იან . 13, 2025 09:34

Back to list

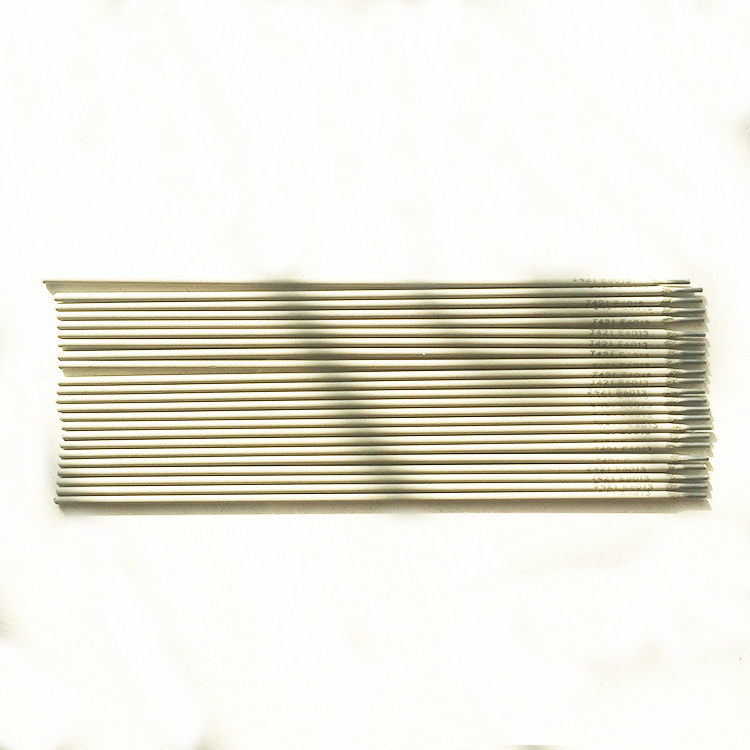

China welding rod 6013 welding electrodes aws e6013

Choosing the right welding equipment is crucial for achieving reliable and durable welds, particularly in demanding industrial applications. One of the most reliable options for exceptional welding results is the 6010 welding electrode. Known for its versatility and robustness, the 6010 electrode is a staple in various sectors ranging from construction to manufacturing.

Furthermore, trustworthiness is supported by a legacy of performance in extreme environments. Frequent testimonials from welders working on critical infrastructure, such as bridges and high-rise buildings, reinforce the confidence in 6010 electrodes. Their intrinsic reliability, evidenced by decades of consistent industry usage, makes them indispensable in environments where mortal safety and structural soundness are paramount. When selecting 6010 electrodes, it's essential to pair them with the right power source, typically direct current (DC) machines, set to reverse polarity (DC+). This setup enhances the penetration effect and optimizes the performance of the electrode, allowing for clean and effective welds. It's also noteworthy that quality varies among manufacturers. Therefore, selecting reputable brands known for uncompromised electrode quality is vital. Manufactures often test these products under rigorous conditions to ensure their electrodes meet or exceed industry standards. Investing in superior quality electrodes can significantly impact the professionalism and durability of your welding projects. For welding professionals or enthusiasts aiming to enhance their skills, it is beneficial to seek out workshops or courses focusing specifically on 6010 electrodes. Engaging with communities or forums dedicated to welding can also provide valuable insights and tips shared by seasoned welders. In conclusion, the 6010 welding electrode is a powerful tool in the hands of a skilled operator. Its exceptional capabilities in penetration, handling of varied positions, and adaptability across numerous materials affirm its status as a top choice for heavy-duty welding tasks. When wielded with expertise, it guarantees not only the success of the weld but also the long-term reliability of the structures it helps create.

Furthermore, trustworthiness is supported by a legacy of performance in extreme environments. Frequent testimonials from welders working on critical infrastructure, such as bridges and high-rise buildings, reinforce the confidence in 6010 electrodes. Their intrinsic reliability, evidenced by decades of consistent industry usage, makes them indispensable in environments where mortal safety and structural soundness are paramount. When selecting 6010 electrodes, it's essential to pair them with the right power source, typically direct current (DC) machines, set to reverse polarity (DC+). This setup enhances the penetration effect and optimizes the performance of the electrode, allowing for clean and effective welds. It's also noteworthy that quality varies among manufacturers. Therefore, selecting reputable brands known for uncompromised electrode quality is vital. Manufactures often test these products under rigorous conditions to ensure their electrodes meet or exceed industry standards. Investing in superior quality electrodes can significantly impact the professionalism and durability of your welding projects. For welding professionals or enthusiasts aiming to enhance their skills, it is beneficial to seek out workshops or courses focusing specifically on 6010 electrodes. Engaging with communities or forums dedicated to welding can also provide valuable insights and tips shared by seasoned welders. In conclusion, the 6010 welding electrode is a powerful tool in the hands of a skilled operator. Its exceptional capabilities in penetration, handling of varied positions, and adaptability across numerous materials affirm its status as a top choice for heavy-duty welding tasks. When wielded with expertise, it guarantees not only the success of the weld but also the long-term reliability of the structures it helps create.

Latest news

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025