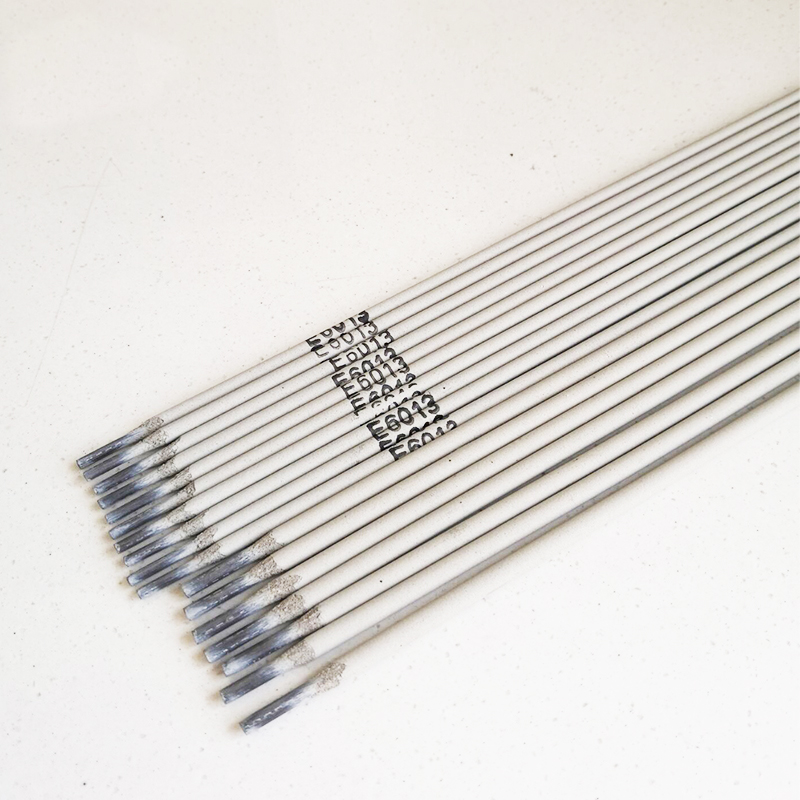

Aluminum Welding Rods for High-Quality and Reliable Stick Welding Solutions

Understanding Aluminum Welding Rods A Guide for Manufacturers

Aluminum welding rods are essential materials in the manufacturing sector, particularly for processes involving the joining of aluminum components. These rods have become increasingly popular due to the lightweight and strong nature of aluminum, making it a preferred choice in various industries, from aerospace to automotive. This article delves into the intricacies of aluminum stick welding rods, particularly focusing on manufacturers, their applications, and key considerations.

The Importance of Aluminum Welding Rods

Aluminum welding rods serve multiple functions in the welding process, primarily acting as filler materials that facilitate the joining of aluminum parts. Their usage ensures structural integrity and enhances the overall durability of welded products. The right choice of welding rod is critical, as it influences the quality of the weld, the appearance of the finished product, and its performance under various conditions.

Types of Aluminum Welding Rods

There are several types of aluminum welding rods available on the market, each suited for different welding techniques and applications. The most common types include

1. ER4047 This is a popular choice for welding aluminum and its alloys. Known for its excellent corrosion resistance and good fluidity, it is often used in automotive applications.

2. ER4045 This alloy is especially useful for welding aluminum to aluminum and aluminum to other metals. It produces a smooth and clean finish, making it ideal for aesthetic applications.

3. ER5356 This rod is known for its high strength and resistance to stress corrosion cracking. It’s commonly used in marine applications due to its ability to withstand seawater.

4. ER4040 Often used for brazing, this rod is effective for welding aluminum to other non-ferrous metals.

Each type has unique properties that make it appropriate for specific applications, and manufacturers must carefully choose the right type based on the requirements of their projects.

Choosing a Manufacturer

When selecting an aluminum welding rod manufacturer, there are several key factors to consider

welding rod aluminum stick manufacturer

- Quality Standards Ensure the manufacturer adheres to industry standards and certifications

. Quality control processes should be in place to guarantee that the rods meet desired specifications.- Material Specifications Verify that the aluminum welding rods are made from high-quality materials that enhance their performance and durability.

- Customization Options A good manufacturer should offer customization options to meet unique welding needs, as different projects may require specific rod compositions or sizes.

- Support and Technical Expertise Manufacturers should provide technical support and guidance regarding the most suitable welding rods for specific applications.

- Reputation and Reviews Look for manufacturers with a proven track record. Customer reviews and case studies can provide insights into their reliability and product performance.

Applications of Aluminum Welding Rods

The versatility of aluminum welding rods allows them to be used in various sectors

- Aerospace The lightweight nature of aluminum is crucial in aircraft manufacturing, where reducing weight can lead to improved fuel efficiency.

- Automotive Aluminum welding rods are commonly used in car manufacturing, particularly for body panels and engine components, thereby enhancing performance and efficiency.

- Marine Due to their resistance to corrosion, aluminum welding rods are perfect for boat building and repairing applications.

- Construction Aluminum is increasingly used in construction for windows, door frames, and other structural components.

Conclusion

Aluminum stick welding rods play a pivotal role in ensuring the successful welding of aluminum components across various industries. Selecting the right manufacturer and type of welding rod can lead to significant improvements in the quality and durability of welded products. With the right knowledge and partnerships, manufacturers can achieve remarkable results, driving innovation and efficiency in their projects. Whether you are in aerospace, automotive, marine, or construction, understanding the significance of aluminum welding rods is essential for any successful welding endeavor.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025