Jan . 31, 2025 02:30

Back to list

3 32 7018 welding rod

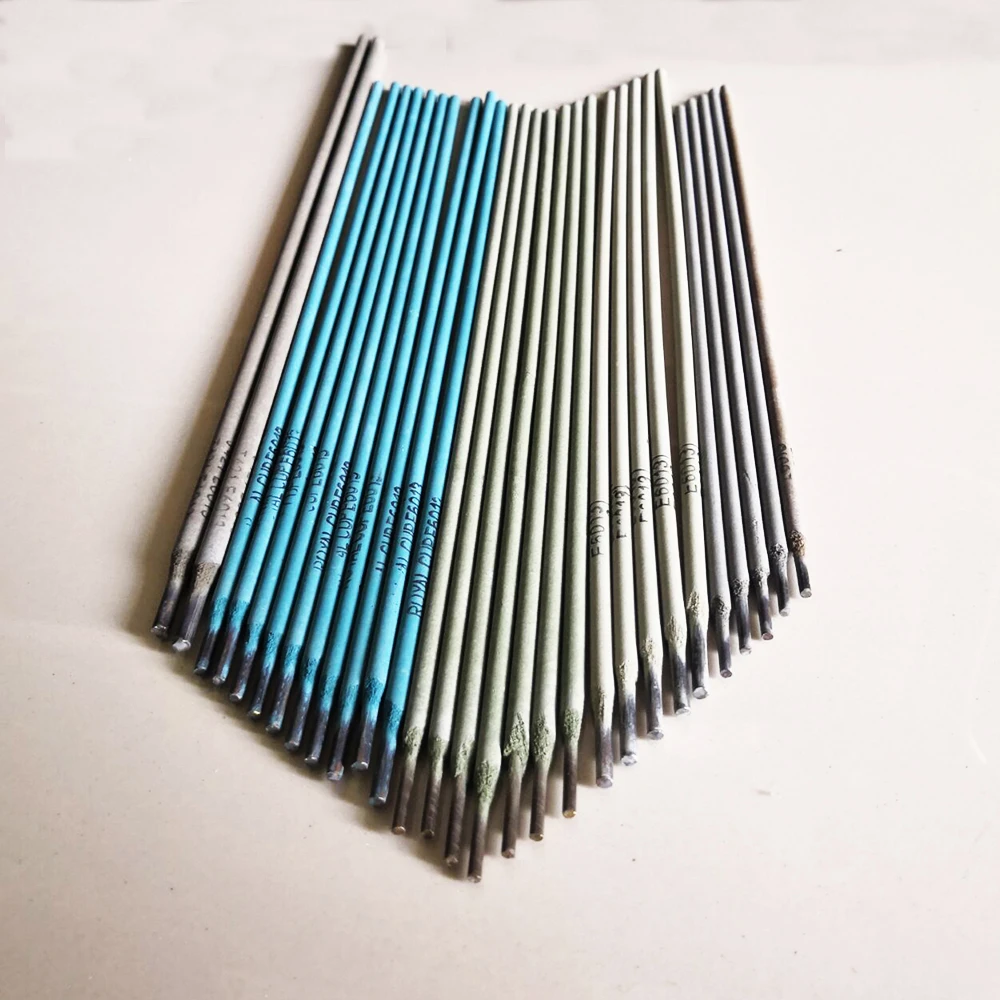

Navigating the dynamic world of welding requires dedication, expertise, and the right tools to achieve optimal results. The welding industry is built upon precision and safety, with an emphasis on using materials that not only meet quality standards but also enhance performance. The 3 32 7018 welding rod has emerged as a centerpiece for professional welders, setting benchmarks in various welding applications due to its unique characteristics and benefits.

From an expertise standpoint, utilizing the 7018 electrode demands familiarity with the proper maintenance of the rods. Maintaining these rods' low-hydrogen properties is essential; hence, they must be stored in conditions devoid of moisture, typically using a rod oven, until they are needed for use. This is crucial because moisture can compromise the integrity of the weld by introducing hydrogen, which can lead to undesirable porosity or hydrogen-induced cracking post-cooling. Authoritative voices in the welding industry consistently underscore the 7018 rod's reliability. Welding codes and standards, such as those prescribed by the American Welding Society (AWS), often specifically endorse the use of E7018 for structural welding, credited to its tensile strength of 70,000 psi and excellent impact resistance even at low temperatures. Its consistent performance in diverse conditions supports its widespread acceptance among professional welders and inspectors alike. Regarding trustworthiness, real-world testimonials and educational endorsements reinforce confidence in the 3 32 7018 welding rod's capabilities. User experiences frequently highlight its forgiving nature with regards to variations in operator skill level, making it an ideal electrode for both novice welders seeking to improve their craft, and seasoned professionals involved in critical welding operations. Manufacturers provide detailed specifications and guidelines that align with industry safety standards, further cementing the trust in this rod as a reliable partner in welding endeavors. In conclusion, the 3 32 7018 welding rod is not merely a choice in welding; it is a strategic resource that combines precision, versatility, and reliability. Its application spans a spectrum of welding tasks, reinforcing structures pivotal to safety and performance. Whether in the hands of an amateur or a veteran, this welding rod stands out as a testament to engineering excellence and dedication to quality in the field of welding.

From an expertise standpoint, utilizing the 7018 electrode demands familiarity with the proper maintenance of the rods. Maintaining these rods' low-hydrogen properties is essential; hence, they must be stored in conditions devoid of moisture, typically using a rod oven, until they are needed for use. This is crucial because moisture can compromise the integrity of the weld by introducing hydrogen, which can lead to undesirable porosity or hydrogen-induced cracking post-cooling. Authoritative voices in the welding industry consistently underscore the 7018 rod's reliability. Welding codes and standards, such as those prescribed by the American Welding Society (AWS), often specifically endorse the use of E7018 for structural welding, credited to its tensile strength of 70,000 psi and excellent impact resistance even at low temperatures. Its consistent performance in diverse conditions supports its widespread acceptance among professional welders and inspectors alike. Regarding trustworthiness, real-world testimonials and educational endorsements reinforce confidence in the 3 32 7018 welding rod's capabilities. User experiences frequently highlight its forgiving nature with regards to variations in operator skill level, making it an ideal electrode for both novice welders seeking to improve their craft, and seasoned professionals involved in critical welding operations. Manufacturers provide detailed specifications and guidelines that align with industry safety standards, further cementing the trust in this rod as a reliable partner in welding endeavors. In conclusion, the 3 32 7018 welding rod is not merely a choice in welding; it is a strategic resource that combines precision, versatility, and reliability. Its application spans a spectrum of welding tasks, reinforcing structures pivotal to safety and performance. Whether in the hands of an amateur or a veteran, this welding rod stands out as a testament to engineering excellence and dedication to quality in the field of welding.

Previous:

Next:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025