wholesale 6010 welding electrodes factory

The Future of Welding Innovations in Wholesale 6010 Welding Electrodes

Welding electrodes are vital components in the welding process, serving as the medium that conducts current to create a molten weld pool. Among the various types of electrodes available in the market, the E6010 welding electrode has gained significant popularity, particularly in the wholesale sector. This article delves into the nuances of wholesale E6010 welding electrodes, their applications, advantages, and the future trajectory of the welding industry.

Understanding E6010 Welding Electrodes

E6010 is a type of stick electrode often used for welding in different positions. It belongs to the category of cellulosic electrodes, which contain a high cellulose content in their coating. This unique property makes them particularly suited for fast welding and deep penetration in root passes, especially when working with dirty or rusty metals. E6010 electrodes are commonly used in industries like construction, shipbuilding, and pipeline welding due to their strength and versatility.

The Wholesale Market Landscape

The wholesale market for E6010 welding electrodes has seen significant growth, driven by the increasing demand for high-quality welding solutions across various sectors. Manufacturers and suppliers are focusing on bulk production to meet the needs of construction companies, repair shops, and industrial plants that depend on a steady supply of welding materials.

One of the main benefits of purchasing E6010 electrodes wholesale is cost efficiency. Buying in bulk typically reduces the overall cost per unit, making it a more economical option for businesses. Additionally, wholesalers often provide a wider selection of products, ensuring that customers can find the specific type of electrode suitable for their welding tasks.

Advantages of E6010 Electrodes

The E6010 welding electrode offers several advantages that have made it a favorite among welders

1. Deep Penetration The E6010 provides excellent arc stability, resulting in deeper penetration into the base metal. This characteristic is crucial when welding thick materials or in challenging positions.

wholesale 6010 welding electrodes factory

2. Versatility E6010 electrodes can be used in various applications, including root passes and overhead welding. Welders often appreciate their versatility, making them suitable for both inexperienced and skilled operators.

3. Good Arc Control The cellulosic coating allows for excellent arc control, minimizing spatter and ensuring a clean weld pool. This attribute aids in producing high-quality welds that are strong and uniform.

4. Adaptability to Different Conditions E6010 electrodes are effective in areas with less-than-ideal cleanliness, making them ideal for job sites where surfaces may be contaminated.

5. Ease of Use Due to their forgiving nature, E6010 electrodes are easier to manipulate for welders, allowing for better control over the welding process.

Innovations and Future Trends

As the demand for E6010 welding electrodes grows, the industry is witnessing innovations aimed at enhancing performance. Research into the formulation of electrode coatings is ongoing, with the goal of improving arc stability, reducing fume emissions, and increasing usability across various environments.

Moreover, advancements in automation and welding technology are shifting the landscape. The integration of robotics in welding processes is becoming increasingly prevalent. Manufacturers are adapting their electrode designs to enhance compatibility with automated systems, ensuring consistent quality and efficiency in production.

Sustainability is another critical factor influencing the future of the welding industry. Manufacturers are exploring eco-friendly alternatives in electrode production, aiming to minimize environmental impact without compromising performance. This trend aligns with global efforts to reduce carbon footprints and promote sustainable practices across industries.

Conclusion

The wholesale market for E6010 welding electrodes plays a pivotal role in meeting the demands of modern welding applications. With their unique advantages and growing demand, E6010 electrodes are set to maintain their position as a staple in the welding industry. As innovations continue to emerge, the future looks bright for both manufacturers and welders alike, promising enhanced performance and a stronger focus on sustainability. The continued evolution of this essential product will not only improve welding quality but also pave the way for more efficient and eco-friendly practices in the years to come.

-

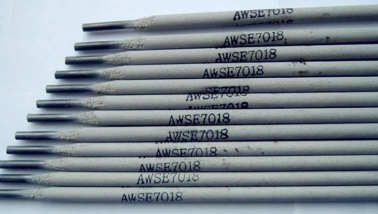

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025