E6010 Cellulose Electrode: Deep Penetration Steel Welding Rod

In the demanding world of industrial fabrication, particularly within pipeline construction and general structural welding, the choice of welding electrode is paramount. Among the vast array of options, the cellulose electrode E6010 stands out as a true workhorse. Known for its deep penetrating arc, excellent mechanical properties, and superb usability in all positions, especially vertical down, it is the preferred steel welding electrode for critical applications involving carbon steel pipes. This comprehensive guide delves into the core of E6010, exploring its technical prowess, manufacturing excellence, diverse applications, and why it remains an indispensable tool for welders worldwide.

1. Industry Trends and the Enduring Relevance of **Cellulose Electrode E6010**

The global welding industry is continuously evolving, driven by advancements in materials science, automation, and a constant push for greater efficiency and safety. Despite the emergence of advanced welding processes like Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW), the shielded metal arc welding (SMAW) or 'stick welding' process, particularly with cellulose electrode E6010, retains its critical role. Its versatility, low equipment cost, portability, and ability to perform well in challenging outdoor conditions (wind, dampness) make it indispensable for field work, pipeline construction, and maintenance. Current trends highlight a continued demand for robust, reliable electrodes capable of deep penetration and excellent root pass capabilities, exactly where E6010 excels.

According to a report by Global Market Insights, the global welding equipment market size was valued at over USD 20 billion in 2022 and is projected to grow significantly, with SMAW electrodes maintaining a substantial share due to their widespread use in construction, oil & gas, and manufacturing sectors. The specific properties of cellulose electrode E6010, such as its high cellulose content (typically 30-50%), which produces a strong, digging arc, ensure its continued prominence as a special welding rod for critical applications.

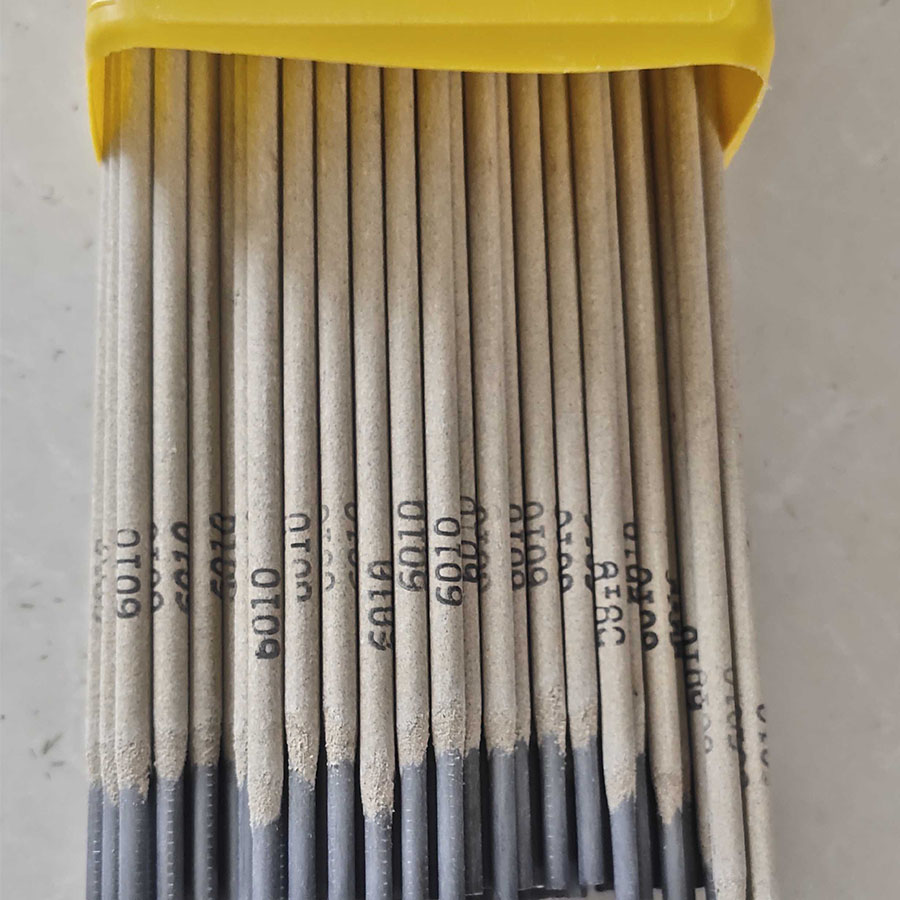

Figure 1: Overview of a modern manufacturing facility for Cellulose Electrode E6010, showcasing precision and scale.

2. Technical Parameters and Specifications of Cellulose Welding Rod E6010

The Cellulose Welding Rod E6010, designed primarily for carbon steel pipes, is an all-position electrode characterized by a deeply penetrating arc and a thin, easily removable slag. Its unique flux composition, rich in cellulose, produces large volumes of gas that shield the molten weld pool from atmospheric contamination. This gas shield also contributes to the forceful, "digging" arc, which is ideal for root passes, especially on pipe. Understanding its technical parameters is crucial for optimal application and performance.

Product Name: Cellulose Welding Rod E6010 for Carbon Steel Pipes

Product URL: https://www.steeltoolschina.com/cellulose-welding-rod-e6010-for-carbon-steel-pipes.html

Key Technical Specifications Table for **Cellulose Electrode E6010** (AWS A5.1 E6010)

| Parameter | Description | Typical Value / Standard | Relevance to Performance |

|---|---|---|---|

| AWS Classification | American Welding Society (AWS) standard designation. | E6010 | Indicates tensile strength (60 ksi), all-position capability, and cellulose-sodium coating. |

| Tensile Strength (min.) | Minimum required tensile strength of the weld metal. | 60 ksi (410 MPa) | Indicates the maximum stress the weld metal can withstand before fracturing. Essential for structural integrity. |

| Yield Strength (min.) | Minimum required yield strength of the weld metal. | 48 ksi (330 MPa) | Point at which material begins to deform plastically. Important for load-bearing applications. |

| Elongation (min.) | Percentage of stretch before fracture. | 22% | Measures ductility, the ability of the material to deform without breaking. Higher values indicate better toughness. |

| Welding Positions | Positions in which the electrode can be used. | All Positions (F, H, V-Up/Down, OH) | Exceptional for vertical down (V-D) welding, common in pipeline root passes. |

| Current Type | Type of welding current required. | DC+ (DCEP - Direct Current Electrode Positive) | Ensures deep penetration, stable arc, and effective cleaning action. |

| Typical Applications | Common industries and uses. | Pipeline (root pass, hot pass), Ship building, Structural steel, General fabrication. | Highlights the electrode's versatility and primary strengths. |

| Slag Type | Characteristics of the slag formed. | Thin, sparse, easily removable | Reduces cleaning time, less slag inclusion risk. |

| Arc Characteristics | Description of the welding arc. | Forceful, "digging," deep penetration | Essential for achieving good fusion, especially on dirty or rusty surfaces. |

| Coating Type | Primary components of the electrode flux. | High Cellulose-Sodium | Generates shielding gases and provides a forceful arc. |

These specifications, verified against industry standards like AWS A5.1/A5.1M:2020 (Specification for Carbon Steel Electrodes for Shielded Metal Arc Welding), confirm the robust performance and reliability of cellulose electrode E6010.

3. Manufacturing Process of **Cellulose Electrode E6010**: Precision from Raw Material to Rod

The quality and performance of cellulose electrode E6010 are directly linked to its meticulous manufacturing process. Unlike conventional electrodes, the high cellulose content requires precise control over mixing, extrusion, and drying to ensure consistent arc characteristics and mechanical properties. Our manufacturing process adheres strictly to international standards such as ISO 9001 for quality management and AWS A5.1 for product specification, ensuring every rod meets stringent performance criteria.

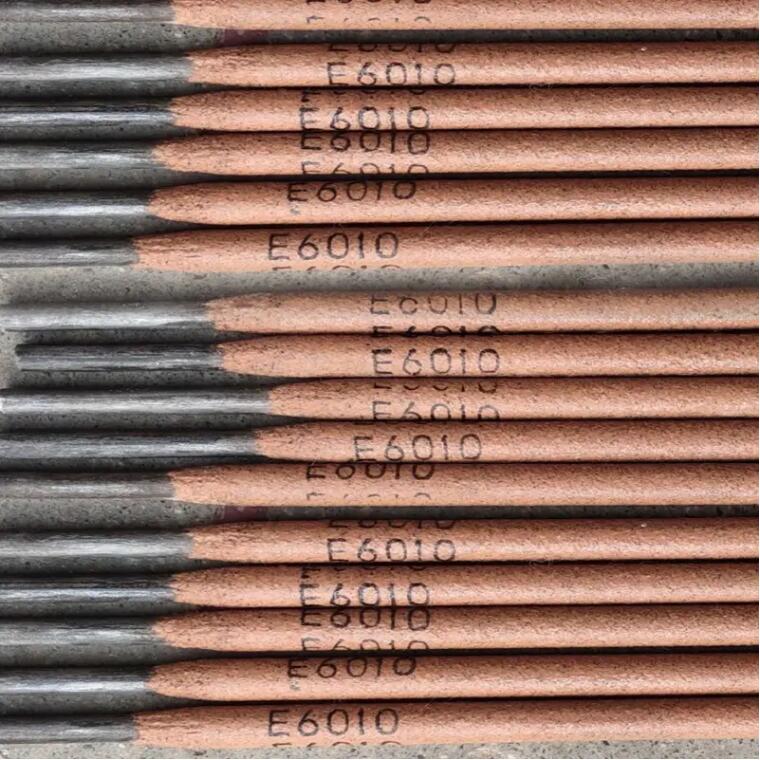

Figure 2: Quality control technicians meticulously inspecting cellulose electrode E6010, ensuring adherence to strict standards.

**Cellulose Electrode E6010** Manufacturing Process Flow

1. Raw Material Preparation & Blending:

High-purity raw materials including cellulose (wood pulp), rutile, ferrosilicon, ferromanganese, and binders are meticulously weighed and blended into a homogeneous mixture. The specific blend ratio is critical for achieving the desired arc characteristics and mechanical properties of the cellulose electrode E6010.

2. Core Wire Preparation:

High-quality steel core wires, typically made from low carbon steel, are cleaned and straightened. The diameter of the core wire must be precise to ensure concentricity during the extrusion process.

3. Extrusion Coating:

The blended flux mixture is extruded onto the core wire under high pressure. This process ensures a uniform and concentric coating thickness around the core wire, a crucial factor for stable arc performance. Modern manufacturing employs advanced extrusion technology for consistent coating.

4. Drying and Baking:

After extrusion, the electrodes undergo a precise drying and baking process in controlled temperature and humidity environments. This step removes moisture from the flux coating, preventing porosity in the weld metal and ensuring optimal moisture resistance for the cellulose electrode E6010. The high cellulose content necessitates careful drying to avoid cracking.

5. End Finishing & Inspection:

Once dried, the electrodes are end-finished (e.g., tip cleaning) and subjected to rigorous quality control inspections. This includes visual checks, dimensional accuracy tests, chemical analysis of the flux, and destructive weld tests (e.g., tensile strength, impact toughness, X-ray inspection of weldments) to ensure the electrodes meet or exceed AWS A5.1 and other relevant standards like ASME Section IX for welder qualification and procedure specification.

6. Packaging:

Finished cellulose electrode E6010 rods are carefully packaged in moisture-resistant materials to protect their integrity during storage and transport, ensuring they arrive on-site ready for immediate use.

4. Application Scenarios and Industries Benefiting from **Cellulose Electrode E6010**

The unique characteristics of **cellulose electrode E6010** make it an ideal choice for a wide range of critical applications, particularly where deep penetration, high travel speeds, and excellent root pass characteristics are paramount. Its ability to handle pipe welding, especially vertical down progression, is unparalleled, making it a staple in numerous heavy industries.

- Oil & Gas Pipelines (API 1104): This is arguably the most dominant application. E6010 is the go-to electrode for root passes on cross-country pipelines, gathering lines, and in-plant piping. Its forceful arc burns through contaminants and provides deep penetration, crucial for achieving full fusion on the root of butt joints in pipes. It's often followed by E7010-G or E7018 for fill and cap passes.

- Petrochemical & Refinery Facilities: For process piping, pressure vessels, and structural components within refineries, chemical plants, and power generation facilities, E6010 provides robust welds capable of withstanding high pressures and temperatures. Its reliability contributes to enhanced safety and operational longevity.

- Shipbuilding & Marine Construction: In shipyards, E6010 is used for general fabrication, structural welding, and pipe connections. Its all-position capability is highly advantageous in the often complex and restricted access environments of shipbuilding.

- Water Supply & Drainage Infrastructure: For large diameter water pipelines, sewage systems, and treatment plants, E6010 ensures strong, leak-proof welds, contributing to the integrity and long service life of critical civil infrastructure.

- Heavy Equipment & Agricultural Machinery: Repair and fabrication of heavy machinery often involve thick sections of steel. E6010's deep penetration is invaluable for these applications, ensuring strong and durable repairs.

- General Structural Steel Fabrication: From bridges and buildings to industrial frameworks, E6010 provides a reliable and efficient solution for welding various structural components, especially where fit-up might be less than perfect.

Figure 3: A professional welder utilizing Cellulose Electrode E6010 for a critical pipeline weld, highlighting its application in challenging field conditions.

5. Technical Advantages of **Cellulose Electrode E6010**: Why it Stands Out

The Cellulose Welding Rod E6010 is not just another special welding rod; it offers a distinct suite of advantages that cement its position as a top-tier choice for demanding welding tasks, particularly on carbon steel pipes.

- Deep Penetration and Robust Root Pass: The primary advantage of cellulose electrode E6010 is its forceful, "digging" arc. This enables exceptional penetration, crucial for creating strong, defect-free root passes, especially in open-root pipe welding where full fusion without backing is required. It effectively burns through rust, paint, or surface contaminants.

- Excellent Vertical Down (V-D) Capability: E6010 is renowned for its ease of use in the vertical down position, allowing for faster travel speeds and higher deposition rates in this orientation, which is highly beneficial in pipeline welding. The fast-freezing slag and fluid puddle are key to this capability.

- High Deposition Rates & Efficiency: Compared to other electrode types for specific applications (e.g., uphill), E6010 can offer higher deposition rates in vertical down and flat positions, contributing to increased productivity and reduced project timelines.

- Good Mechanical Properties: Despite its fast-freezing characteristics, weld deposits from cellulose electrode E6010 consistently exhibit excellent mechanical properties, including high tensile and yield strength, as well as good ductility, meeting stringent industry standards.

- Versatility in All Positions: While excelling in vertical down, E6010 is an all-position electrode, providing flexibility for welders tackling complex geometries and varied joint configurations.

- Tolerance to Contaminants: The vigorous arc and gas shield make E6010 forgiving on less-than-perfectly cleaned surfaces, burning through minor rust, paint, or mill scale, which is a significant advantage in field applications.

- Energy Efficiency and Cost-Effectiveness: Its high deposition rates and ability to perform quickly translate to energy savings and reduced labor costs per weld, contributing to the overall economic efficiency of projects. Furthermore, its reliable performance reduces the need for reworks, saving both time and resources.

- Corrosion Resistance (Indirect): While the electrode itself doesn't provide inherent anti-corrosion properties to the base metal, the strong, defect-free welds it produces are less susceptible to corrosion initiation points compared to welds with porosity or inclusions. Proper post-weld treatment often applied to carbon steel further enhances anti-corrosion measures.

6. Choosing Your Partner: Manufacturer Comparison and Quality Assurance

Selecting the right manufacturer for your cellulose electrode E6010 is as crucial as understanding the electrode itself. A reputable manufacturer doesn't just produce electrodes; they ensure consistent quality, provide technical support, and stand by their product's performance. When evaluating suppliers, consider the following:

- Certifications & Standards: Verify that the manufacturer adheres to international quality management systems like ISO 9001 and that their products meet specific welding standards such as AWS A5.1. Certifications from bodies like ABS, DNV, Lloyd's Register also signify adherence to marine and offshore standards.

- Raw Material Sourcing: A commitment to using only premium-grade raw materials ensures the purity and consistency of the electrode's flux and core wire.

- Manufacturing Precision: Look for manufacturers employing advanced extrusion and baking technologies that guarantee uniform coating thickness and moisture control.

- Quality Control & Testing: Robust in-house testing facilities, including chemical analysis, mechanical property testing (tensile, yield, impact), and radiographic inspection of test welds, are non-negotiable for consistent product quality. Our products undergo rigorous testing according to AWS D1.1 (Structural Welding Code – Steel) and API 1104 (Welding of Pipelines and Related Facilities) guidelines.

- Technical Support & R&D: A strong manufacturer invests in research and development to improve electrode performance and offers expert technical support to assist customers with application challenges.

- Industry Experience & Reputation: Companies with decades of experience in the welding consumables market, like us, have a proven track record of reliability and innovation. Our long-standing relationships with major contractors in the petrochemical and pipeline sectors attest to our product's consistent performance.

Figure 4: Secure and moisture-resistant packaging of Cellulose Electrode E6010, ensuring product integrity from factory to field.

7. Customization Solutions for Your Specific Needs

While the standard cellulose electrode E6010 covers a broad spectrum of applications, specific project requirements might demand tailored solutions. A responsive manufacturer can offer customization options to meet unique challenges:

- Diameter & Length Variations: While standard diameters (2.5mm to 6.0mm) are common, custom lengths or specific packaging configurations might be available for large-scale projects or automated welding setups.

- Special Packaging for Harsh Environments: For extreme humidity or remote site conditions, enhanced moisture-proof packaging can be provided to maintain electrode integrity.

- Batch-Specific Testing & Documentation: For highly critical applications, manufacturers can provide extra batch-specific test reports, material certifications (MTCs), and compliance documentation beyond standard requirements.

- Technical Consultation for Optimized Performance: Our expert team can provide in-depth consultation to help you select the optimal cellulose electrode E6010 parameters (e.g., current settings, technique) for challenging base materials or joint designs, ensuring maximum efficiency and weld quality.

8. Real-World Application Cases and Customer Success Stories

Our commitment to quality and performance is best demonstrated through the successful application of our Cellulose Welding Rod E6010 in diverse and challenging environments. Here are a few representative scenarios:

Case Study 1: Major Cross-Country Pipeline Project

Challenge: A leading energy infrastructure company required a reliable steel welding electrode for constructing a 500-mile natural gas pipeline across varied terrain, including mountainous regions and wetlands. The primary concern was achieving consistent, high-integrity root passes on X52 and X60 carbon steel pipes under tight deadlines and challenging weather conditions.

Solution: Our Cellulose Welding Rod E6010 (5.0mm and 6.0mm) was selected for all root and hot passes due to its exceptional deep penetration, forceful arc, and superior vertical-down characteristics. Welders reported excellent arc stability even in windy conditions and minimal porosity, significantly reducing repair rates.

Outcome: The project was completed ahead of schedule, with weld integrity surpassing API 1104 standards. The client reported a 15% reduction in root pass rework compared to previous projects using other electrodes, directly attributing this efficiency gain to the consistent quality and performance of our cellulose electrode E6010.

Case Study 2: Offshore Platform Maintenance

Challenge: An offshore oil platform required urgent repairs to structural members and process piping, demanding a welding electrode that could perform reliably in humid, salty, and often windy offshore environments, with limited access for pre-cleaning.

Solution: Given the challenging conditions, our cellulose electrode E6010 with its inherent tolerance to contaminants and robust arc was chosen. Its ability to create strong, fusion-rich welds despite less-than-ideal surface conditions proved invaluable.

Outcome: Repairs were completed efficiently, restoring structural integrity and operational safety. The client noted the electrode's superior performance in the adverse environment, minimizing downtime for the critical platform.

Figure 5: Demonstrating the superior arc stability and deep penetration capabilities of Cellulose Electrode E6010 in action.

Frequently Asked Questions (FAQ) about **Cellulose Electrode E6010**

Commitment to Trustworthiness: Delivery, Warranty & Support

We understand that reliability extends beyond the product itself. Our commitment to you includes:

- Efficient Delivery Cycle: With streamlined logistics and robust inventory management, we ensure prompt processing and dispatch of your orders, aiming for a delivery timeframe that minimizes project delays. Typical lead times for standard orders are 5-7 business days, with expedited options available upon request.

- Comprehensive Quality Assurance: Every batch of Cellulose Welding Rod E6010 for Carbon Steel Pipes undergoes stringent quality checks and meets AWS A5.1 and ISO standards. We offer a product warranty against manufacturing defects, guaranteeing performance as per specifications.

- Dedicated Customer Support: Our team of welding engineers and customer service specialists is available to provide technical guidance, troubleshooting, and support from product selection to post-welding analysis. We are committed to fostering long-term partnerships built on trust and mutual success.

Conclusion: The Unwavering Strength of **Cellulose Electrode E6010**

The cellulose electrode E6010 stands as a testament to tried-and-true welding technology, continuously proving its worth in the most demanding environments. Its unparalleled deep penetration, exceptional vertical-down capabilities, and tolerance for less-than-ideal surface conditions make it the definitive choice for critical applications, especially in the oil & gas, petrochemical, and structural fabrication industries. As a leading manufacturer of this essential special welding rod, we are dedicated to upholding the highest standards of quality, innovation, and customer support. Choosing our Cellulose Welding Rod E6010 for Carbon Steel Pipes means opting for reliability, efficiency, and a partner committed to your project's success.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025