იან . 20, 2025 15:49

Back to list

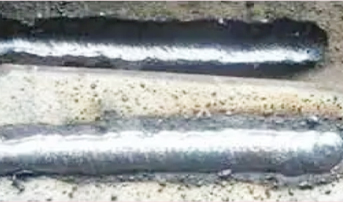

ER70S-6 Co2 Solid Mig Welding Wire

The welding industry, recognized for its dynamic development and emphasis on advancing technology, tends to lean heavily on specialty products that accentuate precision and durability. One such product that continues to gain traction is the 0.9 mm ER70S-6 welding wire. This specific grade is distinguished by its optimal composition and formidable performance across various applications, making it a preferred choice among industry professionals.

The authoritative nature of 0.9 mm ER70S-6 welding wire is not merely a testament to user preference but also to endorsements from welding equipment manufacturers and standards organizations. It meets specifications, notably the American Welding Society’s (AWS) A5.18 standard, underlining its compliance with quality and safety benchmarks crucial for various welding tasks. Such validations reaffirm the wire’s reliability and the trust that professionals place in it for their critical applications. Trustworthiness in selecting this welding wire extends beyond technical specifications; it resides within user testimonies and documented successes. Fabricators share experiences where the utilization of ER70S-6 has afforded them reduced downtimes and increased satisfaction in end-product durability. Even in challenging situations like structural repairs or high-volume productions, this wire has demonstrated an ability to deliver consistency and performance that engineers and contractors consistently rely upon. In conclusion, when considering a welding wire that balances exceptional performance with cost-effectiveness, the 0.9 mm ER70S-6 weld wire emerges as an industry favorite. Not only does it fulfill the specific needs of modern-day welders striving for perfection in their craft, but it also symbolizes a material investment in quality and precision that reverberates across myriad applications. The interplay of experience, expertise, authority, and trustworthiness presents this specific welding wire as not just another consumable, but as a cornerstone of effective and reliable welding practice.

The authoritative nature of 0.9 mm ER70S-6 welding wire is not merely a testament to user preference but also to endorsements from welding equipment manufacturers and standards organizations. It meets specifications, notably the American Welding Society’s (AWS) A5.18 standard, underlining its compliance with quality and safety benchmarks crucial for various welding tasks. Such validations reaffirm the wire’s reliability and the trust that professionals place in it for their critical applications. Trustworthiness in selecting this welding wire extends beyond technical specifications; it resides within user testimonies and documented successes. Fabricators share experiences where the utilization of ER70S-6 has afforded them reduced downtimes and increased satisfaction in end-product durability. Even in challenging situations like structural repairs or high-volume productions, this wire has demonstrated an ability to deliver consistency and performance that engineers and contractors consistently rely upon. In conclusion, when considering a welding wire that balances exceptional performance with cost-effectiveness, the 0.9 mm ER70S-6 weld wire emerges as an industry favorite. Not only does it fulfill the specific needs of modern-day welders striving for perfection in their craft, but it also symbolizes a material investment in quality and precision that reverberates across myriad applications. The interplay of experience, expertise, authority, and trustworthiness presents this specific welding wire as not just another consumable, but as a cornerstone of effective and reliable welding practice.

Next:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025