China's 2016 Welding Rod Manufacturing Industry and Factory Insights

A Comprehensive Overview of China's 2016 Welding Rod Factories

In 2016, China emerged as a significant player in the manufacturing of welding rods, underlining its status as a global leader in the welding industry. The nation’s extensive network of industrial facilities and its robust supply chain have allowed it to produce high-quality welding rods at competitive prices. This article explores the factors that contributed to the growth of the welding rod manufacturing sector in China during this period, highlights some prominent factories, and examines the implications for the global market.

Growth Factors

Several factors contributed to the boom of welding rod factories in China in 2016. Firstly, the increasing demand for construction and infrastructure development spurred the need for efficient welding solutions. As China continued its rapid urbanization and industrialization, the construction of buildings, bridges, and roads created a substantial demand for welding materials. Consequently, manufacturers ramped up production to meet this growing need.

Secondly, technological advancements played a significant role in enhancing the efficiency and quality of welding rods produced. Factories invested in modernizing their machinery and adopting automated processes, which not only boosted production capacities but also improved product consistency. With the introduction of advanced metallurgy techniques, manufacturers were now able to produce welding rods that offered superior performance in terms of strength and durability.

Moreover, the Chinese government’s policies aimed at promoting the manufacturing sector provided a favorable environment for the growth of welding rod factories. Initiatives such as tax incentives, subsidies for modernization, and exports support encouraged many small and medium-sized enterprises (SMEs) to enter the welding rod market.

Prominent Factories

In 2016, numerous factories across China specialized in welding rod production, with some standing out for their scale and innovation. Companies like Zhejiang Shenzhou Welding Group and Hunan Yujin Special Steel Co., Ltd. emerged as leading players in the industry.

Zhejiang Shenzhou Welding Group, known for its wide range of products, specialized in producing various types of welding rods and consumables. The company leveraged its advanced technology and skilled workforce to cater not only to domestic demands but also to international markets, exporting a significant percentage of its production.

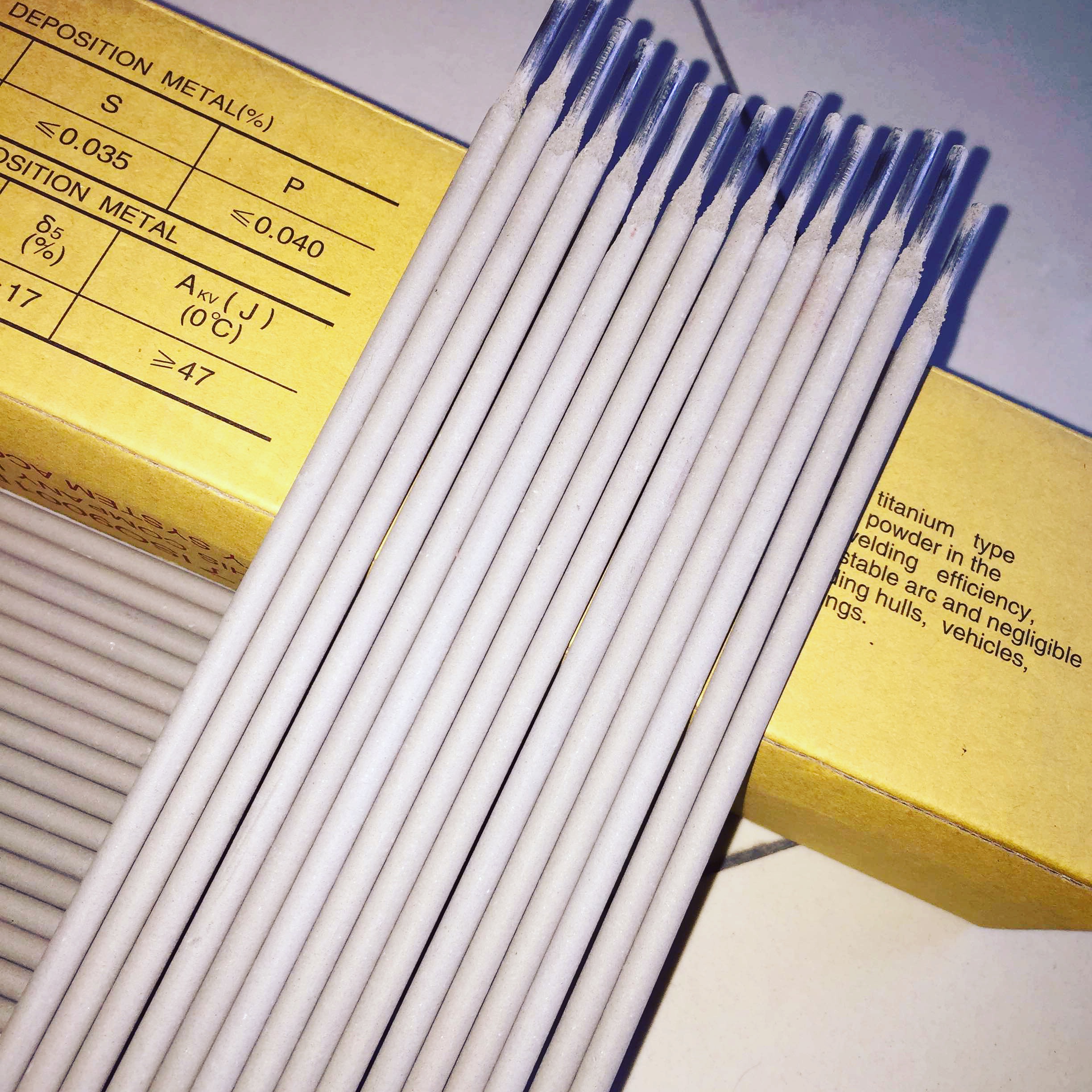

china 1 16 welding rod factories

Hunan Yujin Special Steel Co., Ltd., on the other hand, focused on producing high-performance welding rods designed for specific applications, including shipbuilding and heavy machinery. The company’s commitment to research and development helped it maintain a competitive edge in the market, ensuring that its products met the evolving needs of its clients.

Contribution to Global Market

The impact of China’s welding rod factories on the global market in 2016 was substantial. As the country ramped up its production capabilities, it began exporting significant quantities of welding rods to various regions, including North America, Europe, and Asia. This influx of Chinese-made welding rods resulted in increased competition in the global market, driving down prices and pushing other manufacturers to improve their products and services.

The affordability of Chinese welding rods also enabled smaller enterprises in foreign markets to engage in projects that may have otherwise been beyond their budgetary constraints. This democratization of access to quality welding materials fostered growth in various industries across the globe.

Challenges and Future Outlook

Despite the successes, the welding rod manufacturing sector in China faced challenges in 2016, including environmental concerns and trade disputes. The high energy consumption and emissions associated with manufacturing processes prompted scrutiny from both the government and environmental organizations. This necessitated a shift towards cleaner production techniques and compliance with stringent regulations.

Looking forward, the future of welding rod factories in China appears promising. Continued investments in technology, innovation, and sustainability will likely ensure that the sector remains competitive on the global stage. Furthermore, as industries evolve and new applications for welding rods emerge, Chinese manufacturers are well-positioned to adapt and thrive.

Conclusion

In summary, China’s welding rod factories in 2016 played a crucial role in shaping the global welding market. With their extensive production capabilities, strategic advancements, and responsiveness to market demands, these factories not only met domestic needs but also substantially influenced international supply chains. As the industry continues to evolve, China’s commitment to quality and innovation will be key determinants of its future success.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025