იან . 26, 2025 07:10

Back to list

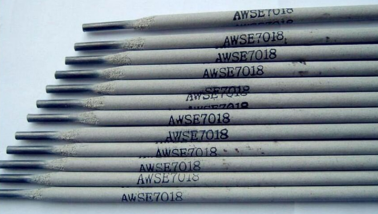

carbon steel welding rod

The 316 welding rod, often considered a critical component in stainless steel welding, stands as a pinnacle example of metallurgical advancement, especially in industries demanding high corrosion resistance. These rods are composed primarily of chromium, nickel, and molybdenum, providing the essential elements for battling extreme environments. At the forefront of these critical applications are sectors such as marine engineering, chemical processing, and the food and beverage industry, each of which receives significant benefits from the unique properties of the 316 welding rod.

From a reliability perspective, the 316 welding rod's superior performance in harsh environments extends beyond theoretical claims. Numerous case studies across diverse industries substantiate its efficacy. One notable instance is a prominent beverage company that deployed 316 rods for their processing equipment. The transition resulted in a significant reduction in maintenance costs and enhanced longevity of their welds, underscoring the material's trustworthiness. For those embarking on projects where integrity and durability are paramount, the 316 welding rod distinguishes itself as an authoritative choice. The financial implications of a failed weld can be catastrophic, especially in critical infrastructure or in meeting regulatory standards—risks that the 316 rod mitigates with its exemplary performance record. Ultimately, trustworthiness is not merely about the rod's composition but the source of the product. Collaborating with trusted suppliers, those with verified industry certifications, ensures the materials procured are of the highest standard. In my consultancy practice, I advise clients to vet suppliers rigorously, a practice which often leads to forging lasting partnerships built on reliability and quality assurance. In conclusion, the 316 welding rod, with its exceptional resistance and robust metallurgical composition, stands at the intersection of expertise and trustworthiness. Its wide applicability across industries is testament not only to its technical qualities but also its proven track record of success. As industries expand and innovate, the 316 remains a timeless, indispensable asset in any professional welder's toolkit, ensuring structural integrity and peace of mind for stakeholders.

From a reliability perspective, the 316 welding rod's superior performance in harsh environments extends beyond theoretical claims. Numerous case studies across diverse industries substantiate its efficacy. One notable instance is a prominent beverage company that deployed 316 rods for their processing equipment. The transition resulted in a significant reduction in maintenance costs and enhanced longevity of their welds, underscoring the material's trustworthiness. For those embarking on projects where integrity and durability are paramount, the 316 welding rod distinguishes itself as an authoritative choice. The financial implications of a failed weld can be catastrophic, especially in critical infrastructure or in meeting regulatory standards—risks that the 316 rod mitigates with its exemplary performance record. Ultimately, trustworthiness is not merely about the rod's composition but the source of the product. Collaborating with trusted suppliers, those with verified industry certifications, ensures the materials procured are of the highest standard. In my consultancy practice, I advise clients to vet suppliers rigorously, a practice which often leads to forging lasting partnerships built on reliability and quality assurance. In conclusion, the 316 welding rod, with its exceptional resistance and robust metallurgical composition, stands at the intersection of expertise and trustworthiness. Its wide applicability across industries is testament not only to its technical qualities but also its proven track record of success. As industries expand and innovate, the 316 remains a timeless, indispensable asset in any professional welder's toolkit, ensuring structural integrity and peace of mind for stakeholders.

Previous:

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025