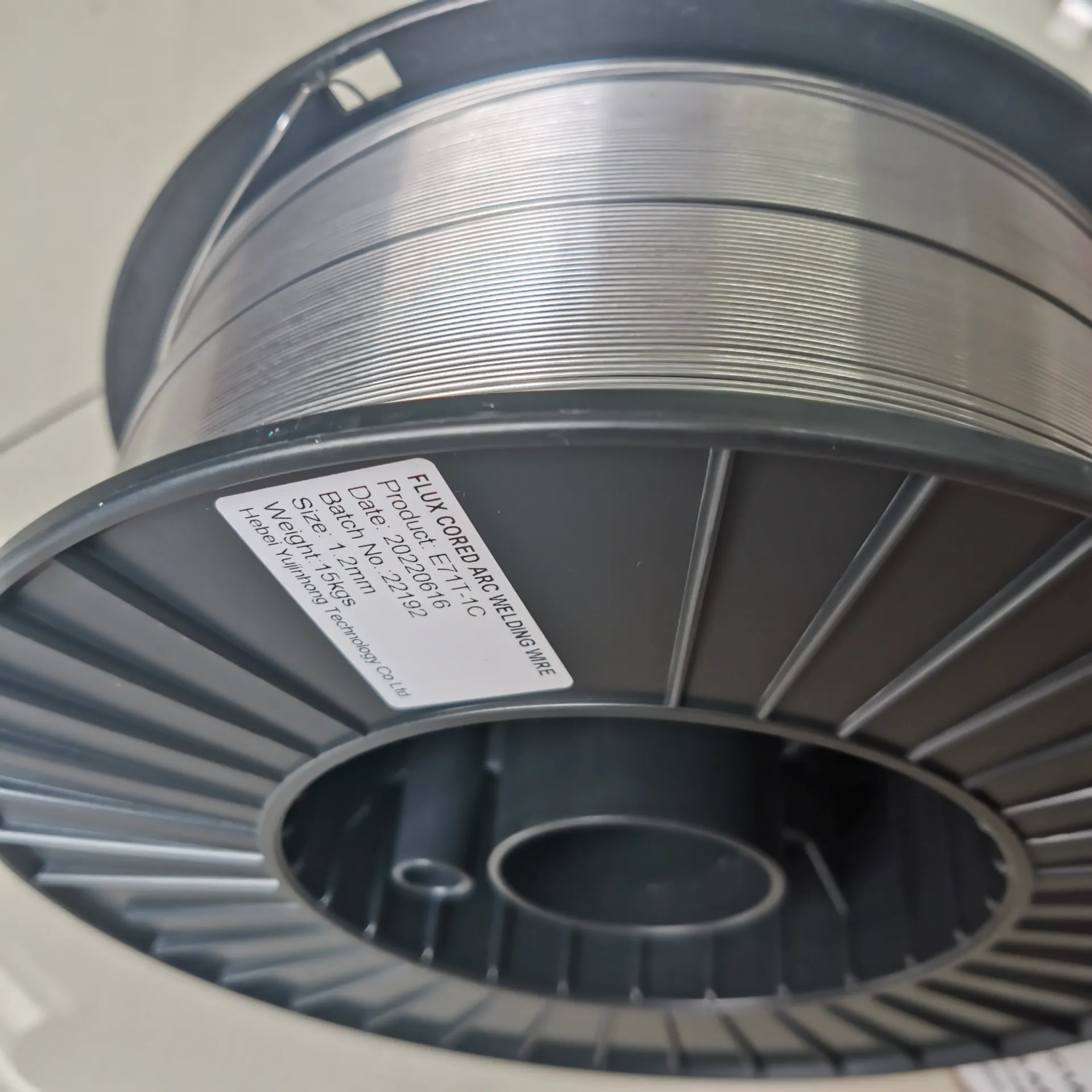

china mig wire welding manufacturer

For instance, some companies have adopted advanced manufacturing techniques such as automated production lines and quality control systems, ensuring consistency and reliability in their welding wires. By utilizing state-of-the-art technology, these manufacturers can produce MIG wires that meet international standards, thereby enhancing their competitiveness in the global market.

Export Markets and Global Reach

China's MIG wire welding manufacturers have successfully penetrated international markets, exporting their products to countries around the world. This global reach has been facilitated by various trade agreements and China's emphasis on infrastructure development. Many manufacturers actively participate in international trade shows and exhibitions to showcase their offerings and build relationships with overseas buyers.

Moreover, as the world increasingly focuses on sustainable practices, Chinese manufacturers are adapting their products to meet environmental regulations and standards. This includes the development of eco-friendly wires that produce minimal emissions during the welding process, catering to companies looking to diminish their environmental impact.

Challenges Ahead

Despite the evident growth and success, Chinese MIG wire welding manufacturers face several challenges. Intense competition from other manufacturing countries, particularly in Southeast Asia and Europe, poses a threat to market share. Additionally, fluctuations in raw material prices can impact production costs. Furthermore, manufacturers must continuously adapt to the evolving demands of industries, which require consistent innovation and product development.

Conclusion

The rise of China’s MIG wire welding manufacturers represents a remarkable journey of growth and transformation in the global manufacturing landscape. By leveraging abundant resources, focusing on innovation, and expanding their reach, these manufacturers have positioned themselves as key players in the welding industry. As demand for high-quality welding solutions continues to grow, the role of Chinese manufacturers will undoubtedly expand, shaping the future of technology in welding processes. Keeping an eye on this industry is essential for stakeholders globally, as the landscape is set to evolve even further in the years to come.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025