e7018 welding rod manufacturers

Understanding E7018 Welding Rod Manufacturers

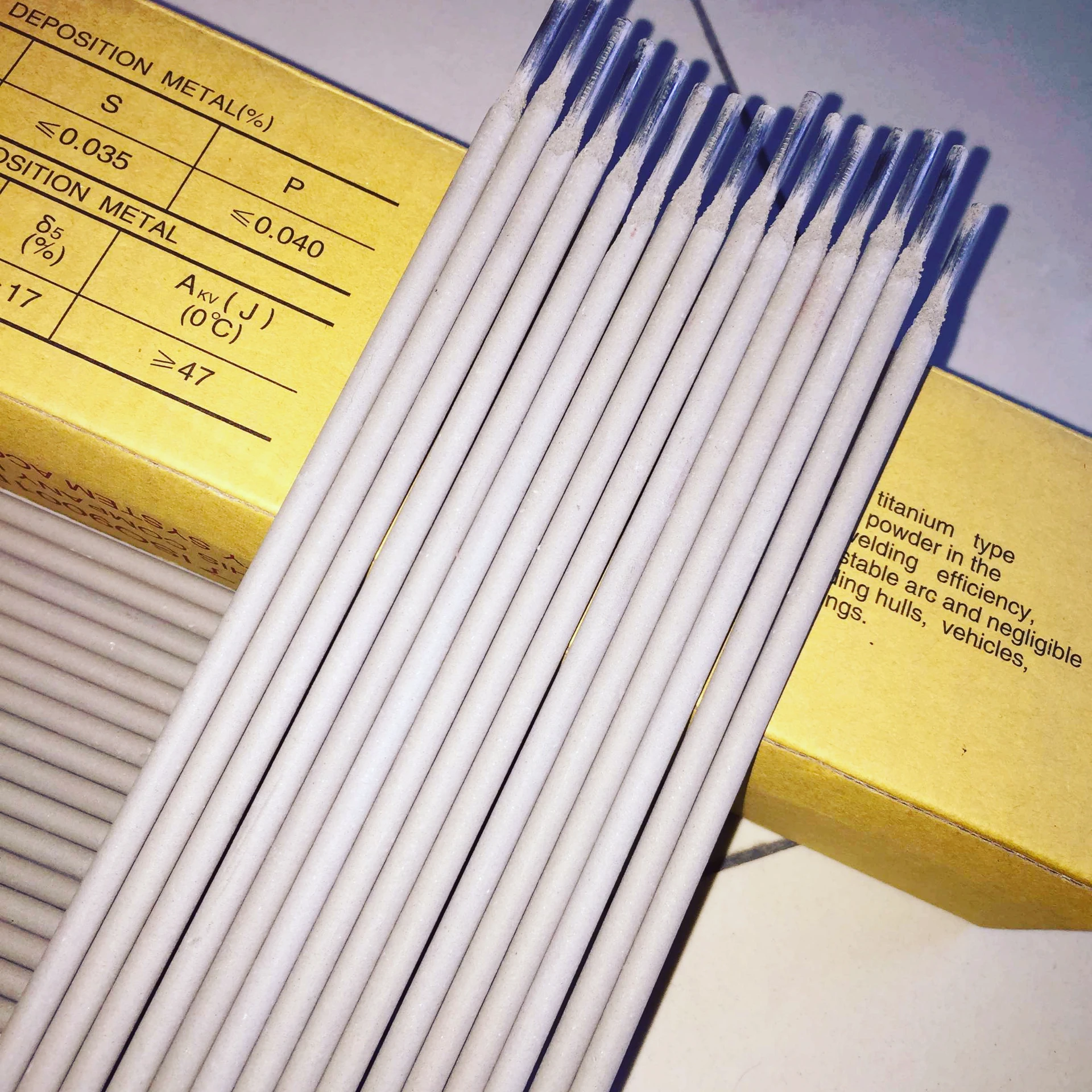

The E7018 welding rod is a key component in the world of welding, particularly for those engaged in low-hydrogen applications. As a type of electrode that is commonly used in arc welding, its popularity arises from its ability to produce strong, high-quality welds for various materials. Manufacturers of E7018 welding rods play a crucial role in ensuring that welders and fabricators have access to reliable, efficient products that meet industry standards.

What is E7018?

The designation E7018 is derived from the American Welding Society (AWS) classification system. The E represents that it is an electrode, while 70 indicates the minimum tensile strength of 70,000 psi. The 1 signifies that it can be used in all positions, and 8 denotes the low-hydrogen content, which minimizes the risk of cracking and makes it suitable for welding high-strength steels and other materials.

Importance of Quality Manufacturing

The quality of E7018 welding rods is essential for achieving desired weld properties. Manufacturers must adhere to stringent standards and rigorous testing procedures to ensure that their products deliver consistent performance. This includes everything from the raw materials used to the manufacturing processes employed. High-quality E7018 rods must demonstrate excellent arc stability, good bead appearance, and minimal spatter, while also being easy to use in various welding positions.

Key Manufacturers in the Industry

e7018 welding rod manufacturers

Several renowned manufacturers specialize in the production of E7018 welding rods. Companies like Lincoln Electric, Miller Electric, and ESAB are recognized for their commitment to quality and innovation. Each manufacturer invests in advanced technology and research to enhance the properties of their welding rods, ensuring they meet the evolving needs of welders across different industries.

These manufacturers not only produce E7018 rods but also offer a range of complementary products, including welding machines, fillers, and safety equipment. This comprehensive approach allows them to provide integrated solutions for welding professionals, enhancing productivity and safety on the job.

Certifications and Standards

When selecting an E7018 welding rod, it is crucial to consider certifications and compliance with industry standards. Look for products that have been certified by organizations such as the American National Standards Institute (ANSI) or the Canadian Standards Association (CSA). These certifications ensure that the welding rods meet specific performance criteria and provide assurance of their quality and safety.

Conclusion

In conclusion, E7018 welding rod manufacturers play a vital role in the welding industry by producing high-quality electrodes essential for strong and reliable welds. Understanding the significance of quality manufacturing, the key players in the market, and the importance of certifications helps welders make informed decisions when selecting their welding rods. As technology continues to advance, so too will the innovations in E7018 welding rods, ensuring that welders can achieve the best results in their projects. Whether for structural applications or fabrication work, E7018 rods remain a staple for professionals looking to deliver quality and durability in their welding tasks.

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025