Your Trusted Welding Electrode and Rod Manufacturer

In today’s industrial landscape, welding is the foundation of infrastructure and innovation. From construction to shipbuilding, automotive to energy production, the quality of welding consumables directly determines the integrity and performance of countless structures and systems. That’s why choosing a reputable welding electrode manufacturer or welding rod supplier is not just a purchasing decision—it’s an investment in safety, efficiency, and long-term success. As a seasoned welding rod manufacturer with nearly three decades of experience, we understand the evolving needs of global industries and provide high-performance welding solutions tailored to meet every demand.

A Legacy of Excellence in Welding Consumables

Since our establishment in 1996, we have grown into a trusted name among global buyers looking for a professional welding electrode supplier. Headquartered in the industrious northern Chinese city of Shijiazhuang, we have combined tradition with innovation to build a comprehensive supply chain that meets both domestic and international welding standards. Our manufacturing facility, spanning over 1,200,000 square meters and employing more than 500 skilled workers, stands as a testament to our commitment to large-scale production with precision quality.

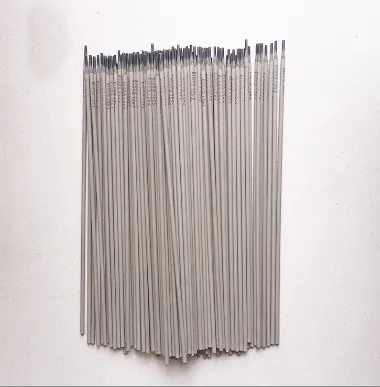

Over the years, we’ve specialized in developing and distributing a full range of welding consumables, including E6013, E6010, E6011, E7016, and E7018 welding rods. Each product is engineered with accuracy and tested rigorously for performance across a variety of welding applications. Whether you're working with structural steel, pipelines, stainless materials, or cast iron, our offerings are crafted to provide optimal arc stability, easy slag removal, and consistent penetration—qualities that every welder counts on.

Comprehensive Product Lines for Diverse Applications

Our strength as a welding rod manufacturer lies in our extensive product line that serves both general and specialized welding requirements. We produce carbon steel electrodes, stainless steel electrodes, low-hydrogen electrodes, and high-tensile strength electrodes, all under strict quality controls and international standards. These include E6013 rods for light to medium fabrication, E7018 rods for high-strength structural applications, and E7016 rods for welding pressure vessels and pipelines.

In addition to our core rod offerings, we are also a leading welding electrode manufacturer of advanced consumables such as cast iron welding rods and stainless steel electrodes, providing solutions for challenging welding tasks involving dissimilar metals, high heat zones, or repair work. Furthermore, our flux-cored wire and ER70S-6 welding wire expand the capabilities of MIG and TIG operations, ensuring we meet the demands of both manual and automated welding systems.

Our products have been approved by ten international classification societies, including ABS, BV, CCS, DNV, LR, NK, KR, RINA, RS, and BKI, which demonstrates our capacity to meet rigorous global certification standards. These recognitions are more than credentials—they are proof of trust from the maritime, oil & gas, construction, and manufacturing industries around the world.

Global Reach with Local Expertise

As a globally recognized welding electrode supplier, our footprint extends far beyond China's borders. Through our renowned “GREAT MASTER” brand, we have developed a robust international sales network that connects us with clients in Europe, Southeast Asia, South America, the Middle East, and Africa. Our distribution strategy prioritizes efficiency, customer satisfaction, and supply reliability, enabling us to deliver products promptly and consistently, regardless of destination.

At home, our presence spans every province in China, enabling industries across the nation to benefit from our high-quality welding solutions. Abroad, we engage with clients through customized service plans, including OEM and private labeling, to support regional branding and regulatory compliance. Every product shipped from our facility comes with detailed technical support, batch tracking, and post-sale consultation.

With multilingual sales teams and international logistics capabilities, we ensure that our clients receive the same level of expertise and attentiveness no matter where they are located. We believe in forming lasting partnerships, and that begins with understanding the specific challenges our clients face and offering welding consumables that not only meet their requirements but exceed expectations.

Quality Assurance through Certifications and Standards

When it comes to welding, quality control is non-negotiable. As a certified welding rod supplier holding ISO 9001 for quality management, ISO 14001 for environmental standards, and ISO 50001 for energy management, we ensure that each aspect of our operation is governed by transparency, accountability, and excellence. These certifications signify not only our adherence to global benchmarks but also our internal dedication to sustainable and responsible manufacturing.

Our quality assurance process includes raw material inspection, process monitoring, mechanical property testing, and performance evaluation. Each batch of welding electrodes or welding rods is tested under simulated field conditions to verify tensile strength, elongation, deposition rate, and weld bead appearance. By investing in automated production lines, precision testing equipment, and skilled personnel, we eliminate variability and maximize reliability.

We also provide detailed Material Safety Data Sheets (MSDS) and technical specifications with every shipment to ensure safe and correct usage. Clients in regulated industries such as aerospace, shipbuilding, or energy can trust that our products will meet both performance and safety requirements. Our ability to deliver consistent quality has made us the preferred welding electrode manufacturer for high-risk applications where failure is not an option.

Welding Electrode Manufacturer FAQs

What makes your welding electrodes different from other suppliers?

As a long-standing welding electrode manufacturer, we place a strong emphasis on consistent product quality and rigorous quality control processes. Unlike some mass-market alternatives, our electrodes are produced using high-purity raw materials, advanced formulation technologies, and multi-step inspection protocols. We ensure every electrode offers smooth arc characteristics, minimal spatter, and high deposition efficiency, helping welders achieve better results with less effort.

Can you provide custom branding or OEM welding rods?

Yes, we offer OEM services for clients looking to market their own welding consumable brand. As a trusted welding rod supplier, we provide flexible packaging solutions, private labeling, and branding support tailored to your regional market preferences. Whether you require small-scale packaging for retail distribution or industrial bulk supply, we can accommodate your specific needs without compromising on product quality.

What types of welding rods are best for structural steel fabrication?

For structural steel applications, E7018 and E7016 electrodes are highly recommended due to their low hydrogen content, high tensile strength, and superior crack resistance. As an experienced welding rod manufacturer, we produce these rods in compliance with AWS and ISO standards, ensuring they perform reliably even under heavy load-bearing conditions. Their excellent arc stability and weld bead appearance make them ideal for bridges, buildings, and infrastructure projects.

Do your products meet international safety and performance standards?

Absolutely. Our welding electrodes and rods have received approvals from globally recognized classification societies such as ABS, DNV, and LR. In addition, we are certified under ISO 9001, ISO 14001, and ISO 50001. These certifications reflect our status as a top-tier welding electrode supplier committed to meeting the most demanding international safety, environmental, and energy standards.

How can I choose the right welding electrode for my project?

Selecting the right electrode depends on factors like base metal type, welding position, desired strength, and operating environment. Our experienced engineers and sales team are always available to assist you in selecting the best option from our broad range of electrodes, whether you’re working with carbon steel, stainless steel, or cast iron. As your professional welding rod supplier, we offer detailed product datasheets and personalized consultations to ensure you achieve optimal welding results.

-

What is a medium-frequency pulse? What types of welding are suitable for?BeritaNov.24,2025

-

Why is the overall cost of CO2 welding lower than that of shielded metal arc welding?BeritaNov.21,2025

-

Welding Knowledge 6BeritaNov.20,2025

-

What is a low-frequency pulse? What types of welding are they suitable for?BeritaNov.19,2025

-

Why are the weld joints from CO₂ gas shielded welding of such high quality?BeritaNov.18,2025

-

J506 Welding Rod - Low Hydrogen, All-Position, AC/DC E7016BeritaNov.17,2025