Feb . 19, 2025 04:23

Back to list

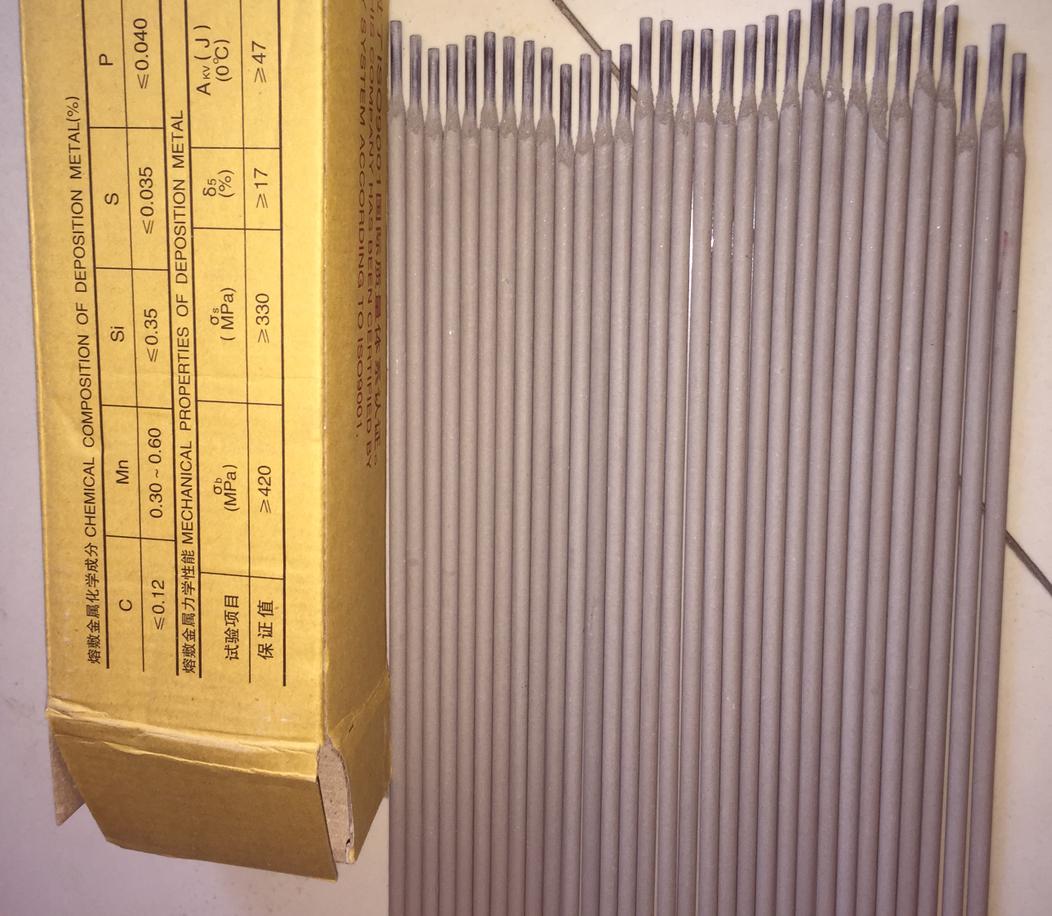

aws e6013 welding electrodes

Precision and consistency are paramount when it comes to TIG welding, and choosing the right electrodes is crucial for ensuring optimal performance. Among the various types of electrodes vital for TIG welding processes, those manufactured in China have gained significant traction in the global market. China’s TIG welding electrodes are well-regarded for their quality, cost-effectiveness, and innovation.

In terms of authoritativeness, Chinese manufacturing companies collaborate extensively with welding professionals worldwide to refine their products. They engage in partnerships with leading research institutions and attend numerous industry conferences to ensure their electrodes incorporate the latest technological advancements and align with global industry standards. This exchange of knowledge not only boosts the credibility of Chinese TIG electrodes but also ensures they remain at the forefront of welding technology. Trustworthiness is another cornerstone of Chinese TIG welding electrodes. Manufacturers prioritize stringent quality assurance practices, often exceeding international safety and performance benchmarks. Moreover, customer support is robust, with many companies offering comprehensive pre- and post-sales services, including technical support and guidance on electronic repeatability and voltage compatibility. Furthermore, Chinese TIG welding electrodes offer remarkable value for money. While maintaining competitive pricing, they do not compromise on quality – a balance achieved by optimizing production processes and sourcing raw materials efficiently. Consequently, they allow businesses worldwide to enhance productivity without inflating operating costs. For those seeking to optimize their TIG welding processes, the choice of electrodes could greatly impact the finish and durability of their workpieces. China’s offerings are rapidly becoming synonymous with reliability and efficiency, providing a solid foundation for both minor repairs and major manufacturing projects. As global demand for high-caliber, cost-effective solutions in TIG welding electrodes continues to rise, this sector will likely see even more innovations stemming from China. Selecting the right electrode is not just about immediate gains but also about long-term results, ensuring that each product not only meets but exceeds user expectations. A comprehensive understanding of why China’s TIG welding electrodes are commanding increasing market attention can provide valuable insights into making informed purchasing decisions that leverage cutting-edge technology and unparalleled expertise in the welding domain.

In terms of authoritativeness, Chinese manufacturing companies collaborate extensively with welding professionals worldwide to refine their products. They engage in partnerships with leading research institutions and attend numerous industry conferences to ensure their electrodes incorporate the latest technological advancements and align with global industry standards. This exchange of knowledge not only boosts the credibility of Chinese TIG electrodes but also ensures they remain at the forefront of welding technology. Trustworthiness is another cornerstone of Chinese TIG welding electrodes. Manufacturers prioritize stringent quality assurance practices, often exceeding international safety and performance benchmarks. Moreover, customer support is robust, with many companies offering comprehensive pre- and post-sales services, including technical support and guidance on electronic repeatability and voltage compatibility. Furthermore, Chinese TIG welding electrodes offer remarkable value for money. While maintaining competitive pricing, they do not compromise on quality – a balance achieved by optimizing production processes and sourcing raw materials efficiently. Consequently, they allow businesses worldwide to enhance productivity without inflating operating costs. For those seeking to optimize their TIG welding processes, the choice of electrodes could greatly impact the finish and durability of their workpieces. China’s offerings are rapidly becoming synonymous with reliability and efficiency, providing a solid foundation for both minor repairs and major manufacturing projects. As global demand for high-caliber, cost-effective solutions in TIG welding electrodes continues to rise, this sector will likely see even more innovations stemming from China. Selecting the right electrode is not just about immediate gains but also about long-term results, ensuring that each product not only meets but exceeds user expectations. A comprehensive understanding of why China’s TIG welding electrodes are commanding increasing market attention can provide valuable insights into making informed purchasing decisions that leverage cutting-edge technology and unparalleled expertise in the welding domain.

Previous:

Latest news

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025