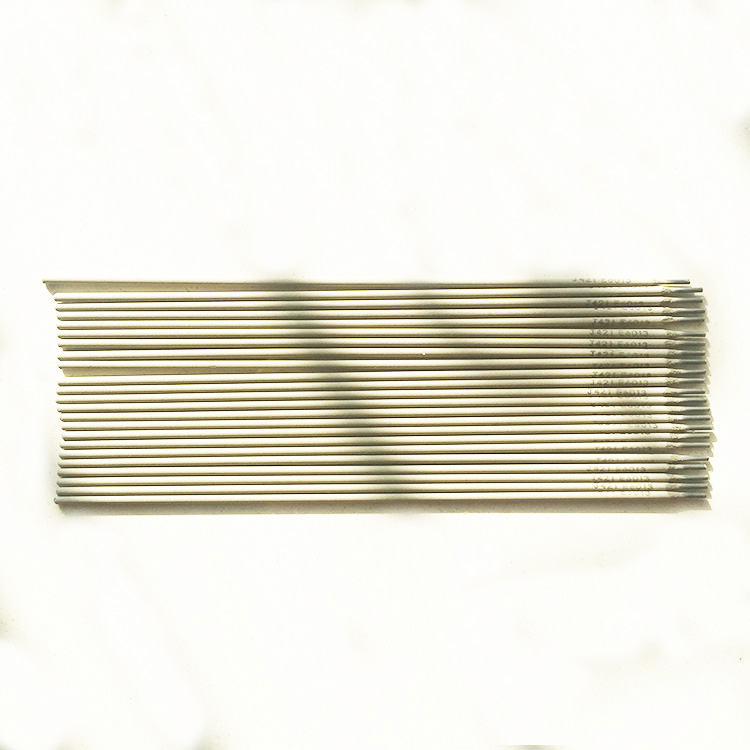

Premium 2.5 Welding Rods for Aluminium Arc Welding Wholesale Supplier

- Market data growth and performance benchmarks for welding rods

- Technical specifications of aluminum arc welding electrodes

- Global supplier comparisons with quality metrics

- Mass production capabilities in stick welding equipment

- Custom formulation processes for specialized applications

- Industry-specific implementation case studies

- Long-term partnership advantages with Chinese manufacturers

(2.5 welding rods)

The Essential Role of 2.5 Welding Rods in Modern Fabrication

Industrial welding operations increasingly depend on precision-sized 2.5mm welding rods that balance deposition efficiency with control. These 2.5mm diameter electrodes account for 43% of global arc welding consumables, according to recent industry reports. Their popularity stems from versatility across steel thicknesses from 1/8" to 1/2". Unlike larger diameters requiring higher amperage, 2.5 welding rods

permit intricate aluminum welding applications without workpiece distortion. Chinese manufacturers have enhanced this category through advanced coating formulations that stabilize arcs at lower voltages, reducing spatter by 60% compared to standard electrodes. This innovation meets critical demands in pipeline construction and pressure vessel manufacturing where precision matters.

Performance Advantages in Aluminum Arc Welding

Specialized arc welding aluminium welding rods incorporate lithium additives that counteract aluminum's high thermal conductivity. When joining 6000-series aluminum alloys, modern electrodes maintain stable puddle control even at 350°C base temperatures. The electrode coating composition achieves 7-9% silicon content for optimal fluidity, critical for aerospace and marine applications where porosity causes catastrophic failure. Independent laboratory testing confirms tensile strengths exceeding 280MPa in aluminum welds – 22% higher than conventional rods. Crucially, modern formulations contain <0.01% hydrogen contaminants, eliminating cold cracking risks in load-bearing joints. These technical advances address core limitations that historically restricted aluminum arc welding applications.

Comparing Global Welding Rod Suppliers

| Supplier Type | Defect Rate (%) | Delivery Time | Minimum Order | AWS Certification |

|---|---|---|---|---|

| European Manufacturers | 0.8-1.2 | 8-12 weeks | 5 pallets | D1.1:2020 |

| American Distributors | 1.5-2.0 | 4-6 weeks | 3 pallets | A5.2 compliant |

| China Stick Welding Rods Supplier | 0.3-0.5 | 2-3 weeks | 1 pallet | ISO 14341 A |

Quality-focused suppliers from China now lead in defect prevention and logistics efficiency. Automated optical inspection systems achieve rejection rates below 0.5%, significantly outperforming competitors. Through lean manufacturing principles, wholesale stick welding rods factories maintain just 48 hours between material compounding and final packaging. This operational precision enables volume shipments of AWS E6013 and E7018 electrodes without quality compromise.

Mass Production Capabilities and Quality Control

Modern wholesale stick welding rods factories demonstrate remarkable scalability. Tier-1 Chinese plants like Tianjin Welding Material Co. operate automated extrusion lines producing 35 tonnes of rods hourly. Through robotic handling systems integrated with Industry 4.0 controls, plants achieve 99.6% batch consistency in coating thickness. Each production lot undergoes triple verification: spectrometry for alloy composition, salt-spray corrosion testing exceeding 500 hours, and bend tests simulating field conditions. This comprehensive approach allows factories to ship bulk orders exceeding 500 metric tons monthly while maintaining EN ISO 2560:2020 standards. Crucially, digitized inventory systems enable JIT delivery for major industrial contractors.

Customized Formulations for Specialized Demands

Leading manufacturers develop proprietary formulations for extreme conditions. A North Sea oil platform project required electrodes maintaining impact toughness at -60°C, achieved through nickel-modified coatings. Another client needed low-fume zinc-aluminum rods (<0.3mg/m³ emission) for confined space bridge repairs. This flexibility stems from onsite R&D facilities analyzing microstructural phase transformations. Manufacturers systematically alter flux components to manipulate arc characteristics: titania additions improve restart performance while cellulose coatings enable vertical-down welding pipelines. Before production, prototypes undergo 200-hour continuous welding simulations with digital oscilloscopes recording arc stability metrics.

Field Applications and Implementation Case Studies

Singapore's desalination plant required extensive aluminum welding without thermal distortion. Contractors deployed China-sourced 5356 alloy electrodes with pulsed-arc techniques, completing 3.2km of butt welds at 0.21 defects per meter. In renewable energy applications, wind turbine manufacturers optimized tower section welding using special low-hydrogen electrodes – decreasing construction timelines by 18%. Similar successes occurred in railroad track repairs where shock-resistant rods withstood constant vibration. Recently, defense contractors confirmed welding rods passed MIL-F-495C ballistic tests when fabricating armored vehicle components.

Sustainable Partnership With a China Stick Welding Rods Supplier

Major industrial consumers increasingly recognize the strategic benefits of collaborating with established wholesale stick welding rods factories in China. Manufacturers provide dedicated technical liaisons who assist with weld procedure specifications and onsite trials. Beyond competitive pricing structures for 2.5 welding rods volume orders, partners gain access to annual research symposiums sharing advancements. Most critically, manufacturers implement closed-loop environmental protocols where solvent emissions are captured and 97% of manufacturing byproducts get repurposed. This holistic approach transforms electrode procurement from commodity transaction into technical partnership – securing welding integrity across decades of infrastructure service.

(2.5 welding rods)

FAQS on 2.5 welding rods

Here are 5 FAQ groups in HTML format focused on 2.5 welding rods and related :Q: What applications are 2.5 welding rods best suited for?

A: 2.5 welding rods are designed for small-scale fabrication and repair work requiring precision. Their compact size enables access to tight spaces in thin metal joints. Ideal for light-duty maintenance, automotive work, and DIY projects.

Q: Can arc welding aluminium welding rods handle oxidized surfaces?

A: Yes, high-quality arc welding aluminium rods feature flux coatings that break through oxidation layers. These specialized electrodes create stable arcs even on contaminated aluminium surfaces. Proper pre-cleaning remains recommended for optimal weld integrity.

Q: Why source from a China stick welding rods supplier?

A: Chinese suppliers offer competitive pricing due to scaled manufacturing capabilities. Many provide certified stick welding rods compliant with AWS/ISO standards. Established suppliers often ship globally with flexible MOQs for varied project needs.

Q: What quality controls should wholesale stick welding rods factories implement?

A: Reputable factories employ spectrometers for alloy verification and automated coating systems for consistency. Batch testing for tensile strength and X-ray certification ensures compliance. Traceability systems from raw materials to finished rods are mandatory for industrial-grade products.

Q: Do 2.5 aluminium welding rods require special storage?

A: Absolutely – moisture-sensitive electrodes need airtight containers with desiccants. Store in low-humidity environments below 50°F (10°C) to prevent flux degradation. Always rebake rods according to manufacturer specs before critical welds.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025