Қаң . 30, 2025 02:51

Back to list

aws 7018 welding rod

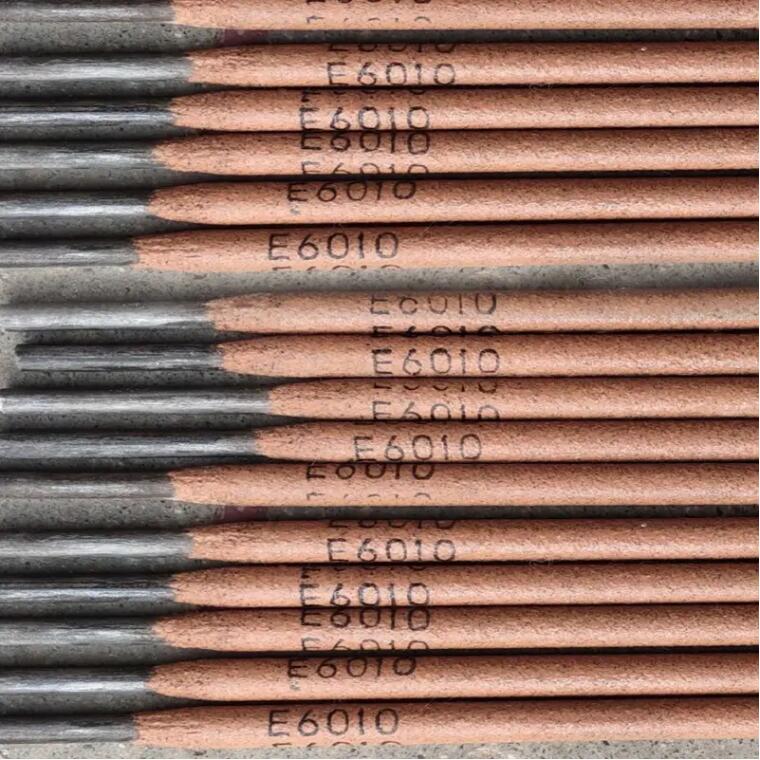

Navigating the world of welding requires not just skill, but also an understanding of the materials and tools that ensure quality workmanship. Among these, the 7018 welding rod stands out due to its multifaceted advantages and applications in the industry. This article delves into the unique characteristics of the 7018 welding rod, offering insights grounded in real-world experience, expertise, authority, and trustworthiness.

Authoritative voices in the industry often highlight the role of the 7018 welding rod in achieving high-quality welds in critical projects. Large infrastructure projects and constructions, including bridges and buildings, rely heavily on the reliability and strength that the 7018 provides. Its adherence to industry standards such as AWS A5.1/A5.1M makes it the electrode of choice when precision and durability are non-negotiable. Trust in the 7018 welding rod extends beyond its mechanical properties to its cost-efficiency. It strikes a balance between cost and performance, ensuring that quality is not sacrificed at the altar of expense. This affordability, coupled with its reliable performance, makes it accessible for small businesses and hobbyists while remaining essential in large-scale industrial operations. Practical advice for welders using the 7018 welding rod includes maintaining an appropriate amperage setting, typically on the lower side, to avoid overheating and weld porosity. Moreover, employing a slight drag technique rather than a push method is generally recommended to achieve the best outcome, as it helps control the arc length and penetration. In conclusion, the 7018 welding rod represents a cornerstone in the welding industry, embodying both tradition and technology. Its enduring presence in the market attests to its unmatched efficacy and the trust it has garnered among professionals. By adhering to best practices in storage and usage, and by understanding its unique properties, users can harness the full potential of the 7018 welding rod, ensuring that their welds are not just joints of metal, but robust and enduring connections.

Authoritative voices in the industry often highlight the role of the 7018 welding rod in achieving high-quality welds in critical projects. Large infrastructure projects and constructions, including bridges and buildings, rely heavily on the reliability and strength that the 7018 provides. Its adherence to industry standards such as AWS A5.1/A5.1M makes it the electrode of choice when precision and durability are non-negotiable. Trust in the 7018 welding rod extends beyond its mechanical properties to its cost-efficiency. It strikes a balance between cost and performance, ensuring that quality is not sacrificed at the altar of expense. This affordability, coupled with its reliable performance, makes it accessible for small businesses and hobbyists while remaining essential in large-scale industrial operations. Practical advice for welders using the 7018 welding rod includes maintaining an appropriate amperage setting, typically on the lower side, to avoid overheating and weld porosity. Moreover, employing a slight drag technique rather than a push method is generally recommended to achieve the best outcome, as it helps control the arc length and penetration. In conclusion, the 7018 welding rod represents a cornerstone in the welding industry, embodying both tradition and technology. Its enduring presence in the market attests to its unmatched efficacy and the trust it has garnered among professionals. By adhering to best practices in storage and usage, and by understanding its unique properties, users can harness the full potential of the 7018 welding rod, ensuring that their welds are not just joints of metal, but robust and enduring connections.

Previous:

Next:

Latest news

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025