High-Quality Flux-Cored Welding Wire Manufacturer | Reliable Solutions for Your Welding Needs

The Evolution and Importance of Flux-Cored Welding Wire Factories

In the world of welding, the type of wire used plays a critical role in determining the quality and efficiency of the welding process. Among the diverse options available, flux-cored welding wire has gained prominence for its versatility and effectiveness, particularly in environments that require high deposition rates and strong welds. The factories that produce this specialized welding wire contribute significantly to both industrial applications and the overall manufacturing ecosystem.

The Evolution and Importance of Flux-Cored Welding Wire Factories

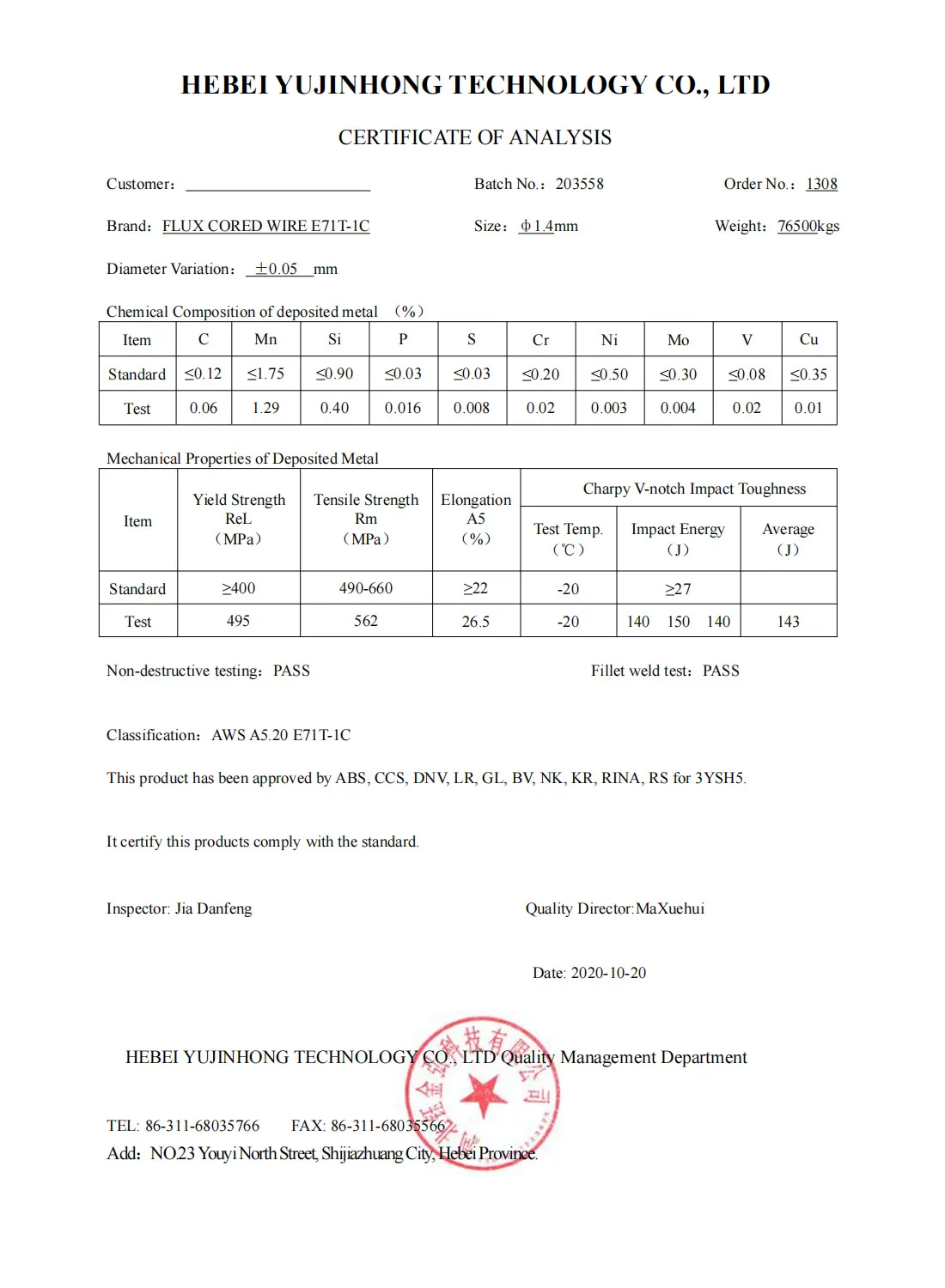

The production of flux-cored welding wire begins with the selection of raw materials. Factories meticulously source high-grade steel and other alloying elements to create wires that can withstand various welding applications. The wire is then drawn to specific gauges, ensuring consistency and reliability. One of the key factors that separate a reputable factory from the rest is its commitment to quality control. Rigorous testing and inspection processes are essential to verify that the finished product meets industry standards and customer specifications.

flux-cored welding wire factory

Modern flux-cored welding wire factories utilize automation and advanced machinery to streamline the manufacturing process. This not only enhances production efficiency but also reduces labor costs, allowing for competitive pricing in the market. Furthermore, these technologies enable factories to produce a wider variety of welding wires tailored to specific applications, such as high-strength structures, pipe welding, and fabrication work.

Sustainability has become an increasingly important consideration in modern manufacturing. Many flux-cored welding wire factories are adopting eco-friendly practices by recycling scrap metal and reducing waste through optimized production methods. This commitment to sustainability not only benefits the environment but also appeals to customers who prioritize responsible sourcing and production practices.

The role of flux-cored welding wire factories is not limited to production alone. They play an essential part in the broader welding industry by collaborating with researchers and engineers to develop new formulations and welding techniques. This collaborative spirit fosters innovation and leads to the creation of products that meet the ever-evolving needs of various sectors, including construction, automotive, shipbuilding, and energy.

In conclusion, flux-cored welding wire factories are vital components of the welding industry, providing essential materials that enhance the effectiveness and quality of welding processes. Their focus on innovation, quality control, and sustainability ensures that they not only meet current demands but also pave the way for advancements in welding technology. As the industry continues to evolve, these factories will remain at the forefront, adapting to new challenges and contributing to the growth and development of the manufacturing sector worldwide.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025