Wholesale Submerged Arc Welding Wire for High-Quality Industrial Applications and Projects

Understanding Wholesale Submerged Arc Welding Wire

Submerged Arc Welding (SAW) is a highly effective and efficient welding process widely used in various industries, especially in heavy fabrication and construction. Central to this method is the use of high-quality welding wire that not only ensures strong welds but also maximizes productivity and reduces operational costs. Among the available options, wholesale submerged arc welding wire has emerged as a valuable resource for manufacturers and contractors alike.

What is Submerged Arc Welding?

Submerged Arc Welding is a process that utilizes a continuously fed wire electrode and a blanket of granular fusible flux, which protects the weld pool from atmospheric contamination. The name “submerged” comes from the fact that the arc and the weld pool are protected by a layer of flux or slag, which reduces spatter, fumes, and UV exposure, making it a safer and cleaner option compared to other welding techniques. The process is particularly advantageous for welding thick materials and is commonly used for welding structural components, pressure vessels, and shipbuilding.

The Importance of Quality Welding Wire

The quality of welding wire significantly impacts the overall job quality, efficiency, and the longevity of the welded joints. Wholesale submerged arc welding wire is produced to rigorous industry standards, ensuring high tensile strength, excellent ductility, and good metallurgical properties. When selecting welding wire, manufacturers must consider specific factors like wire diameter, chemical composition, and mechanical properties to suit their particular welding applications.

1. Wire Diameter The selection of wire diameter affects the heat input and penetration. Thicker wires generally allow for faster deposition rates, making them suitable for high-volume production tasks.

2. Chemical Composition The composition of the wire influences the hardness and toughness of the weld metal. It’s essential to choose a wire that provides compatibility with the base materials being welded, as well as the desired mechanical properties of the finished joint.

3. Mechanical Properties High-quality wires often demonstrate superior mechanical properties including yield strength, tensile strength, and impact toughness. These properties are crucial in applications where the welded components must endure significant loads or harsh conditions.

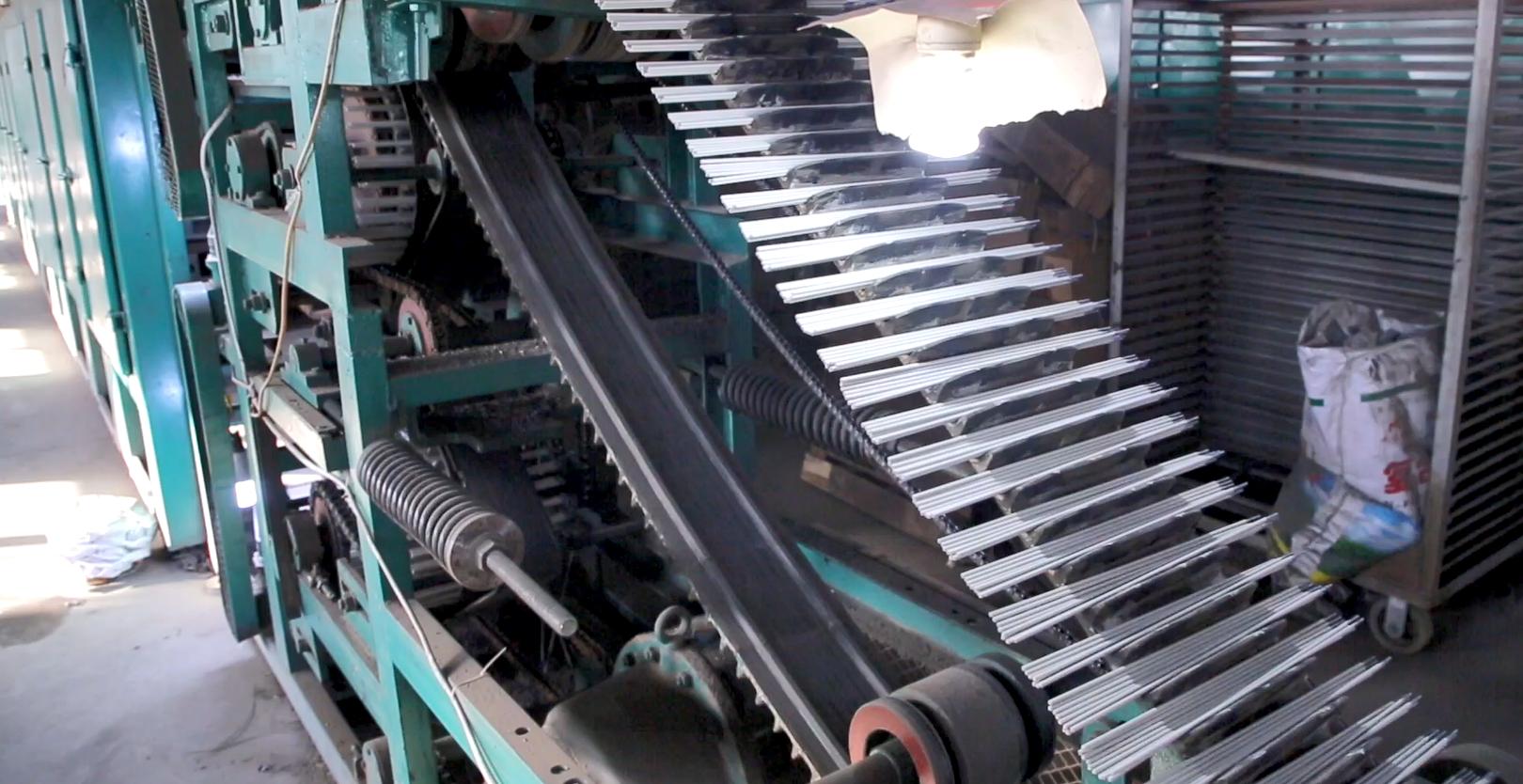

wholesale submerged arc welding wire

Benefits of Wholesale Purchasing

Purchasing submerged arc welding wire in wholesale quantities offers several advantages

- Cost Efficiency Bulk purchasing typically reduces the cost per unit, enabling businesses to save significantly on essential materials. This is particularly important for contractors engaged in large projects where material costs can escalate.

- Consistent Supply Engaging with wholesale suppliers ensures a consistent supply of welding wire, which is vital for companies that operate on tight schedules and need to maintain production without interruptions.

- Quality Assurance Established wholesale suppliers often provide assurance regarding the quality and compliance of their products with industry standards. This is crucial for maintaining the integrity of the projects and meeting regulatory requirements.

- Customization Wholesale suppliers usually offer opportunities for custom orders tailored to specific welding needs. This can include variations in diameter, spool sizes, and chemical compositions.

Final Thoughts

The choice of submerged arc welding wire can significantly influence the success of a welding project. By opting for wholesale purchasing, businesses can ensure they have access to high-quality materials at reduced costs, contributing to the overall efficiency and profitability of their operations. From large-scale industrial applications to specialized manufacturing tasks, the right wholesale submerged arc welding wire can make all the difference in achieving durable, high-quality welds. As industries continue to evolve and demand for efficient and reliable welding solutions increases, the importance of quality welding wire remains paramount. Investing wisely in welded products not only supports immediate project needs but also sets the foundation for long-term success in various welding applications.

-

Top Quality ER70S-6 Welding Wire High-Strength & ReliableNewsJun.06,2025

-

Premium 2.5 Welding Rods for Aluminium Arc Welding Wholesale SupplierNewsJun.06,2025

-

MINIMIG 100E Flux Core Welder Easy Aluminum Welding SolutionNewsJun.05,2025

-

Premium 309 Flux Core Wire Stainless Welding SolutionNewsJun.05,2025

-

China Quality Mig Aluminum Welding Wire - Low Melting PointNewsJun.05,2025

-

Premium E 6013 Welding Rods Wholesale & Supplier Direct from FactoryNewsJun.04,2025