Top Suppliers for Electrode Stick Welding Equipment and Accessories

The Rise of Electrode Stick Welding Suppliers A Comprehensive Overview

Electrode stick welding, often referred to as manual metal arc (MMA) welding, is a popular and versatile welding technique used in various industries, from construction to manufacturing. With the growing demand for durable and cost-effective joining methods, the importance of reliable electrode stick welding suppliers has surged. This article examines the key aspects of electrode stick welding, the challenges faced by suppliers, and the factors driving growth in this sector.

Understanding Electrode Stick Welding

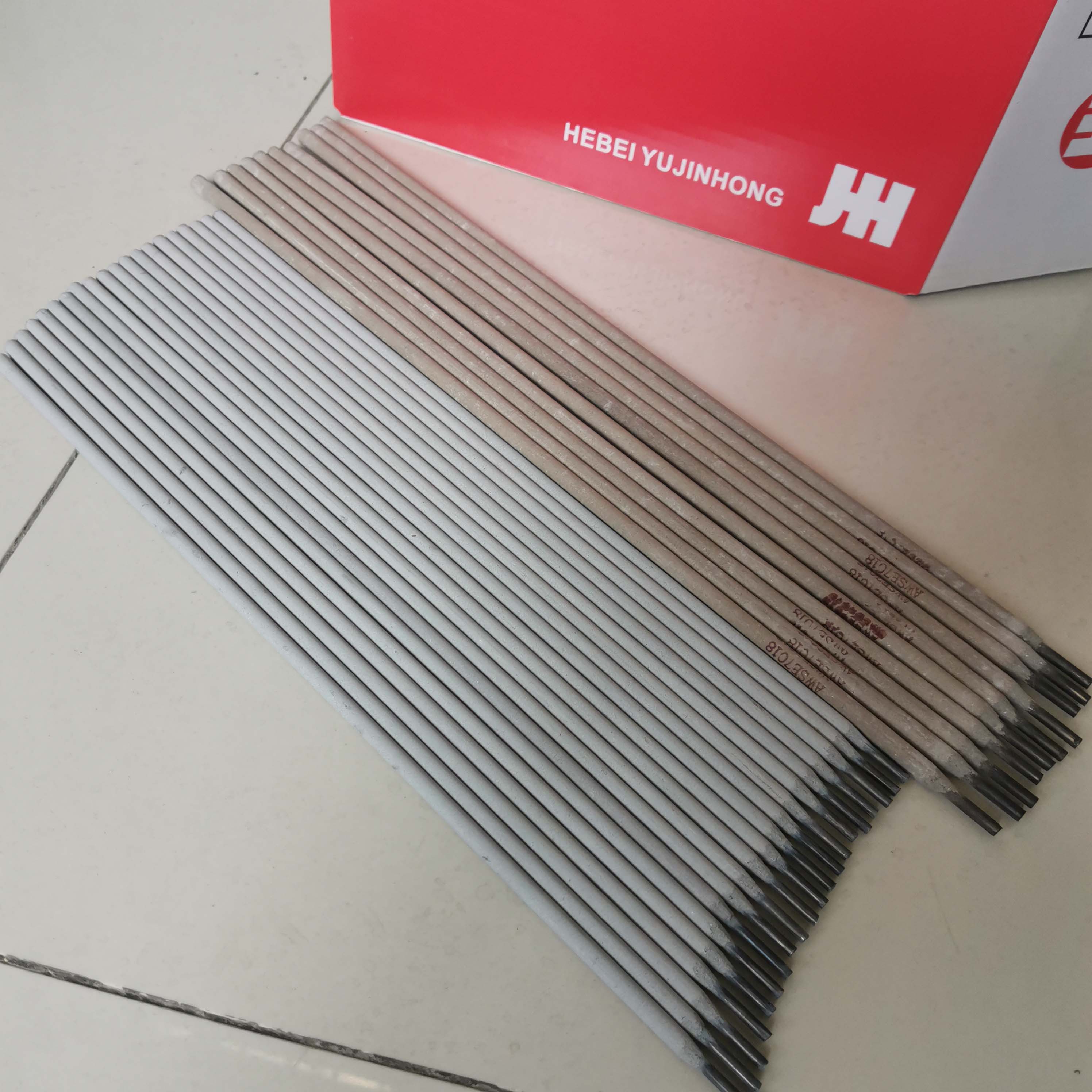

Electrode stick welding involves the use of a consumable electrode coated in flux. The electrode is heated by an electric arc that forms between it and the workpiece, causing both to melt and fuse together. This process not only allows for strong joints but also provides suitable penetration and minimal distortion, making it ideal for welding thick materials, even in outdoor conditions.

The simplicity and portability of stick welding make it a favorite among professionals and DIY enthusiasts alike. Whether it's for repairing farm equipment or constructing large structures, the technique is valued for its adaptability and efficiency.

The Role of Suppliers

Electrode stick welding suppliers play a crucial role in the industry by providing quality electrodes, necessary equipment, and support services. The demand for these products has been increasing, driven by the expansion of industries such as automotive, aerospace, and construction. Suppliers must ensure they offer a variety of electrodes suitable for different applications, ranging from low-hydrogen electrodes for critical applications to general-purpose electrodes for routine tasks.

Moreover, suppliers also provide support through technical advice, training, and even robotic welding solutions for more intricate jobs

. Catering to a diverse clientele requires an array of products and services adaptable to different welding environments and requirements.Challenges Faced by Suppliers

electrode stick welding suppliers

The welding supply industry is not without its challenges. One major issue is the fluctuation in raw material prices, which affects the cost of welding rods and related equipment. Suppliers need to navigate these fluctuations while maintaining competitive pricing for their customers.

Additionally, the global supply chain disruptions following the COVID-19 pandemic have impacted the availability of welding materials. Suppliers are required to build robust inventory management systems and establish reliable relationships with manufacturers to ensure consistent supply and avoid stockouts.

Furthermore, the industry is experiencing a shift towards more sustainable practices. Suppliers are increasingly being called upon to provide eco-friendly products and solutions, which can require significant investment in research and development to meet environmental standards.

Key Factors Driving Growth

Despite the challenges, several factors are driving the growth of electrode stick welding suppliers. With advancements in technology, welding equipment and electrodes are more efficient and easier to use than ever. Continuous improvements in products enhance user experience, reduce waste, and optimize welding processes, leading to higher quality output.

Additionally, the surge in infrastructure projects and manufacturing activities globally plays a vital role in the increasing demand for welding supplies. As countries invest in building and upgrading structures, the need for skilled welders and quality welding equipment rises correspondingly.

Moreover, the growing trend towards DIY projects has opened new markets for electrode stick welding. Hobbyists and small-scale entrepreneurs are increasingly engaging in welding activities, creating a new customer base for suppliers.

Conclusion

The landscape of the electrode stick welding supply industry is evolving rapidly, influenced by technological advancements, changing consumer behavior, and the need for sustainable practices. Suppliers must remain adaptive, focusing on providing high-quality products and exceptional customer support to thrive in this competitive market. As the demand for welding solutions grows, those who can navigate the challenges while embracing innovation will undoubtedly lead the way in shaping the future of electrode stick welding. As industries evolve, the role of reliable suppliers becomes even more critical in ensuring the sustainability and efficiency of welding practices across the globe.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025