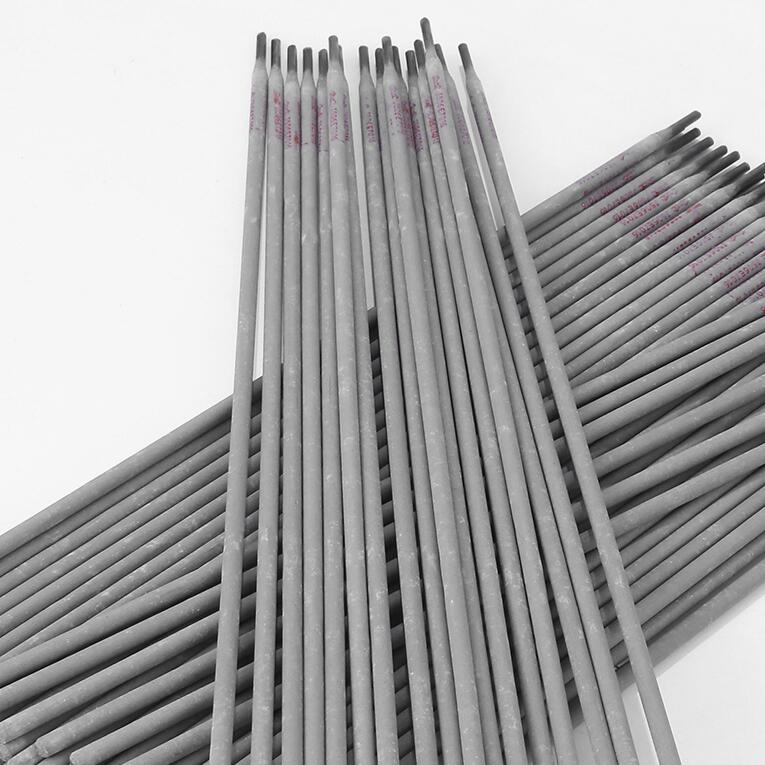

Production Description

Iron powder type basic electrode

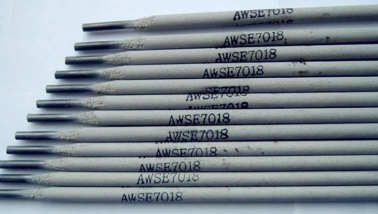

GB/T 5117 E5018

AWS A5.1 E7018

ISO 2560-B-E4918 A

AWS E7018 is basic coated iron powder low potassium hydrogen type electrode. Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, good arc stiffness,little spatter, easy slag removal and good weld appearance,high deposition efficiency.Weld metal has excellent plasticity and low temperature toughness

It can improve deposition efficiency because of the iron powder in the coating. Its arc is more stable with less spatter.It is easy to remove the residue. It can provide both beautiful welding line shape and good deposited metal mechanical performance.And the current can be AC or DC.It can be used for all position welding.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF.

X-ray flaw detection: Ⅰ level.

E7018 electrode is a carbon steel electrode with iron powder and low hydrogen potassium coating. Its arc stiffness is good, it is not easy to produce magnetic deflection blowing, the weld is fine and clean, with less spatter, easy to remove slag, and the weld has better low temperature. Toughness and crack resistance, dual-purpose DC, can be welded in all positions.

Any electrode marked with the end number of 5, 6 or 8 belongs to the low hydrogen type electrode. These electrodes are specially formulated to limit the amount of hydrogen in the final weld. Measures to reduce the hydrogen content should focus on cleaning weldments, joint design, and welding discontinuities. When welding with E7018 electrode, in order to prevent hydrogen from being deposited into the weld, the flux on the electrode should be kept dry. Once the package of welding rods is opened, the flux will begin to absorb moisture from the air. Exposure to air for about 4 hours, the performance of the flux coating will be impaired. If this happens, the electrode will no longer perform as it should, especially when welding high-strength and low-alloy steels. If you are using an electrode with the new H4R suffix, it will hold up well in air for 9h instead of 4h.

Since the E7018 welding rod is easy to absorb moisture, it is stored in a welding rod drying oven. The electrodes stored in the air can be re-baked at 350-400°C for 1h-2h. In order to restore the performance of its drug skin. Mild steel can be welded with unbaked E7018 electrodes, but the weld strength may not be high enough.

Chemical Composition:

|

C |

Mn |

Si |

S |

P |

|

≤0.12 |

≤1.6 |

≤0.75 |

≤0.035 |

≤0.035 |

Mechanical Property:

|

AWS A5.1 |

Tensile Strength Rm |

Yield Strength Rel |

Elongation A |

Akv |

KV2 |

|

MPa |

MPa |

% |

J |

0 degree/J |

|

|

E7018 |

≥490 |

≥400 |

≥22 |

≥27 |

-30 |

Specification & Package

2.5mm (3/32”) x 300/350mm; 2.5kgs/box, 20kg(8boxes) per carton.

3.2mm (1/8”) x 350mm; 5kgs/box, 20kg(4boxes) per carton.

4.0mm (5/32”) x 400mm; 5kgs/box, 20kg(4boxes) per carton.

5.0mm x 450mm; other size please contact our service.

OEM/ODM Package Available:

NW: 20.00KG, GW: 20.40KG,

we also can do different kgs package, plastic bag package,

we can print the package as your requests, we have professional designer to make the package design with your brand & LOGO.

Product Video

Visit & Exhibition

Welcome to visit us for a friendly and long term cooperation, please tell us your time schedule, we will arrange for you. we will also join the relate exhibitions, we can meet each other on the exhibition. Friendship first, and business is professional, you can trust us forever.

Do you have the following trouble when order the products?

1.Is the Supplier Reliable?

We produce this products more than 30 years, we have advertise on Alibaba, Made-in-China, after you place the order, whenever you want to see the production, we can send you video or picture to check. Our export team also have more than 15 years experience, we can solve all the problem you may meet in business. Welcome to visit us.

2.Is the Quality Stable?

We do test randomly in production, and test shipment before ex works. We have professional QC workers and high level test equipment, to assure each shipment in good quality.

3.Is the Payment Safe?

We choose one of the largest bank in China, to assure your payment will arrive in safe condition, and all of the benefit company must send them the shipping document copy to bank for record.

4.Shipment Delivery?

Normally we can arrange shipment in 15 days, if customize the package, shipment can be arranged in one month, please negotiate with our customer service, we will tell you a firm date after check our production and your order quantity.

Please don't hesitate to contact us

Sales Manager: Cherry Zhang

Tel: 0086-311-68035766

Fax: 0086-311-68035566

Mobile: 008613739727566

WhatsApp / Wechat: 008613739727566

Email: info@steeltoolschina.com

Send inquiry