Фев . 03, 2025 06:07

Back to list

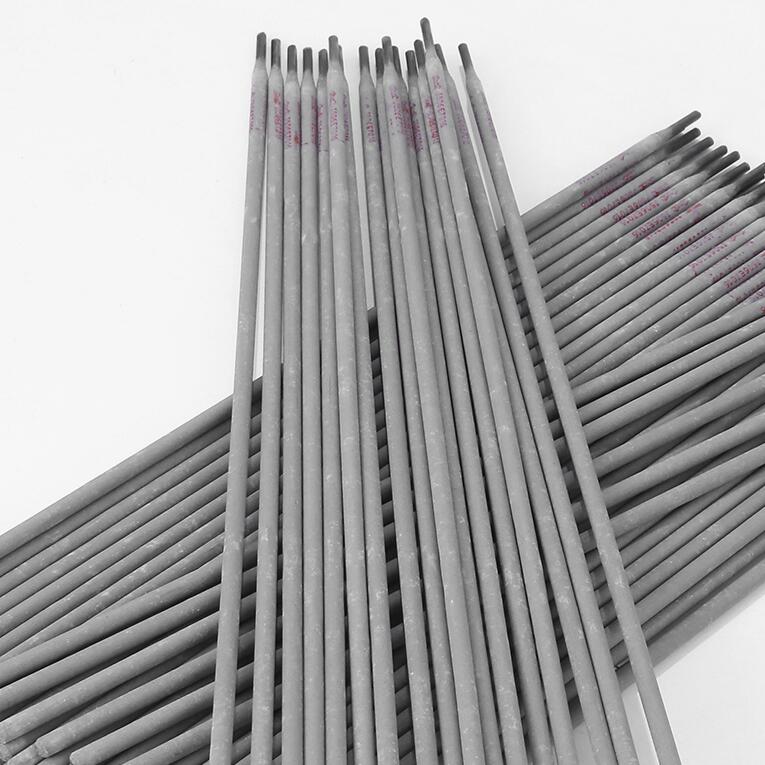

China welding rod 6013 welding electrodes aws e6013

Welding electrodes are crucial components in the realm of welding, serving as the filler material that facilitates the fusion of metals. Among the numerous types of welding electrodes available, the E6013 welding electrode stands out due to its versatility and ease of use, making it ideal for both novice welders and seasoned professionals. This article delves into an in-depth exploration of the E6013 welding electrode, shedding light on its composition, advantages, applications, and tips for optimal usage, ensuring that the welding process is both effective and safe.

Employing a slight drag technique when welding with the E6013 can enhance penetration and bead control. This involves angling the electrode slightly in the direction of travel, allowing the welder to maintain better visual control over the arc and the evolving weld pool. Additionally, maintaining a clean work environment is paramount; ensuring that the base metal is free from rust, paint, and other contaminants helps to achieve optimal results and extend the electrode's lifespan. While the E6013 is celebrated for its user-friendliness, understanding its limitations is also vital for ensuring safety and effectiveness. The electrode tends to perform best on materials that are not excessively thick, as it may struggle to achieve deep penetration on heavier gauge metals. For such applications, a different electrode with greater penetration capabilities might be required. Furthermore, welders should always adhere to standard safety protocols, wearing appropriate protective gear such as welding helmets, gloves, and flame-resistant clothing. In conclusion, the E6013 welding electrode continues to be a staple in the welding industry, prized for its ease of use, versatility, and ability to deliver clean, attractive welds across a range of applications. Its suitability for all-position welding and compatibility with various metals ensures that it remains a favored choice for both amateurs and professionals. By following best practices and recognizing its strengths and constraints, welders can fully leverage the capabilities of the E6013, executing projects with precision and confidence. As with any technical discipline, staying informed about the latest advancements and techniques in welding technology is essential for both hobbyists and professionals. Engaging with welding communities, participating in training sessions, and consulting expert resources can provide valuable insights and improve overall skill levels. With continuous learning and practice, the art of welding with the E6013 electrode can be mastered, opening the door to a world of creative and structural possibilities.

Employing a slight drag technique when welding with the E6013 can enhance penetration and bead control. This involves angling the electrode slightly in the direction of travel, allowing the welder to maintain better visual control over the arc and the evolving weld pool. Additionally, maintaining a clean work environment is paramount; ensuring that the base metal is free from rust, paint, and other contaminants helps to achieve optimal results and extend the electrode's lifespan. While the E6013 is celebrated for its user-friendliness, understanding its limitations is also vital for ensuring safety and effectiveness. The electrode tends to perform best on materials that are not excessively thick, as it may struggle to achieve deep penetration on heavier gauge metals. For such applications, a different electrode with greater penetration capabilities might be required. Furthermore, welders should always adhere to standard safety protocols, wearing appropriate protective gear such as welding helmets, gloves, and flame-resistant clothing. In conclusion, the E6013 welding electrode continues to be a staple in the welding industry, prized for its ease of use, versatility, and ability to deliver clean, attractive welds across a range of applications. Its suitability for all-position welding and compatibility with various metals ensures that it remains a favored choice for both amateurs and professionals. By following best practices and recognizing its strengths and constraints, welders can fully leverage the capabilities of the E6013, executing projects with precision and confidence. As with any technical discipline, staying informed about the latest advancements and techniques in welding technology is essential for both hobbyists and professionals. Engaging with welding communities, participating in training sessions, and consulting expert resources can provide valuable insights and improve overall skill levels. With continuous learning and practice, the art of welding with the E6013 electrode can be mastered, opening the door to a world of creative and structural possibilities.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025