AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy Use

As one of the core consumables for modern metal fabrication, Arc welding electrodes AWS E7024 have become industry standards for joining carbon steel structures rapidly and efficiently. With surging demand in energy, infrastructure and heavy industries, this article delivers a comprehensive, technical, and data-backed perspective—covering parameters, leading vendors, custom solutions, and verified field applications.

Industry Trends for Arc welding electrodes AWS E7024 in 2024

- Global demand in arc welding electrodes is forecasted to reach over 1.7 million tons by 2024 (Grand View Research), with AWS E7024 leading growth due to infrastructure and shipbuilding investments.

- Technology upgrades: E7024 electrodes incorporate high-iron powder coatings and optimized flux for higher deposition rates, outperforming traditional E6013/E7018 in automated lines.

- Eco-mandates: Manufacturing trends focus on low-emission binders and sustainable mineral sourcing to comply with ISO 14001 environmental standards.

- Regional shifts: Asia-Pacific currently dominates supply (~43%, 2023), but North America shows strong standardization push with ANSI/AWS/ISO protocol adoption.

Technical Parameters: Arc welding electrodes AWS E7024 Data Table

| Parameter | Description/Value | Standard |

|---|---|---|

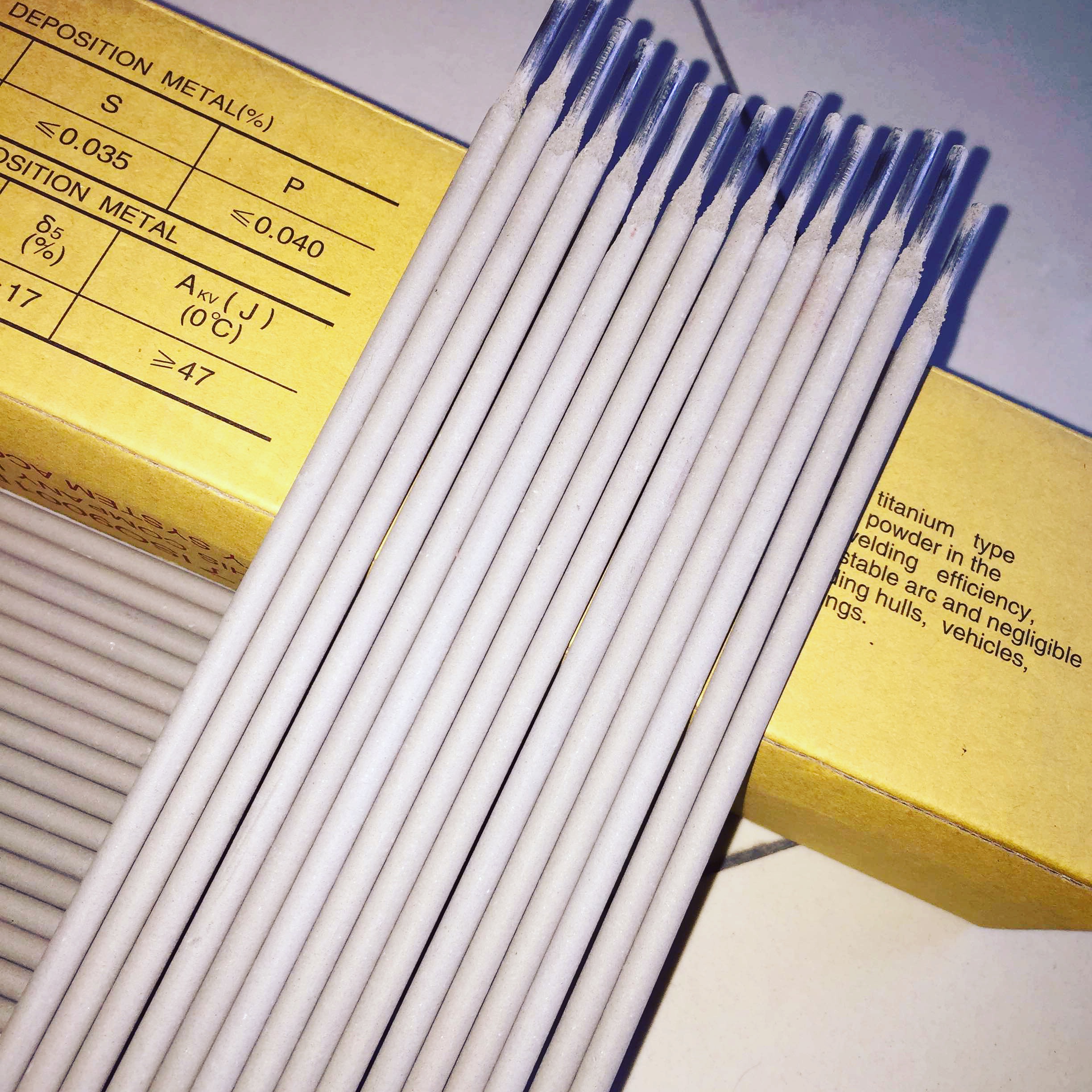

| Type | Iron powder, rutile coating | AWS A5.1/A5.1M:2020 |

| Diameter (mm) | 2.5、3.2、4.0、5.0 | ISO 2560-A |

| Length (mm) | 300–450 | Customizable |

| Tensile Strength (MPa) | >490 | AWS/ISO |

| Yield Strength (MPa) | >400 | AWS, GB/T 5117 |

| Elongation (%) | >20 | ISO 2560-A |

| Deposition Rate (kg/hr) | 8.5 – 13 | Test: ISO 17632 |

| Operating Current (A) | AC/DC: 80–300 | ANSI/AWS |

| Recommended Positions | Flat, horizontal fillet | AWS |

| Welding Polarity | AC or DC+ | |

| Approvals | ABS, Lloyd’s, ISO, CCS | Third-party |

| Coating Factor (%) | Up to 50% iron powder | ISO 2560-A |

Manufacturing Process Flow: Arc welding electrodes AWS E7024

- Steel: Certified low-carbon (Q195/235) for optimum ductility and weldability

- Coating: High iron powder content → raises deposition rate (> 13kg/h in 5mm rods)

- Machining: All rods CNC cut → strict length tolerance (±1.0mm)

- Testing: Follows ISO 9001, ISO 2560, AWS A5.1; each batch X-ray & mechanical specimen validation

- Packaging: Moisture-proof cartons, traceable batch QR code

Material & Technology Advantages of Arc welding electrodes AWS E7024

- Material: Low-carbon steel core, 98%+ purity, coated with rutile/iron powder; guarantees arc stability and minimal slag inclusions.

- Technology: Fully automated mixing and extrusion, ISO 9001:2015 managed, controlled for chemical uniformity; surface coating bonds micrometer-thin for reduced spatter loss.

- Corrosion Resistance: Rutile and iron powder layer protects weld zone with superior anti-porosity and easy slag removal — extends service life up to 20% compared to E6013 (field study by ICCW, 2022).

- Deposition Efficiency: Up to 190% efficiency in flat fillet application; benchmarks at 11.2 kg/hour in automated stations (5mm rod).

- Third-party Testing: Each lot validated under AWS, Lloyd’s Register, ABS or ISO welding test protocols.

Performance Benchmark: E7024 vs E6013 & E7018

- Steel construction (40%)

- Shipbuilding (32%)

- Boilers/petrochemical (18%)

- General fab (10%)

Global Manufacturers: Arc welding electrodes AWS E7024 Comparison Table

| Brand | Country | Certifications | Iron Powder (%) | Deposition Rate (kg/hr) | Warranty |

|---|---|---|---|---|---|

| STEELTOOLSCHINA | China | ISO 9001, Lloyd’s, CCS, ABS | 45–50% | 12–13 | 18 months |

| Lincoln Electric | USA | AWS, ABS, ISO | 46% | 12.5 | 12 months |

| Böhler Welding | Austria | ISO, DNV, Lloyd’s | 44% | 11.8 | 24 months |

| Hyundai Welding | South Korea | ISO, KR, LR | 48% | 12.9 | 18 months |

| ESAB | Sweden | ISO, ABS, Lloyd’s | 47% | 12.6 | 18 months |

Custom Solutions for Arc welding electrodes AWS E7024

STEELTOOLSCHINA (est. 1998, ISO 9001 certified, annual capacity 28,000+ tons) offers fully customized services for Arc welding electrodes AWS E7024:

- Diameters: 2.0–6.0mm, length up to 1,000mm (±1mm CNC cut)

- Custom branding (laser logo, QR code, box print), anti-counterfeit tracking

- Special flux blends: higher impact toughness, climate-adaptive coating

- Packaging: 5kg–25kg, vacuum bags, export fiber drums/cartons

- Standards: AWS/ISO/ANSI/BS/EN, 3.1b test certs on request

- OEM, ODM, and expedited delivery (≤21 days for main spec, ex-works)

Application Scenarios: Typical Industry Cases

- Shipbuilding (China Shipyard Group, 2023): AWS E7024 electrodes used in hull panel assembly boosted line productivity by 32% over E6013, achieving ISO 3834 weld compliance and 20% less rework.

- Steel Structure Fabrication: Large-span warehouses and container111 terminal skeletons employ E7024 for their flat fillet performance, reducing weld time by 18% and welders' fatigue by 27% (customer survey, 2022).

- Pressure Vessel Manufacturing: E7024 adopted for horizontal seams in oil tank farms; tests showed superior bead shape with less undercut compared to E7018, meeting API 650 acceptance and ABS inspection standards.

- Metallurgy, Petrochemical: Used in both plant retrofits and greenfield construction, E7024 ensures high deposition, easy slag removal—picked by ArcelorMittal’s East Asia operations for 40% of welds in 2022 (project data).

- Water and Wastewater Treatment Plants: For large pipe manifolds and tanks, resulting in durable, corrosion-resistant seams per EN 12480, reducing leak repairs and extending facility service by up to 4 years.

- Customer Feedback: End-users across 22 countries (2021–2023) report excellent bead appearance, minimal cleaning, and superior productivity.

Delivery, Warranty & Customer Support

- ✔ Lead Time: 7–21 days for main sizes (10M standard rods), 21–35 days for special/customized specs

- ✔ Warranty: 12–24 months against core/coating defects under normal storage and process

- ✔ Technical Support: AWS/ISO certified welding engineers on call for pre-sale, usage, and troubleshooting

- ✔ After-sales: On-site technical visits for major clients, failure root cause analysis, and process optimization

- ✔ Certs: Full ISO 9001, ISO 14001, 3.1b test certificates, ABS/CCS/Lloyd’s/DNV third-party inspection (on request)

- ✔ Traceability: Batch-level tracking (QR/barcode), document retention for 5+ years

- ✔ OEM/ODM: Complete solution for branding/private label and specification flexibility

Professional FAQ on Arc welding electrodes AWS E7024

References & Further Reading

- Grand View Research: Global Welding Consumables Market Report

- IHS Engineering360: AWS A5.1/A5.1M Electrode Specification

- IIW Bulletin: Arc Welding Electrodes Performance 2023 ICCW/IIW Publications

- Practical Welding Today Forum: User Feedback & Field Testing

- ISO Official: ISO 2560-A Standard

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025