Factories Manufacturing Electrode Welding Sticks for Efficient and Reliable Welding Solutions

The Evolution and Significance of Electrode Welding Sticks Factories

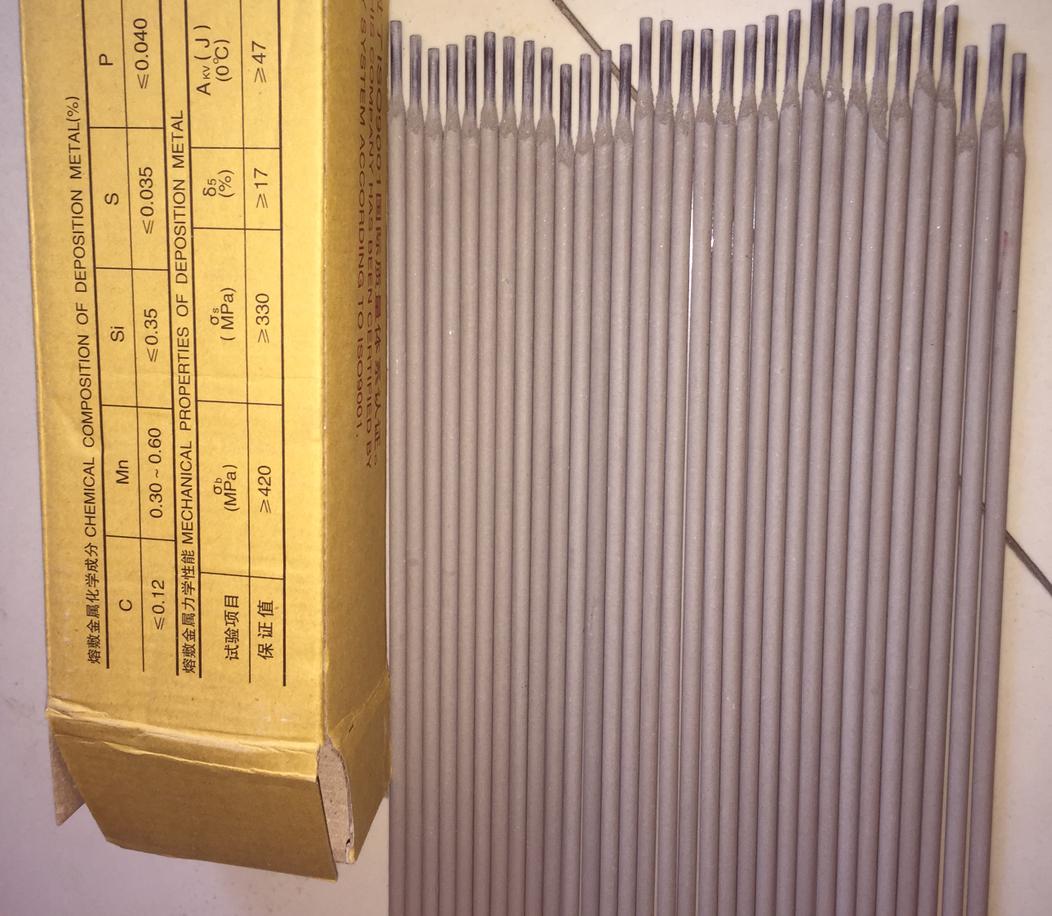

In the realm of metal joining technologies, electrode welding sticks have played an invaluable role in various industrial applications. These consumable sticks, often referred to as welding electrodes, are essential components in arc welding processes, such as Shielded Metal Arc Welding (SMAW) and others. As industries expand and require more efficient and reliable welding solutions, the significance of electrode welding sticks factories has become increasingly pronounced.

The Basics of Electrode Welding

Welding, at its core, is a process that involves joining materials, usually metals or thermoplastic, through the application of heat, pressure, or both. Electrode welding employs a filler material in the form of a stick or rod that melts and joins the base metals. The quality and performance of these welding electrodes directly influence the strength and integrity of the weld joint. Therefore, the manufacturing of welding sticks is a critical aspect of the welding industry.

The Function of Electrode Welding Sticks

Electrode welding sticks are designed to create a stable arc, transfer heat effectively, and provide filler material that solidifies to form a strong bond. They come in various compositions and coatings, each tailored for specific applications, metal types, and environmental conditions. For instance, some electrodes are formulated for welding carbon steel, while others are optimized for stainless steel or cast iron. The coatings on the welding sticks also serve vital functions, such as shielding the molten weld pool from contaminants, stabilizing the arc, and enhancing the overall weld quality.

The Manufacturing Process

The production of electrode welding sticks is a meticulous process that involves several stages. Raw materials, including metal powders and flux materials, are carefully selected based on the desired properties of the final product. These materials undergo a compounding process, where they are mixed and shaped into rods. Following this, the rods are coated with a layer of flux, and the entire assembly is cured to enhance durability.

electrode welding sticks factories

Factories dedicated to manufacturing welding electrodes employ advanced technologies and quality control measures to ensure consistency and reliability. Automating certain stages of the process enhances efficiency, allowing for large-scale production without compromising quality. Moreover, modern electrode welding sticks factories are increasingly focusing on sustainability, recycling materials, and reducing waste – a crucial consideration as industries around the globe move towards greener practices.

Market Demand and Trends

The demand for welding electrodes is primarily driven by growth across various sectors, including construction, automotive, shipbuilding, and manufacturing. As the economies of developing nations expand, the need for infrastructure and industrialization continues to grow, leading to a heightened demand for welding solutions. Furthermore, innovations in welding technologies, such as the use of robotics and automation, are changing the landscape of manufacturing and construction, further propelling the market for electrode welding sticks.

As industries evolve, there are trends towards specialized welding electrodes designed for specific applications, such as high-temperature or wear-resistant materials. Additionally, the demand for repair and maintenance services is fostering the development of versatile welding products that cater to different conditions and environments.

Challenges Faced by Factories

Despite the growing demand, factories producing electrode welding sticks encounter several challenges. Fluctuating raw material prices, competitive markets, and stringent regulatory requirements could impact production costs and timelines. Additionally, maintaining a skilled workforce is essential for ensuring quality and safety standards in manufacturing processes.

Conclusion

The significance of electrode welding sticks factories in the modern industrial landscape cannot be overstated. As the backbone of the welding industry, these factories not only supply essential materials for metal joining but also contribute to technological advances and sustainability efforts within their operations. As the world progresses towards more complex and demanding applications, the evolution of electrode welding technologies and the factories producing them will undoubtedly play a critical role in shaping the future of industrial welding. As industries continue to innovate, the need for high-quality welding solutions will remain paramount, ensuring that electrode welding sticks will remain in demand for years to come.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025