High-Quality 1.2mm Tubular Welding Wire from Reliable Factory Sources

The Rise of Tubular Welding Wire A Focus on 1.2mm Factory Production

In the world of welding, the choice of materials is crucial for ensuring the strength, durability, and quality of the final product. Among the various types of welding consumables, tubular welding wire has gained significant attention due to its unique properties and advantages. This article explores the production of 1.2mm tubular welding wire, delving into its manufacturing process, applications, and benefits.

Understanding Tubular Welding Wire

Tubular welding wire is a type of welding filler material designed to be filled with flux or metal powder, which helps in the welding process. This wire is used in conjunction with a shielding gas to protect the weld pool from contaminants in the atmosphere. Tubular wire offers improved feeding capabilities and is suitable for various welding processes, including gas metal arc welding (GMAW) and flux-cored arc welding (FCAW).

The Production Process of 1.2mm Tubular Welding Wire

The production of 1.2mm tubular welding wire involves several critical steps. First, high-quality steel wires are drawn to the desired diameter. During this initial step, manufacturers ensure that the wire exhibits the necessary mechanical properties and consistency to withstand the welding process and application stresses.

Once the wire is prepared, a combination of flux materials or metal powders is carefully filled into the tubular wire. This filling process is essential, as the correct composition of flux determines the performance and versatility of the welding wire. Manufacturers take great care to ensure that the flux material is homogeneously distributed throughout the wire to achieve optimal melting characteristics during welding.

Following this, the wire is closed and welded along its length to ensure that the flux remains contained. Rigorous quality control measures, including tensile testing and chemical analysis, are employed to guarantee that the produced wire meets industry standards and customer specifications.

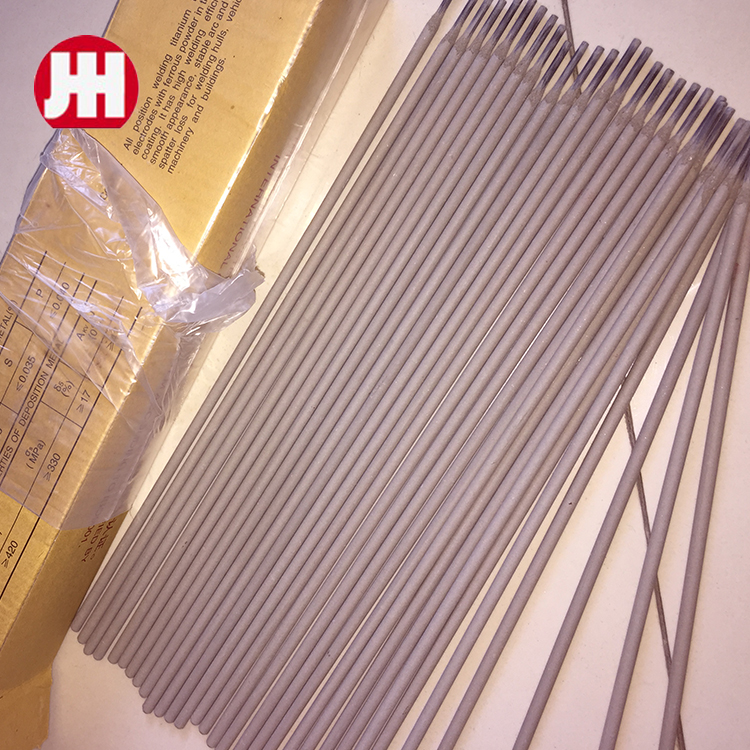

tubular welding wire 1.2mm factory

Applications of 1.2mm Tubular Welding Wire

The versatility of 1.2mm tubular welding wire makes it suitable for a wide range of applications across various industries. It is particularly favored in heavy industries like shipbuilding, construction, and fabrication due to its excellent weld stability and high deposition rates. The wire can be effectively used to weld thicker materials, making it an ideal choice for structural components requiring robust welds.

In addition to its use in traditional welding applications, 1.2mm tubular welding wire is also increasingly utilized in automated welding systems. The ability to maintain a consistent feed and provide high-quality welds enhances productivity in manufacturing environments. This automation trend reflects the industry's shift towards efficiency and precision, where the demand for high-quality welded structures continues to grow.

Benefits of Using 1.2mm Tubular Welding Wire

The use of 1.2mm tubular welding wire offers several advantages over conventional solid wires. One of the primary benefits is the increased deposition efficiency, which directly influences productivity. Higher filling factors mean fewer passes are required to achieve the desired weld quality, saving both time and resources.

Furthermore, the flux contained within the tubular wire provides additional benefits, such as improved arc stability, reduced spatter, and better slag removal. This results in cleaner welds and reduces the need for post-weld cleaning, contributing to overall efficiency.

Conclusion

As industries continue to evolve, the demand for high-quality welding materials remains steadfast. The production of 1.2mm tubular welding wire stands out as a key component in meeting these demands. Its unique properties, combined with a robust manufacturing process, ensure that it meets the needs of modern applications. As manufacturers focus on innovation and quality, the future of tubular welding wire looks promising, paving the way for enhanced performance in the welding industry.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025