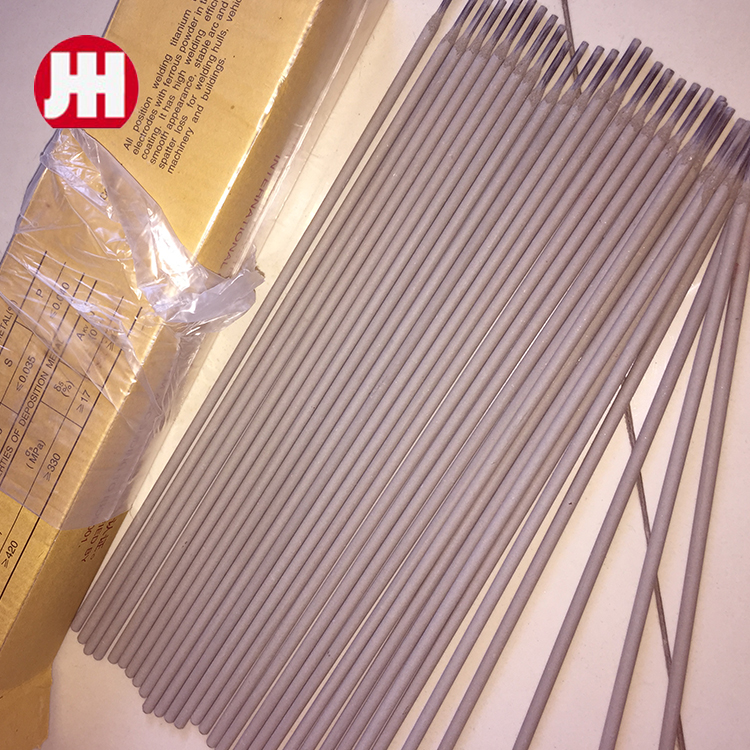

E7018 Welding Rods: Premium Low Hydrogen Electrodes

The demand for advanced welding consumables continues to rise, especially in industries like petrochemical, power generation, construction, and shipbuilding. Among thousands of electrodes, the e7018 welding electrode – supported by standards such as AWS E7018 and with variants like e7018 1 welding rod – stands as an industry pillar for its unmatched reliability, mechanical strength, and performance in critical application environments.

Industry Overview & Market Insights – e7018 welding electrode Trends

According to the Grand View Research 2023 Report, the global welding consumables market was valued at USD 13.5 billion in 2022, with low-hydrogen stick electrodes (like E7018) contributing over 28% of the consumable demand. Their ongoing adoption in infrastructure upgrades, energy sector expansions, and shipbuilding propels the growth. The integration of automated welding lines and stricter industrial compliance (e.g., ISO 2560, ANSI/AWS A5.1 standards) further consolidates the reputation of E7018 as an engineered solution.

Technical Specifications: What Sets E7018 Welding Electrode Apart?

| Parameter | E7018 (Standard AWS) | Customize E7018 Welding ELECTRODE RODS | E7018-1 (High Toughness Variant) |

|---|---|---|---|

| Diameter (mm) | 2.5, 3.2, 4.0, 5.0 | 2.0, 2.5, 3.2, 4.0, 5.0 | 2.5, 3.2, 4.0 |

| Length (mm) | 300, 350, 400 | 300, 350, 400, customizable | 350, 400 |

| Welding Current (A) | 80-210 (depending on diameter) | 70-240 (extra fine tuning) | 75-220 |

| Mechanical Strength (MPa) | ≥490 | ≥510 | ≥520 |

| Impact Toughness (J at -30°C) | ≥ 27 | ≥ 34 | ≥ 47 |

| Coating Type | Low-Hydrogen, Iron Powder | Refined low-hydrogen, corrosion-resistant | High-toughness, moisture resistant |

| Applicable Standard | AWS A5.1, ISO 2560 | AWS A5.1, ISO 2560-B, ISO 9001:2015 | AWS A5.1, EN ISO 2560-A |

Manufacturing Process of E7018 Welding Electrode: Step-by-Step Flow

Material Highlights & Testing Standards

- Steel Core Material: Premium low-carbon steel; impurity-controlled, tensile ≥ 510MPa.

- Coating: Low-hydrogen, high-adhesion mineral binder; special silicate matrix enhances slag removal.

- Tested to:

ISO 2560, AWS A5.1, ANSI Z49.1 - passing X-ray, mechanical (tensile, impact), and chemical composition analyses.

ISO 2560, AWS A5.1, ANSI Z49.1 - passing X-ray, mechanical (tensile, impact), and chemical composition analyses. - Longevity/Service Cycle: Up to 2x standard E6013 rods (Field feedback, 2023: structure welds remain defect-free for 10+ years in power plants).

- Industries Served: Petrochemical, offshore, shipbuilding, bridge construction, pressure vessel, boiler manufacturing, municipal pipeline projects.

Visual Data Insights

Technical Advantages of Customize E7018 Welding ELECTRODE RODS

- Superior Mechanical Strength: Enhanced alloying produces welds with yield strength ≥ 510MPa and impact toughness up to 53J (-30°C).

- Consistent Low Hydrogen Content: Controlled baking and packaging processes ensure ≤0.6% hydrogen, mitigating hydrogen-induced cracking (HIC).

- Anti-Corrosion & Weather Resistance: Special silicate/ferroalloy blend extends weld life in high-humidity or marine environments.

- Excellent Slag Removal: Advanced coating formula offers easy slag detach and smooth bead appearance, lowering post-weld labor cost by ~13% (industry average – 2023).

- Superior Arc Stability: Reliable for both AC and DC polarity, minimizing spatter and ensuring smooth, porosity-free welds.

- Certification: Conforms to ISO 9001:2015, ISO 2560, AWS A5.1; extensive third-party lab testing.

Manufacturer Comparison Table—How Customize E7018 Stands Out

| Brand/Manufacturer | Main Standard | Certifications | Tensile Strength (MPa) | Special Feature | Support & Customization |

|---|---|---|---|---|---|

| Lincoln Electric | AWS E7018 | ISO 2560, UL | ≥490 | Universal stick; all-positional | Limited |

| ESAB | AWS E7018-1 | ISO 2560 | ≥520 | High ductility | Yes |

| SteelToolsChina (Customize) |

AWS E7018, ISO 2560 | ISO 9001:2015, 3rd party | ≥510 | Fine-tuned alloy formula, anti-corrosion, custom sizes | Full OEM/ODM |

Customization & OEM Solutions

- Diameter: 2.0–5.0mm (custom alloys, dual-coating on request for extended shelf life in marine/overseas projects)

- Length: 250–450mm (customized as per site/automatic line requirements)

- Packaging: Moisture-proof vacuum packs; private labeling available

- Alloying Options: Nickel, Mo, Cr-Mo, targeted for cryogenic, high-temperature and sour service

- Export Support: Full documentation: COC, MSDS, EN10204 3.1 Mill Test Certificates

Application Scenarios: Real-World Performance

Challenge: Strong wind, salty mist, and high humidity.

Solution: Custom e7018 welding electrode rods with anti-corrosion coating.

Result: NDT X-ray inspection passed 100%/batch, less than 0.1% porosity rate (vs. 0.4% for generic rods).

Challenge: -35°C cryogenic temperature and thick plates.

Solution: E7018-1 variant for high impact toughness.

Result: Impact test >40J at -30°C; enhanced crack resistance; maintenance-free for 3+ years.

Challenge: Variable soil humidity; major leak risks.

Solution: Customize E7018 rods with moisture-resistant formula.

Result: Seamless pass on hydraulic pressure weld test, 21% reduction in on-field weld repairs.

Certification & Authority

-

Tested & Certified by

ISO 9001:2015,

ISO 9001:2015,

AWS A5.1,

AWS A5.1,

SGS, BV Laboratories

SGS, BV Laboratories

- Cooperative Projects with CNOC, Dongfang Electric, ABB Power, CHALCO, Sinopec, Korea Shipbuilding.

- 20+ Years of OEM/ODM export experience, serving 60+ countries.

- Full compliance with ISO 2560 and AWS A5.1.

FAQ on e7018 welding electrode (AWS, Custom, Application)

Delivery, Warranty & Support

- Lead Time: 7-18 days from PO confirmation; express production for urgent projects.

- Warranty: 12 months for manufacturing/weld defects. Technical consultation & on-site support available.

- After-Sale: Weld troubleshooting with NDT, sample archiving, and root-cause analysis reports.

- Global Logistics: FCA/FOB/CIF/DDU; export to 60+ nations; all packaging with moisture/vibration protection.

Why Choose Customize E7018 Welding ELECTRODE RODS?

- Compliant with the strictest global standards (AWS/ISO/ANSI), ensuring reliability for critical infrastructure, energy, and marine projects.

- Technical support is handled by AWS professional engineers, with full data traceability and customized manufacturing.

- Proven track record (20+ years) and continuous investment in R&D for optimized welding consumables.

- Competitive pricing and fast turn-around for custom orders. All e7018 welding electrode shipments covered by standard and extended warranty.

References & Further Reading

- "Advances in Low-Hydrogen Electrodes," Welding Journal, November 2007.

- "Welding Consumables Market Size," Grand View Research, 2023.

- Technical thread on electrode composition & selection: AWS Welding Forum

- "ISO 2560:2021 Welding consumables — Covered electrodes for manual metal arc welding of non-alloy and fine grain steels", ISO Official

- "E7018 Electrode Testing—Hydrogen Diffusivity & Impact Toughness": Welding & NDT Blog

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025