aluminium welding wire manufacturers

The Landscape of Aluminium Welding Wire Manufacturers

Aluminium welding wire is an essential component in various industries, from automotive to aerospace, thanks to its excellent properties such as corrosion resistance, lightweight, and strength. As the demand for high-quality aluminium welding products continues to rise, the role of aluminium welding wire manufacturers becomes increasingly significant.

Understanding Aluminium Welding Wire

Aluminium welding wire is primarily used for welding aluminum components. It is available in various forms, including solid wire and flux-cored wire, which cater to different welding processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. The choice of wire often depends on the specific application, with factors such as the alloy type and desired mechanical properties influencing the decision.

The Importance of Manufacturers

Manufacturers specializing in aluminium welding wire play a crucial role in ensuring the quality and reliability of the end product. These companies utilize advanced technologies and stringent quality control measures to produce welding wires that meet international standards. High-quality welding wires minimize the risk of defects and ensure strong, durable welds, which are critical in applications where safety and structural integrity are paramount.

Market Trends

aluminium welding wire manufacturers

The global aluminium welding wire market has witnessed significant growth in recent years, driven by the increasing use of aluminium in various sectors. The automotive industry, for instance, is shifting towards lighter materials to enhance fuel efficiency. Additionally, the aerospace sector is increasingly adopting aluminium for its lightweight properties coupled with high strength. These trends have led to an uptick in demand for reliable and efficient aluminium welding solutions.

Key Players in the Industry

Several prominent manufacturers dominate the aluminium welding wire market. Companies like Lincoln Electric, ESAB, and Hobart have established themselves as leaders by consistently delivering high-quality products. These manufacturers often invest in research and development to innovate and improve their welding wire offerings, addressing the evolving needs of their clients.

Challenges Faced by Manufacturers

While the aluminium welding wire market presents numerous opportunities, manufacturers also face several challenges. Fluctuating raw material prices can impact production costs, making it necessary for manufacturers to adopt strategic sourcing practices. Additionally, the increasing emphasis on sustainability and environmental responsibility compels manufacturers to consider eco-friendly practices in their operations.

Conclusion

In conclusion, aluminium welding wire manufacturers are crucial to the growth and development of industries that rely on welding technology. By providing high-quality welding wires, these manufacturers contribute significantly to the performance and durability of welded structures across various applications. As the market continues to expand and evolve, manufacturers will need to adapt to changing demands, ensuring that they produce innovative and sustainable solutions for their clients. With ongoing advancements in technology and materials, the future of aluminium welding wire manufacturing looks promising, holding the potential for improved products and enhanced safety standards in welding applications worldwide.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

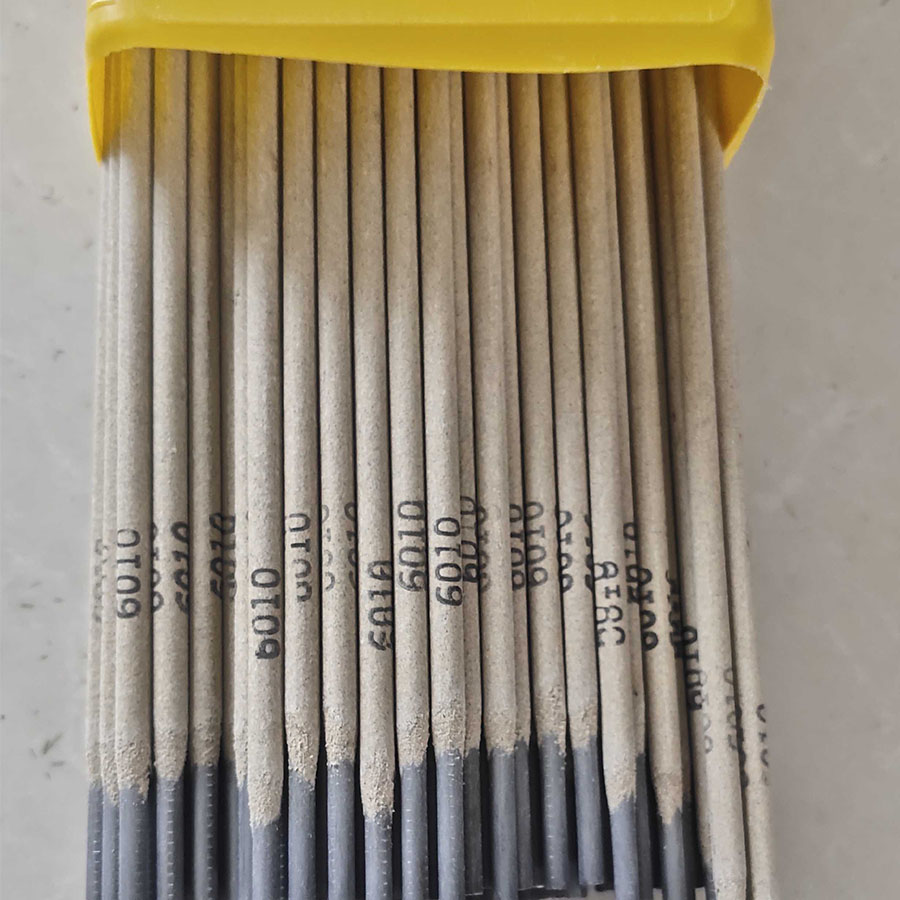

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025